$0.00

Checkout- Brand: MAKTRANS-VB

- Product Code: U150VBREBUILD

Product model copied to clipboard

- Weight (kg): 10

- Availability: 999

| Stock Place: | Availability: | Qty: |

| Ukraine | 999 pcs. |

|

- Product overview

- Shipping & Payment

- Questions - Answers (1)

- Related products (12)

The automatic transmission of the U150 / U250 series is a popular 5-speed box with which almost all Toyota and some Lexus have been equipped since 2001 and until the introduction of the 6-speed transmission of the U660E in 2007. The transmission is designed and developed by the Japanese company Aisin Warner, it is constructively a logical development of four-gear U140 / U240 and many nodes are interchangeable.

There are many modifications for different engine volumes and front / all-wheel drive, as this box was aggregated with both a 2.4L inline motor Camry (U250E) and with a V6 3.5L RAV4 engine (U151F).

These boxes are very reliable as for the "iron" part and if the driver did not subject the transmission to high loads, did not slip in the sand or snow, and besides that he also changed the oil in time - even to 150-200 thousand kilometers can be done without any complaints on the iron part of the gearbox (state of the planetary rows, clutch drums) .

At the same time, as for the hydraulic part, in particular the valve body - the mileage affects in any case. The reason for this is that as a result of friction the frictional material of the friction plates, as well as the torque converter lock-up piston, gets into the oil and turns it into an abrasive. Finely dispersed particles in the oil first clog the solenoids, secondly, the tightness of the channels of the hydroplate is broken, since wearout occurs on the plungers and the walls of the channels.

We proceed to restore the valve body. First, we will tell you what repair options the are offered by the specialists of "Maktrans" and detail pricing.

Complex repair - includes all procedures from disassembly and troubleshooting to assembling an already repaired valve block. The cost consists of the cost of work performed and the cost of consumables. After the finding the defect, the master communicates with the client and announces the total cost of the repair, calculated as follows:

| Work | Price |

|---|---|

| Diagnosis (disassembly, washing, vacuum testing, visual inspection and inspection of plungers for jamming) | 150$ |

| Testing solenoids on the stand - $ 5 apiece. 7 solenoids. | 35$ |

| Solenoids regeneration - $ 40 per piece. In U150 as a rule, only 4 solenoids are repaired. | 160$ |

| Reaming the channels of the hydraulic plate and installing enlarged valves. Reaming of one hole is $ 20, the plunger is $ 11. We put 2 oversized plungers and 2 booster valves. 84 $ |

84$ |

| Assembly and final inspection | Free of charge |

Thus, a typical repair of the U250 will cost $ 379 and it is covered by a 1-year warranty with no mileage limitation. The price can differ both in the big, and in the smaller side.

The second option is the repair of individual parts of the hydraulic plate, this is the choice of customers who repair the boxes on their own. We can check and repair the solenoids, install a oversized plunger that the customer specifies, or test the plate by yourself, identify problem channels and repair. The price policy is the same as in the example above.

Content table

Diagnostics

We got a Toyota Camry 2.4L, U151E valve body. Symptoms are as follows:

1.Thumps when switching from the second to the third gear.

2.When the AT is heated there are slips on all gears.

