$0.00

Checkout- Brand: MAKTRANS-VB

- Product Code: remontg6T30E

Product model copied to clipboard

- Weight (kg): 10

- Availability: 19985

| Stock Place: | Availability: | Qty: |

| Poland | 9995 pcs. |

|

| Ukraine | 9990 pcs. |

|

- Product overview

- Shipping & Payment

- Questions - Answers (0)

- Related products (8)

Types of repair

Valve body housing repair

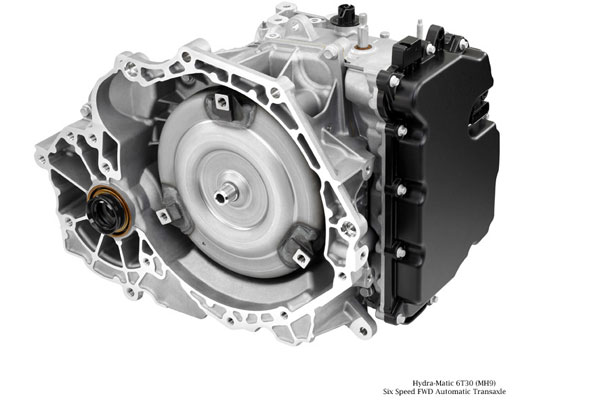

Six-speed automatic transmissions 6T30 (encoded by manufacturer MH9) and 6T40 (encoded by manufacturer MH8 / MHB) were developed by engineers of General Motors automotive concern for front-wheel drive cars with engine capacity up to 2.4 liters (6T30 - up to 2 liters, 6T40 - 2.4 liters ). Both transmissions came out in the Hydra-Matic series and are a continuation of the five-speed versions of the GM A/Ts. The external differences in the mechanical parts of the boxes are minimal and correspond to the maximum engine power (6T30 - up to 140 hp, 6T40 - up to 180 hp)

Automatic transmissions 6T30 and 6T40 with electrohydraulic control unit installed:

|

|

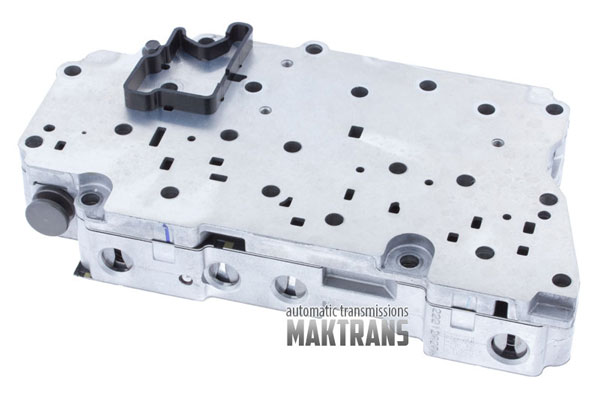

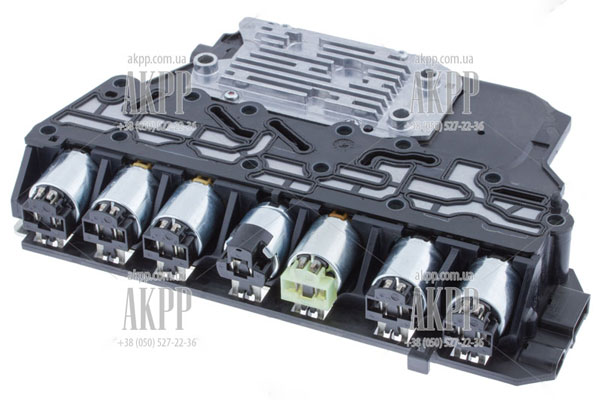

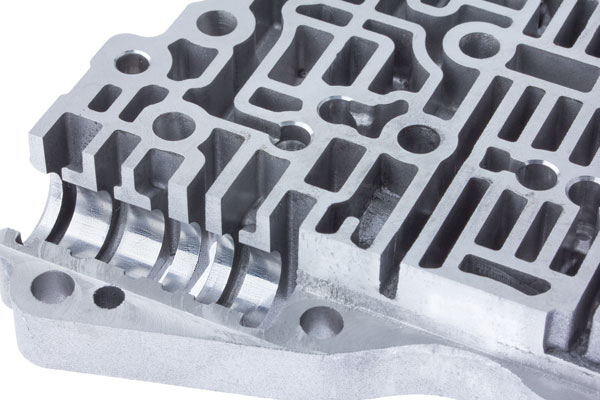

The mechanical part of the transmission is controlled by an electrohydraulic unit. Structurally the valve body consists of a demountable plate and a block of solenoids, the working fluid is the gear oil. The electronic control unit signals the electromechanical valves (solenoids), the solenoid core moves the plunger inside the channel of the hydroplate and changes the oil pressure. The change in pressure is transferred further along the channel inside the hydroplate to the actuator, as a result, the required change in the operating mode of the automatic transmission occurs.

The hydroplate in the assembly and the block of solenoids with the electronic control unit:

|

|

Such defects in the operation of the automatic transmission system as impacts and slippage during gear changes, loss of auto-neutral and the absence of a lock-up of the torque converter indicate a malfunction of the valve body.

To determine the defective node accurately, the diagnostic equipment is used. One of the signs of failure of the valve body is the error Chevrolet P0990 (High voltage in the transmission oil pressure sensor circuit), as well as other errors:

P0741 - Solenoid valve -torque converter clutch solenoid (TCC) -locked in the “off” position

P0776 - Clutch Solenoid Valve 2 (3.5, R) - locked in the “off” position

P0788 - Shift Timing Solenoid "A" High (Increased response time of solenoid A)

P0796 - Clutch Solenoid Valve 3 (4,5,6) - locked in the “off” position

P0842 – Low voltage of pressure sensor circuit

P0843 - High voltage of pressure sensor circuit

P0872 - Low voltage of pressure sensor circuit

P0873 - High voltage of pressure sensor circuit

P0877 - Low voltage of pressure sensor circuit

P0878 - High voltage of pressure sensor circuit

P0989 - Low voltage of pressure sensor circuit

P0073 - Transmission Fluid Pressure Sensor / Switch "C" Circuit High

P2714 - Pressure Control Solenoid "D" Performance or Stuck Off

P2723 - Clutch solenoid valve 5 (1,2,3,4) - locked in the “off” position

Errors obtained during diagnosis are divided into three groups:

1. Defects in the work of the block of solenoids.

2. Oil pressure sensor failure.

3. Failure of the valve channel of the valve body or plunger.

The problems with solenoids and pressure sensors are solved by replacing them with new original spare parts..

|

|

In the case of the valve body, the specialists of the Maktrans company recommend to make repairs. Repair is not only economically profitable, but also qualitatively does not differ from the purchase of a new valve body, and problems with the valve channel are solved by specialists based on many years of experience in servicing automatic transmissions. Studying the defects of valve bodies, experts of the Maktrans company came to the conclusion that the wear of the valve channel is caused by the mechanical action of microparticles in the hydraulic fluid acting as an abrasive. During operation, the mechanical components of the automatic transmission clog the transmission oil with chips resulting from the maximum mechanical forces at the contact points. The chips get into the oil and are carried around the entire body of the automatic transmission, falling into valve body too. Additional pollution occurs as a result of the destruction of clutches.

The untimely replacement of the transmission oil and the operation of the automatic transmission at the maximum torque results in premature failure of the valve body channels. As a result of wearout, the oil pressure in the channel of the valve body drops, which causes loss of control in one of the automatic transmission sections, this can be downshifting or upshifting, transition to auto-neutral mode, clutch operation, etc.