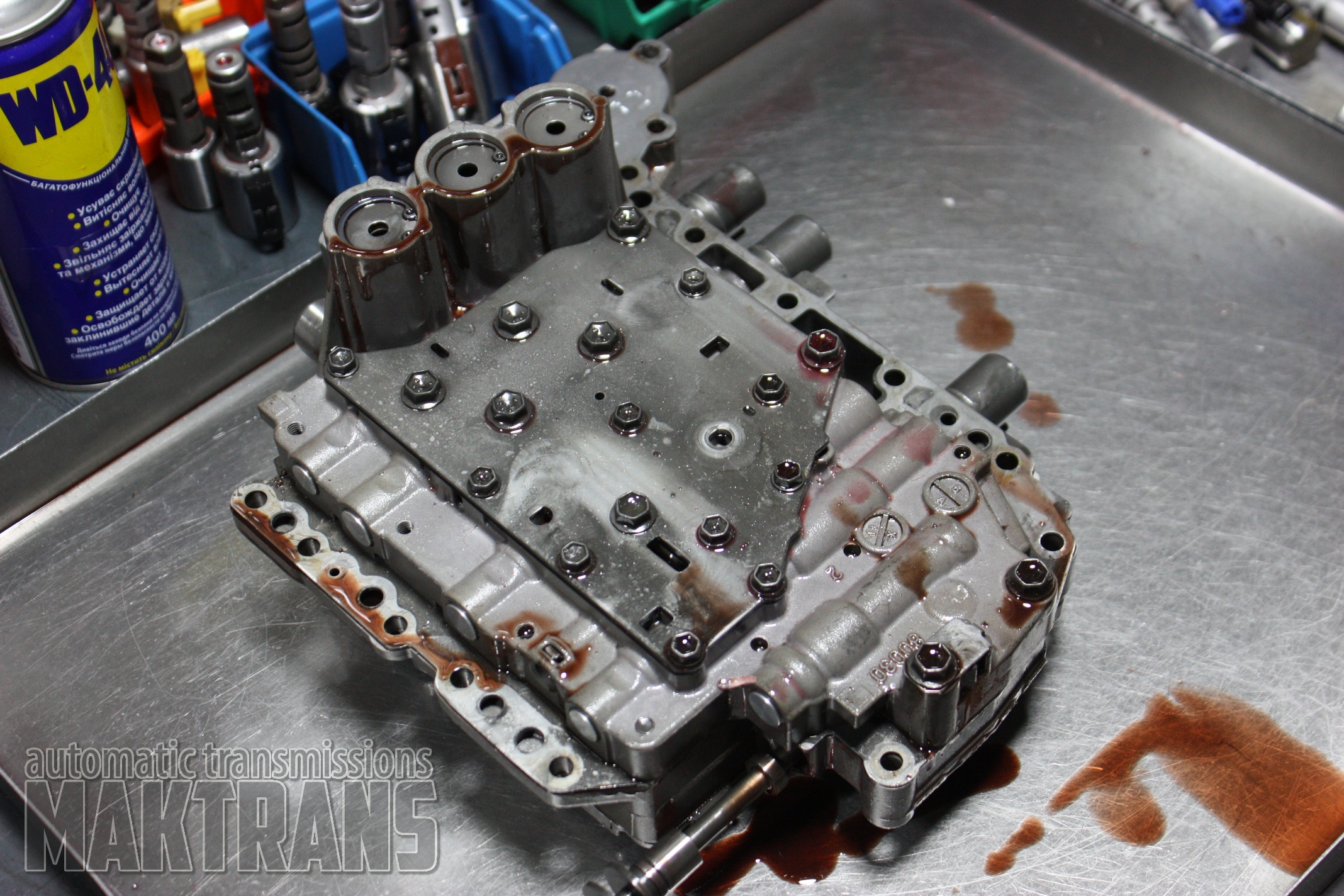

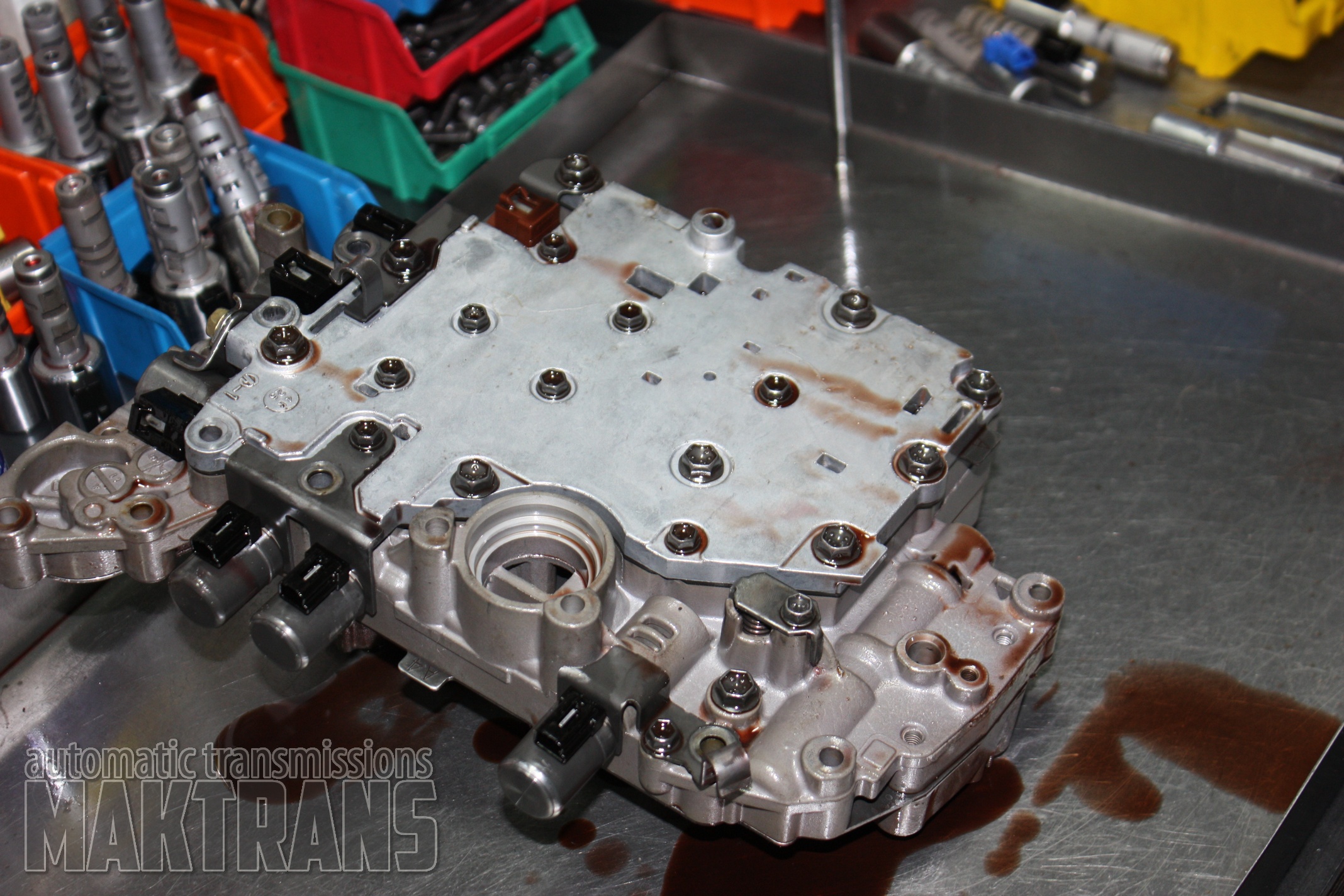

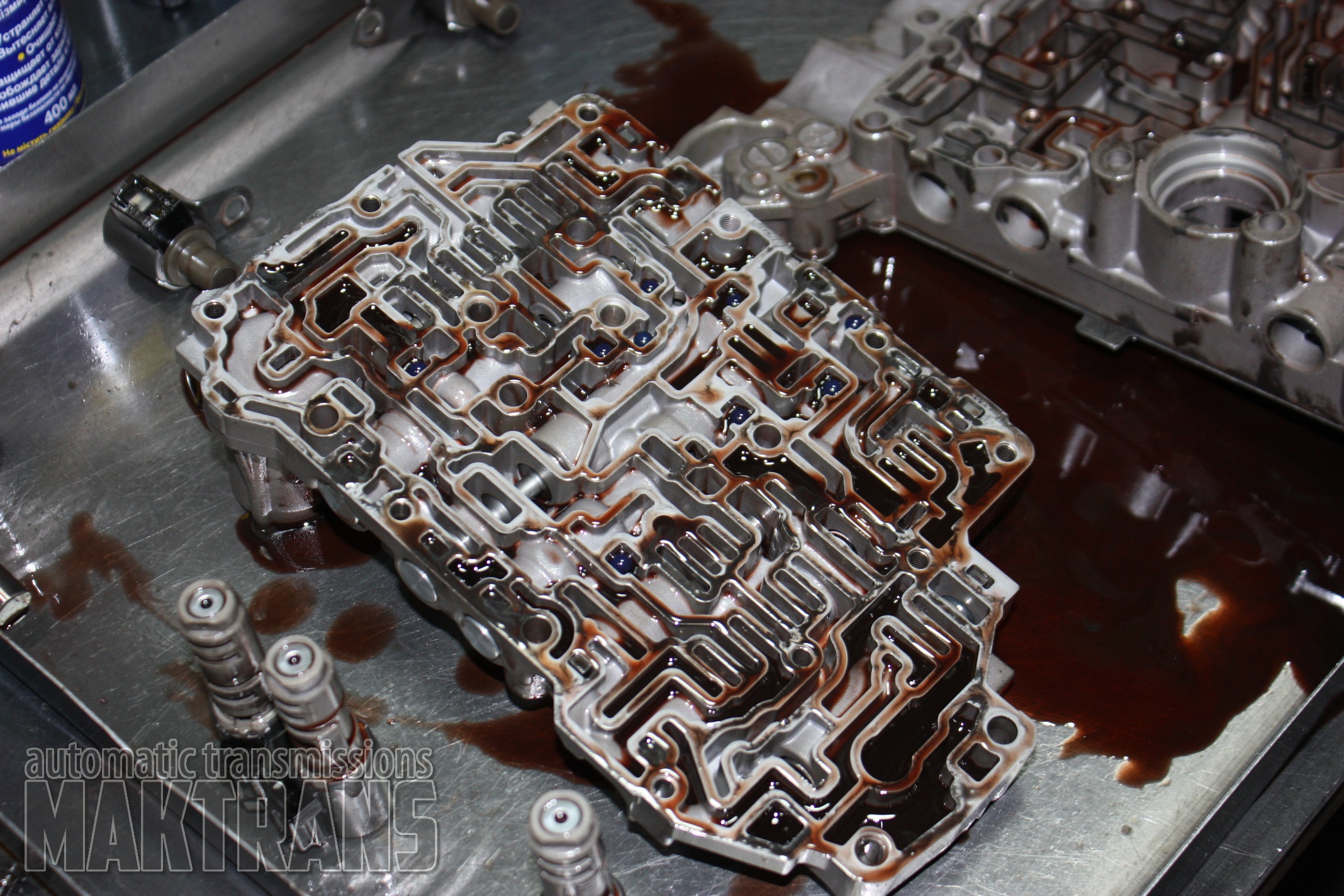

Vale body is on the master`s table

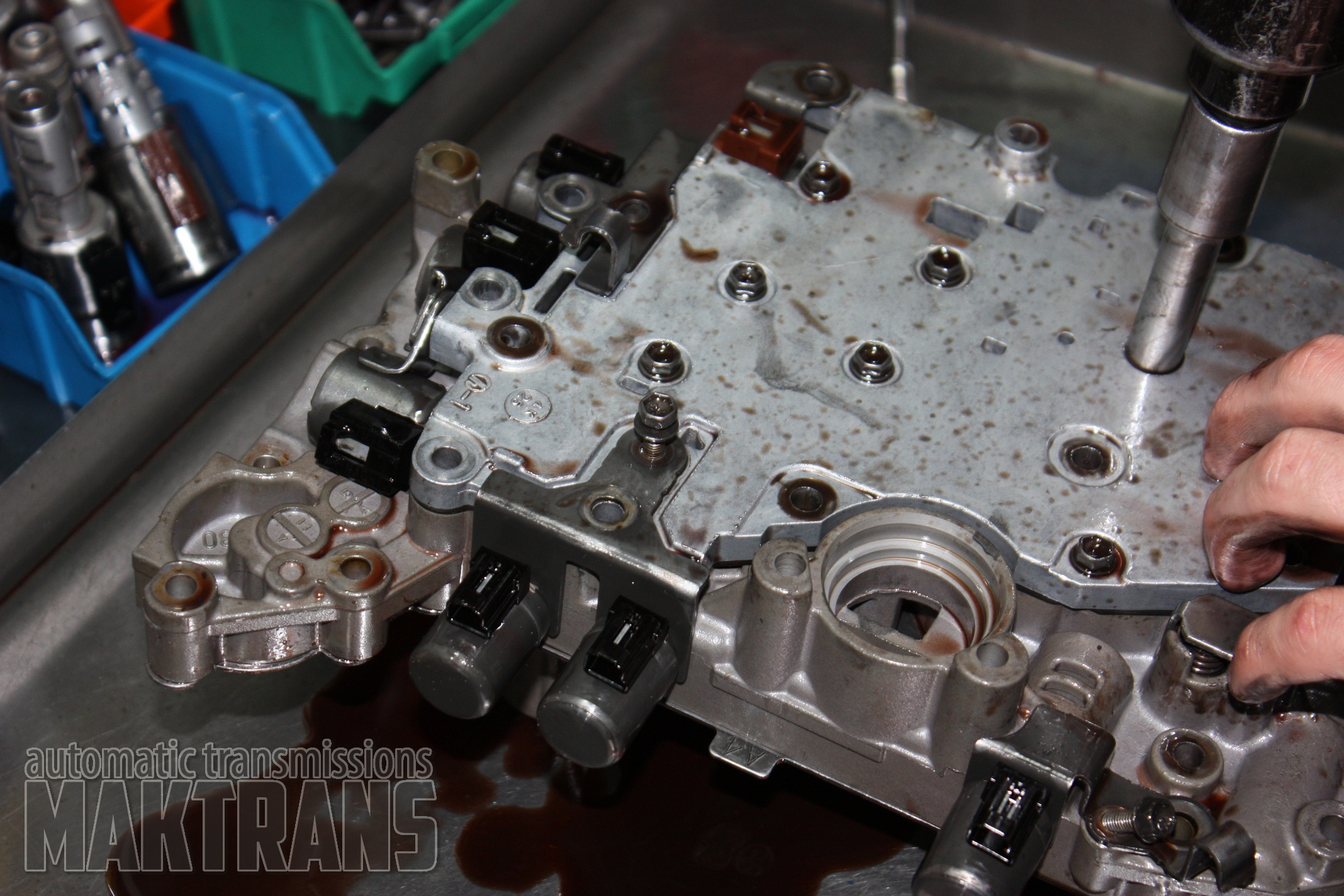

We are disassembling and looking. As always we remind you are not to rush during the disassembly, we immediately prepare something like a tray with cells where we can lay out the small parts that will be extracted from the hydraulic plate during the dismantling.

|

|

|

|

|

|

In the photo below - checkballs. Do not lose and remember the location of each, if you forget to install at least one during the assembly, or install it wrong - the valve block will not work properly.

We send the disassembled valvebody to an automatic washing machine. Such washes save time for repairers allow to achieve a very high level of cleaning of parts, but in some cases after washing, manual cleaning is still necessary if dirt remains in hard-to-reach places of the gearbox. In this case, use a soft (!) brush to clean the required area and blow it with air. We apply this kind of powder, it is good to launder and degrease even the case of boxes. Many novice repairers make a big mistake when they wash the valve block using different kinds of detergents in which there is an abrasive material, this is strictly prohibited. The material of the hydraulic plate is sufficiently soft aluminum, easily damaged.

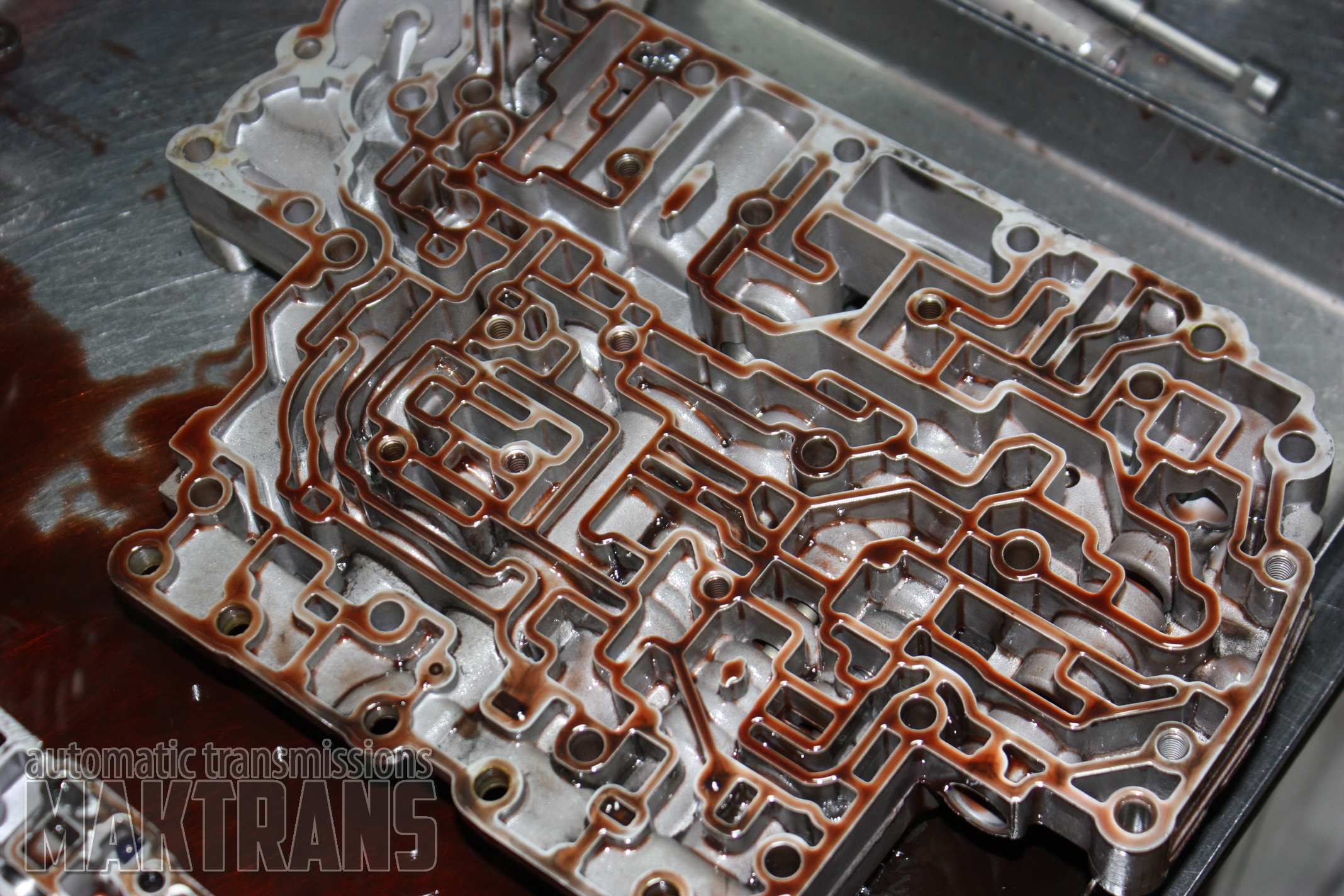

We return already washed up parts of the valve block to the valvebody repair department and proceed to a visual and vacuum check.