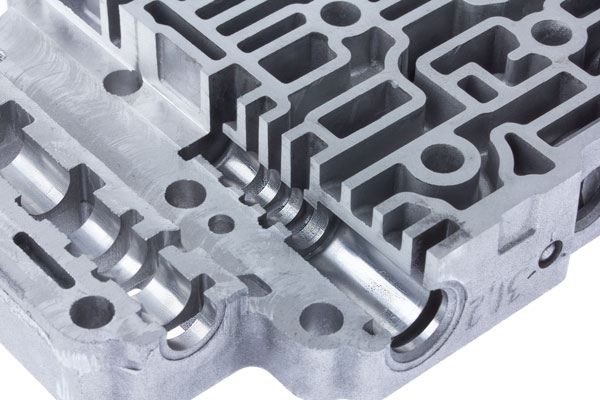

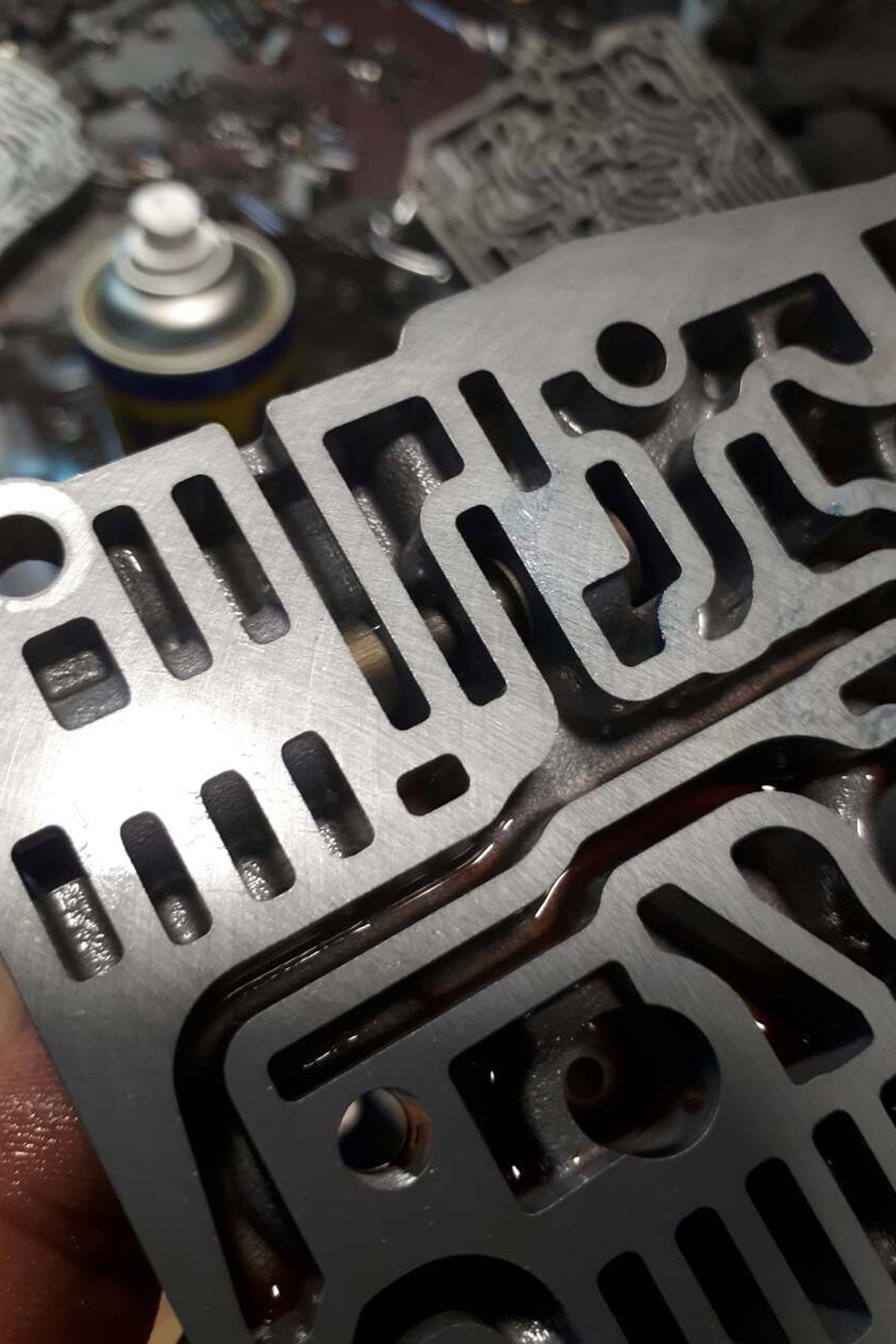

An example of the wearout of a valve channel in a section. Some traces of wearout are visible to the naked eye, the presence of the rest shows testing.

|

|

|

|

.To determine the integrity of the channel, Maktrans specialists use vacuum technology.