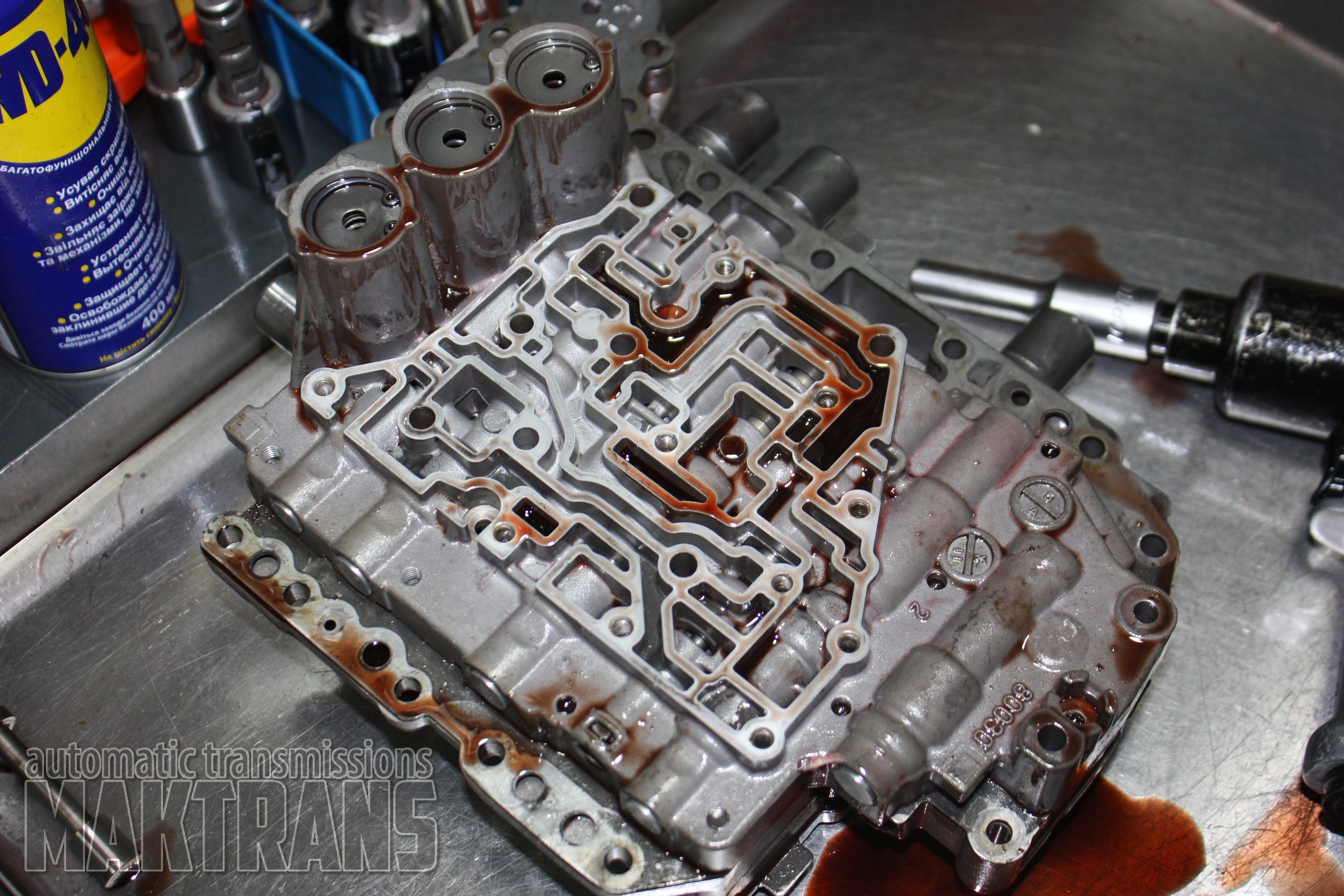

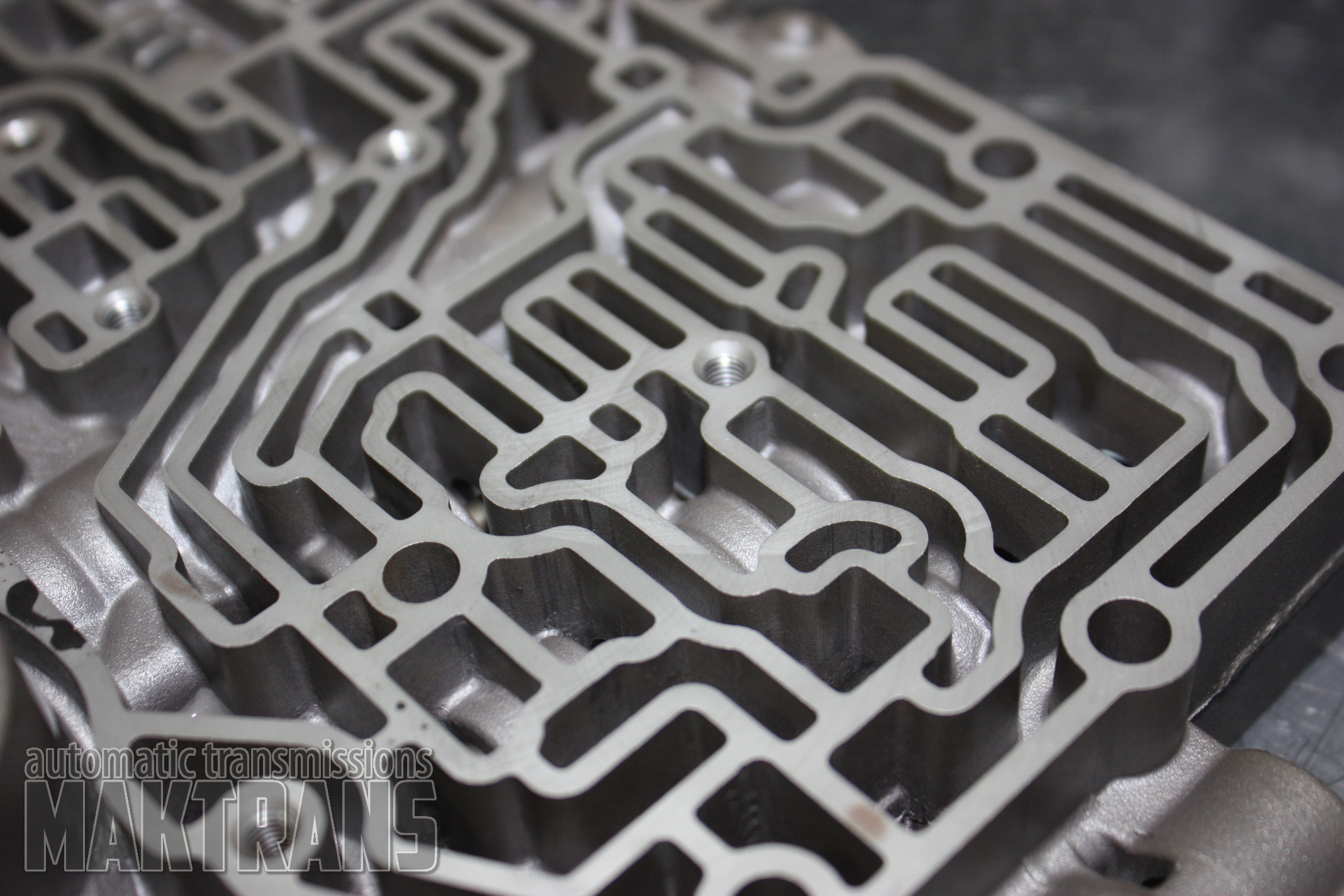

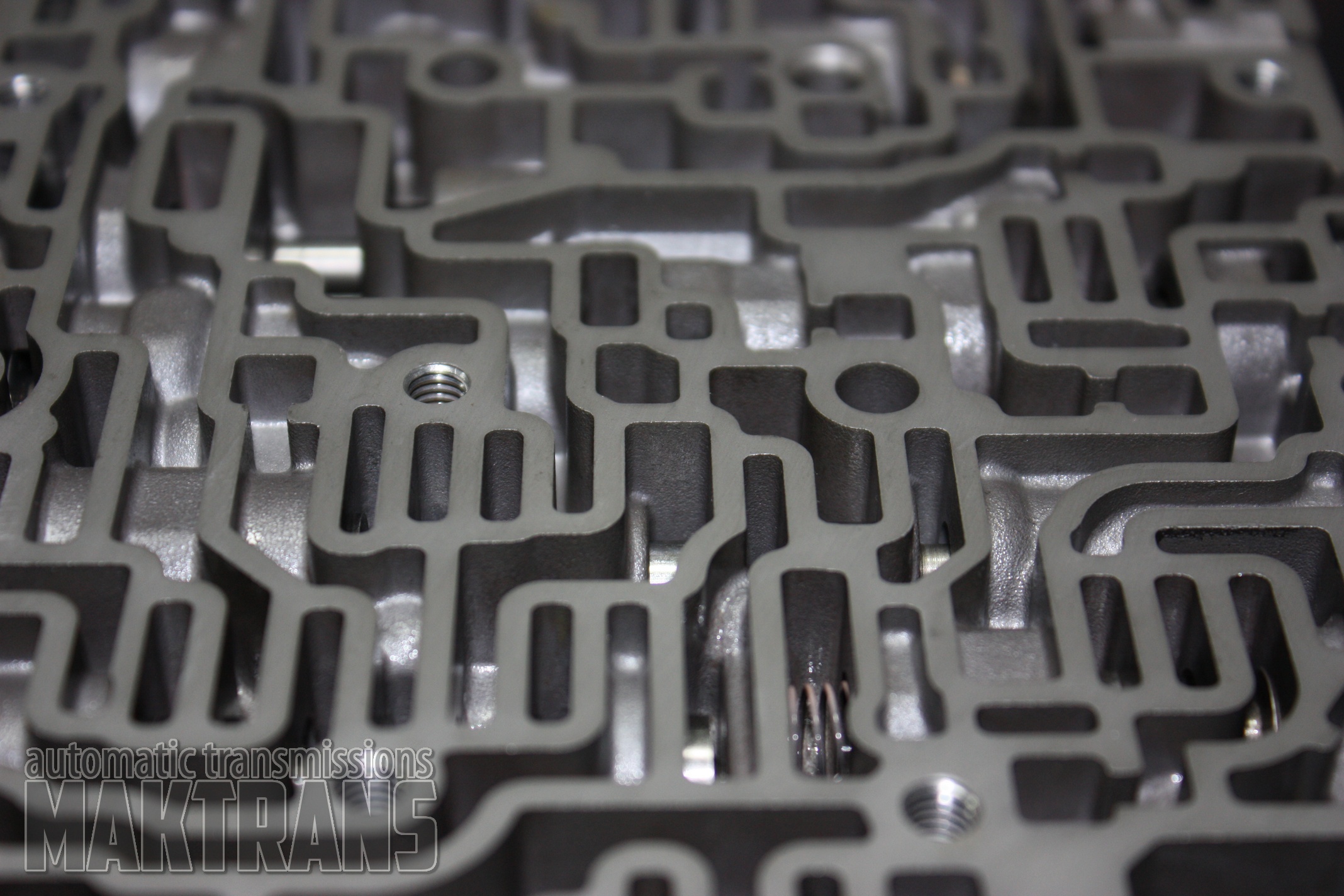

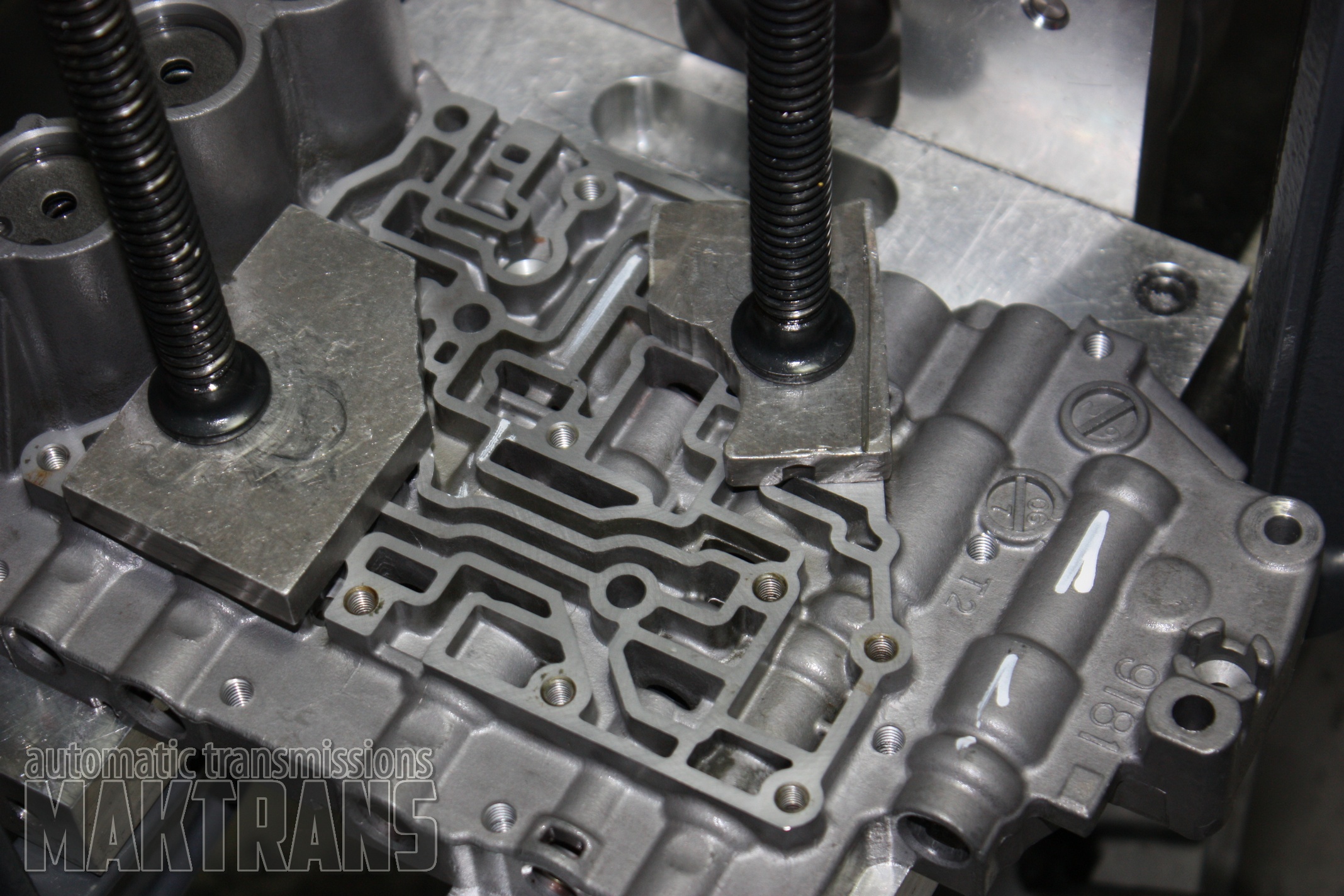

This is how clean hydraulic plate look like.