The plunger is inserted into the test channel, after which a reduced pressure is created. If the channel walls are in working order, then the pressure is not bleeding, if the pressure rises, then the channel walls are worked out.

|

|

|

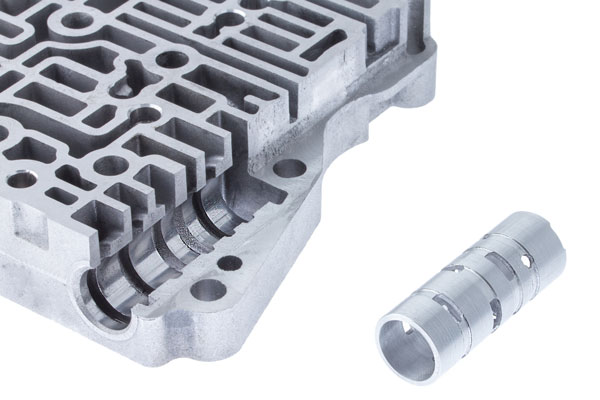

To prolong the life of the valve body, repair sleeves of the valve channels are used. The bushings are made on machines with digital control and exactly repeat the relief of the internal surface of the valve channel.

|

|

Before installing the bushing, the repair channel is bored, after which the repair bushing is pressed in.

|

|

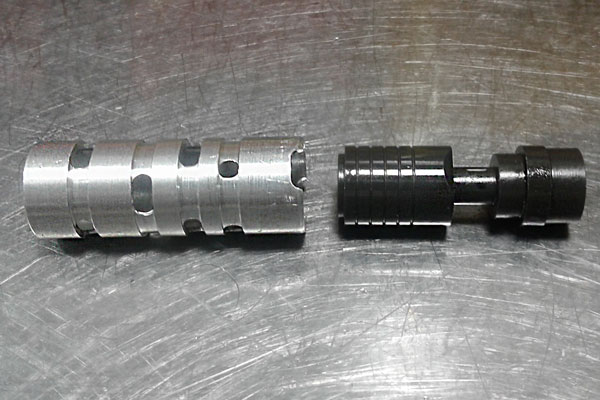

This is howready to install kits look like. If necessary, the plunger can be replaced with a new one.

|

|

|

|

Thus, the majority of the valve channels, including the solenoid channel of the torque converter lock up, the solenoid channel responsible for the oil pressure and the channels of the shift solenoids, are repaired. At the end of the repair, each valve body undergoes a complete check of the reconstructed sections. After installation in the car all modes of automatic transmission operation are checked. The valve bodies reconstructed by the specialists of the Maktrans company , correspond to the operating parameters of the new valve bodies and compete with the purchase of new and used parts. Warranty for repair 1 year.

AFL valve replacement

Compensator feed control valve replacing

Compensator feed control valve replacing

Symptoms:

Symptoms:

- Neutral spontaneous on/off

- Shocks when shfting from 1st to 2nd and from 2nd to 3rd gear

- Error during adaptation process

- Pressure sensor error

Chevrolet Aveo, Captiva Sport, Cruze, Epica

Chevrolet Aveo, Captiva Sport, Cruze, Epica

Payment

- PayPal (Payment to a PayPal account, without obtaining European VAT documents)

- Bank Transfer P2P only (Payment for private banking account, without the possibility of obtaining European VAT documents)

- Crypto Payment (If you want to make payment in cryptocurrency, without the possibility of obtaining European VAT documents)

- B2B sale with VAT ID: no VAT is charged (When buying for more than 300 euros, B2B sale with VAT IDfor countries VIES: no VAT is charged (With mandatory indication of the European VAT number and receipt of documents for the company) when buying for more than 300 euros

Shipping

We work with shipping companies like DPD, DHL, FedEx and we can ship worldwide. Shipping cost you can see during checkout and on product page (you can use button "Shipping Cost Calculator")