|

|

|

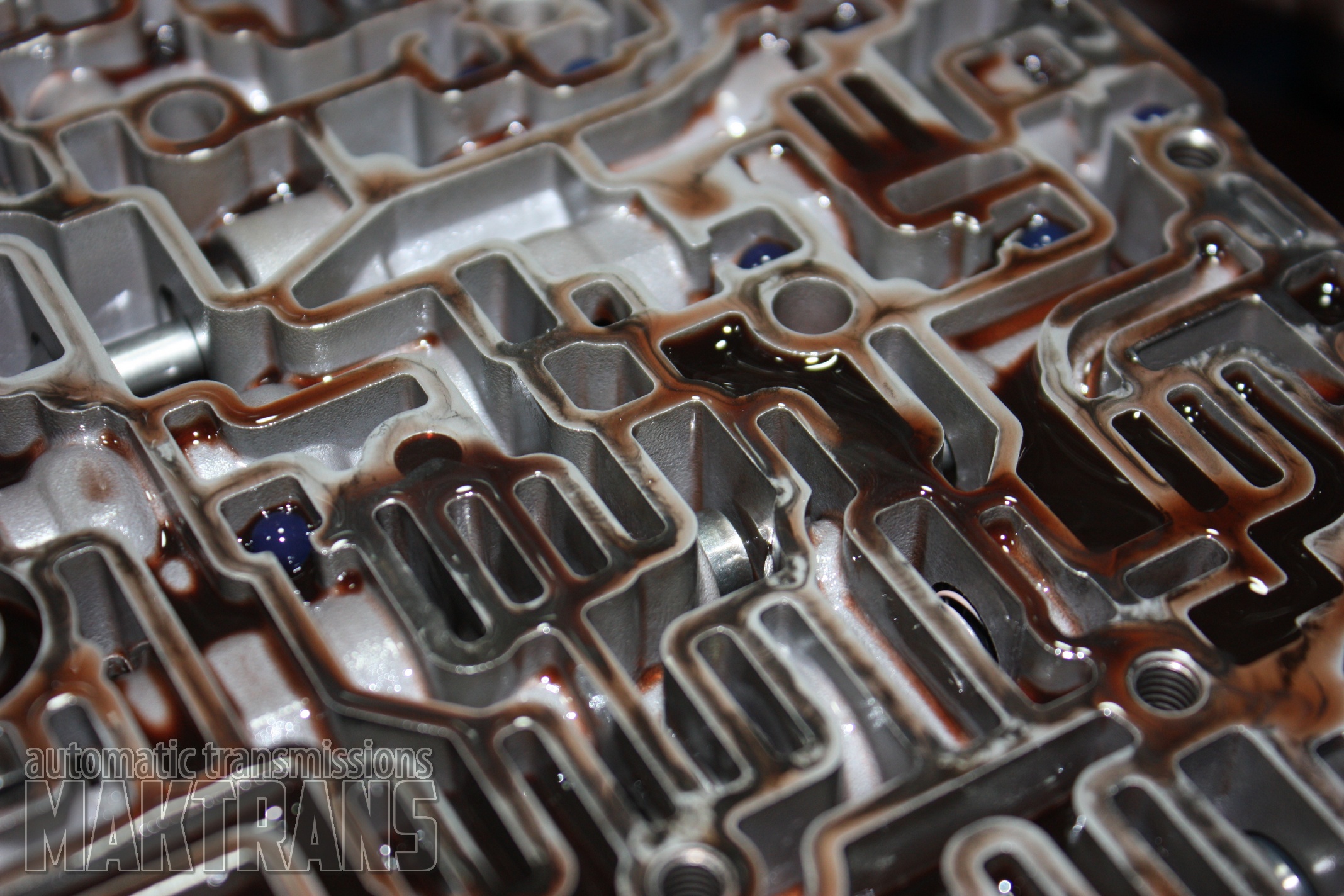

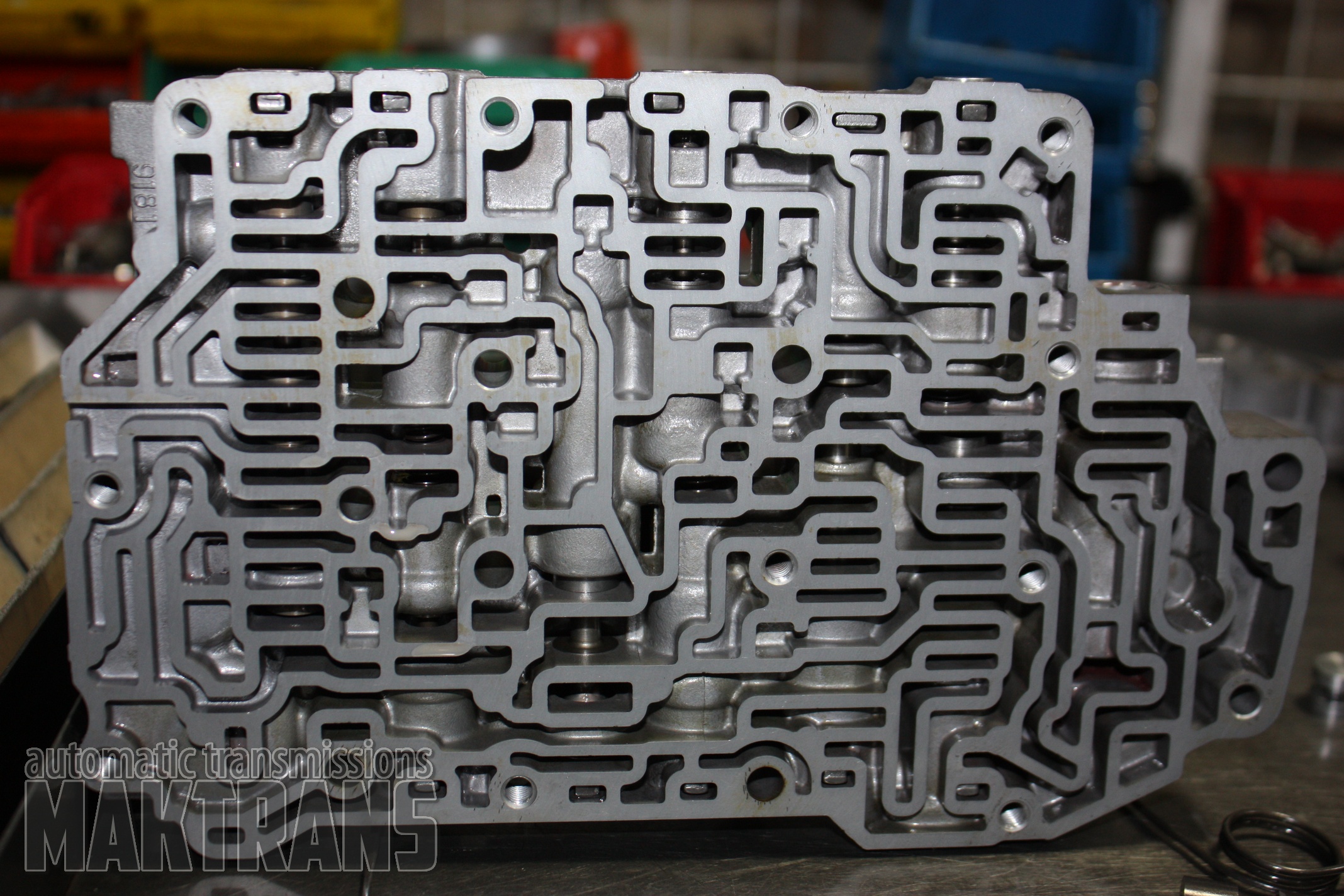

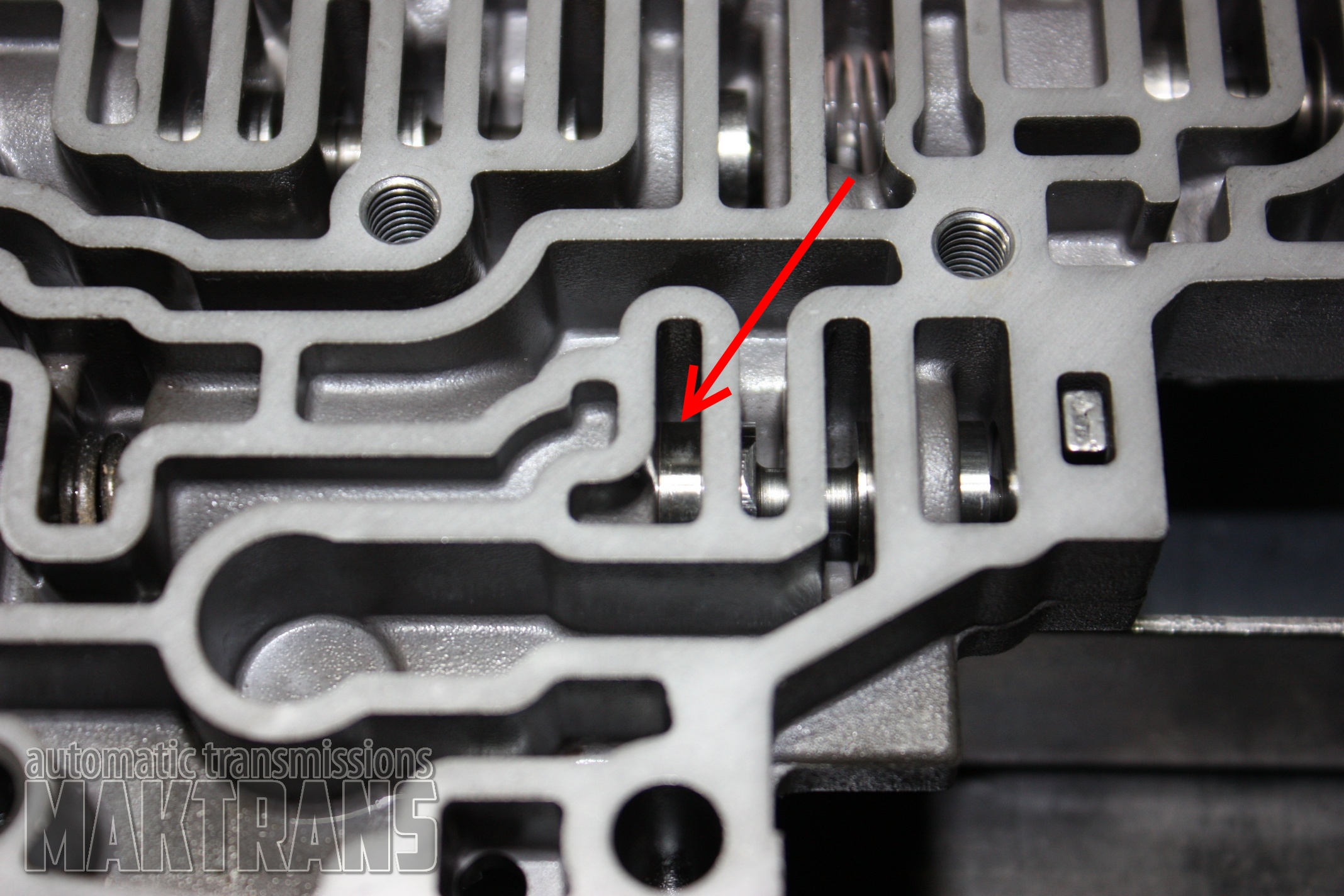

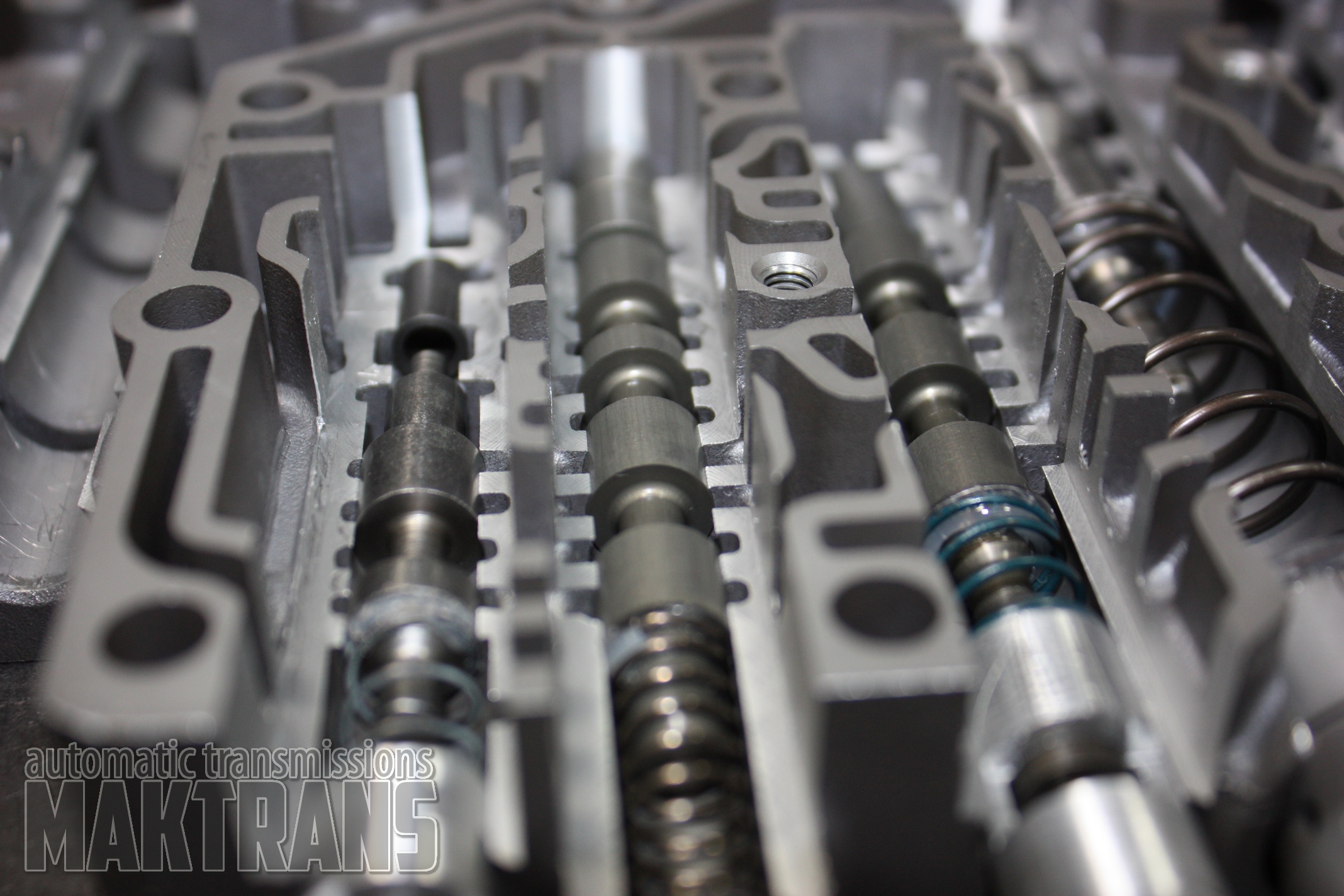

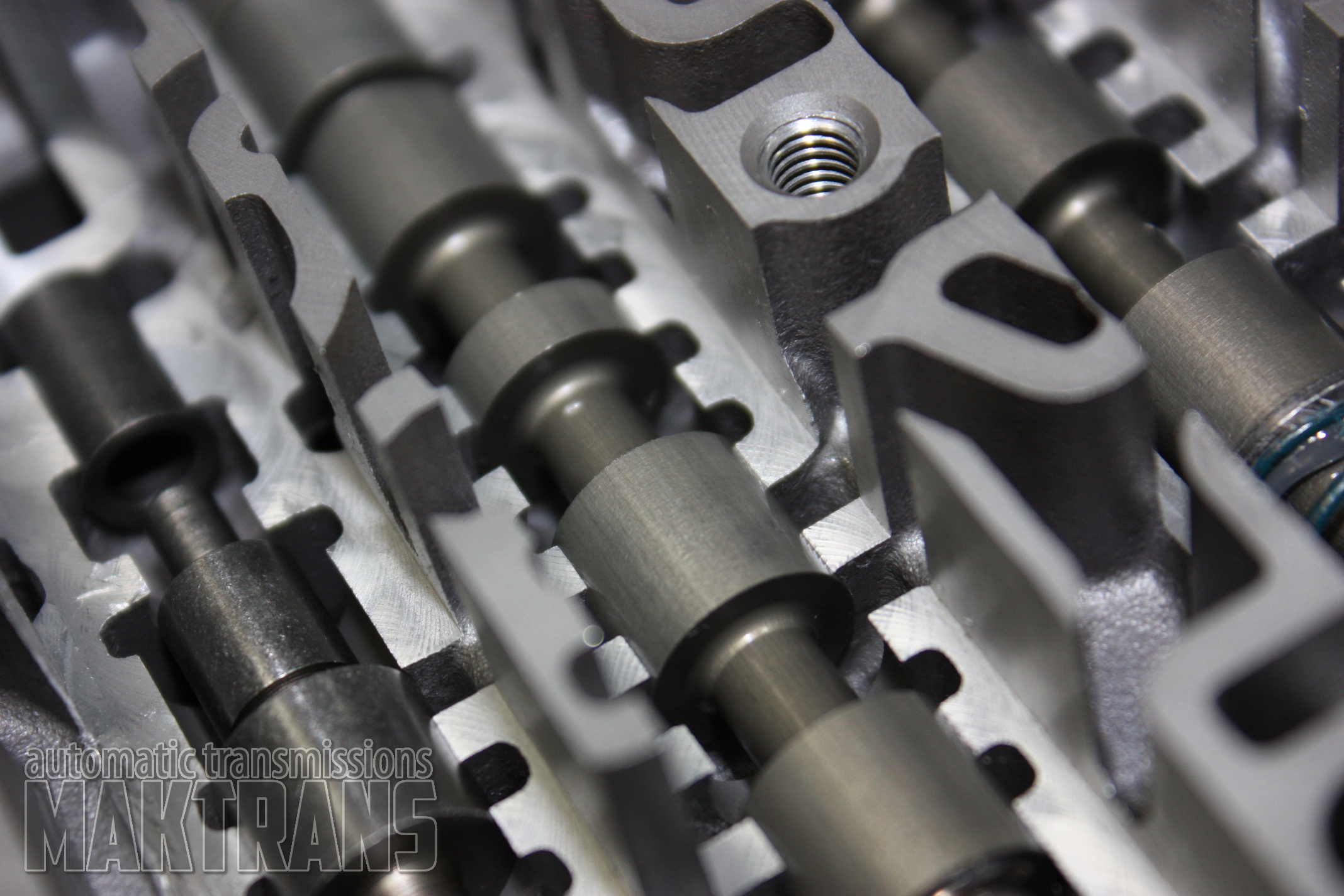

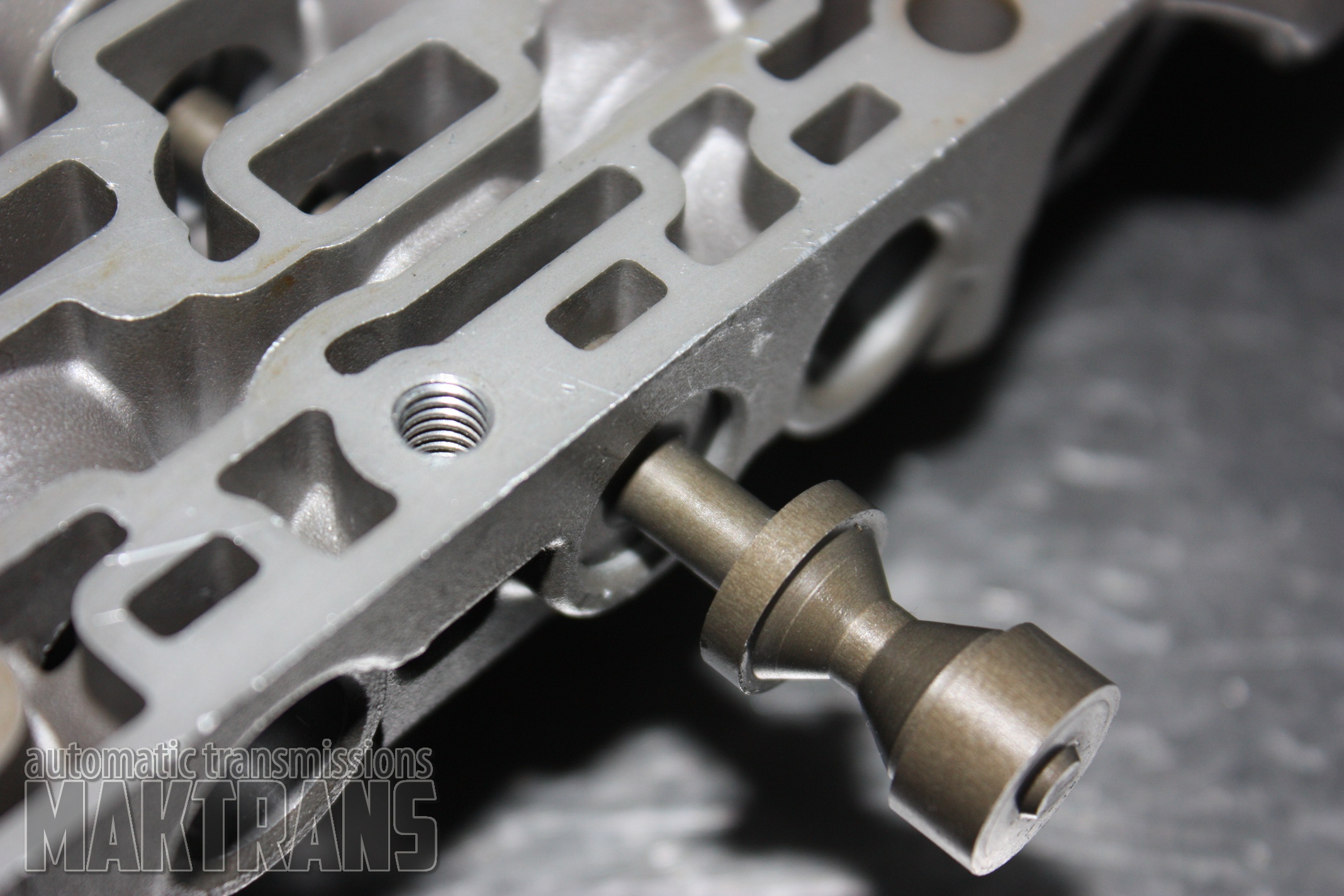

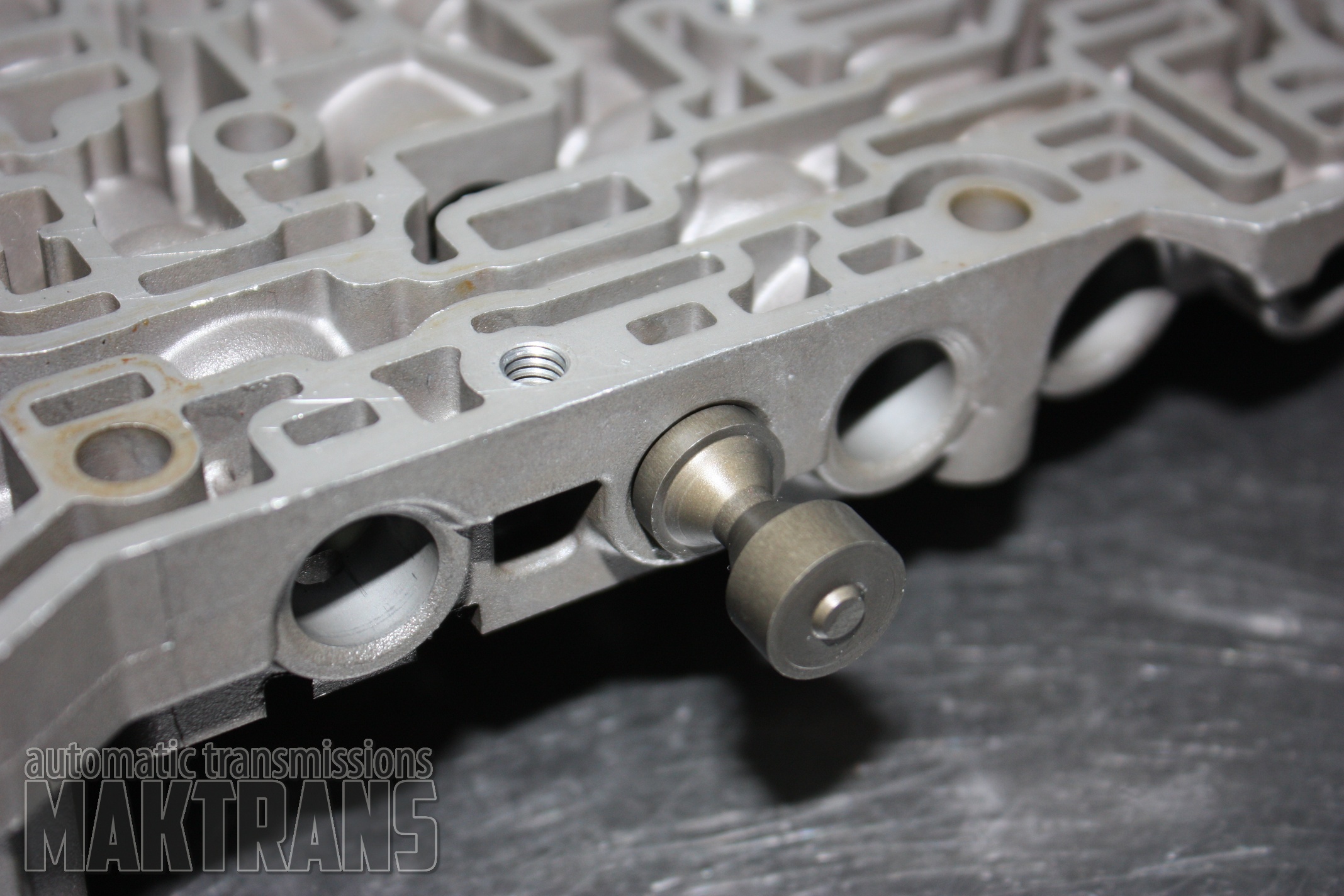

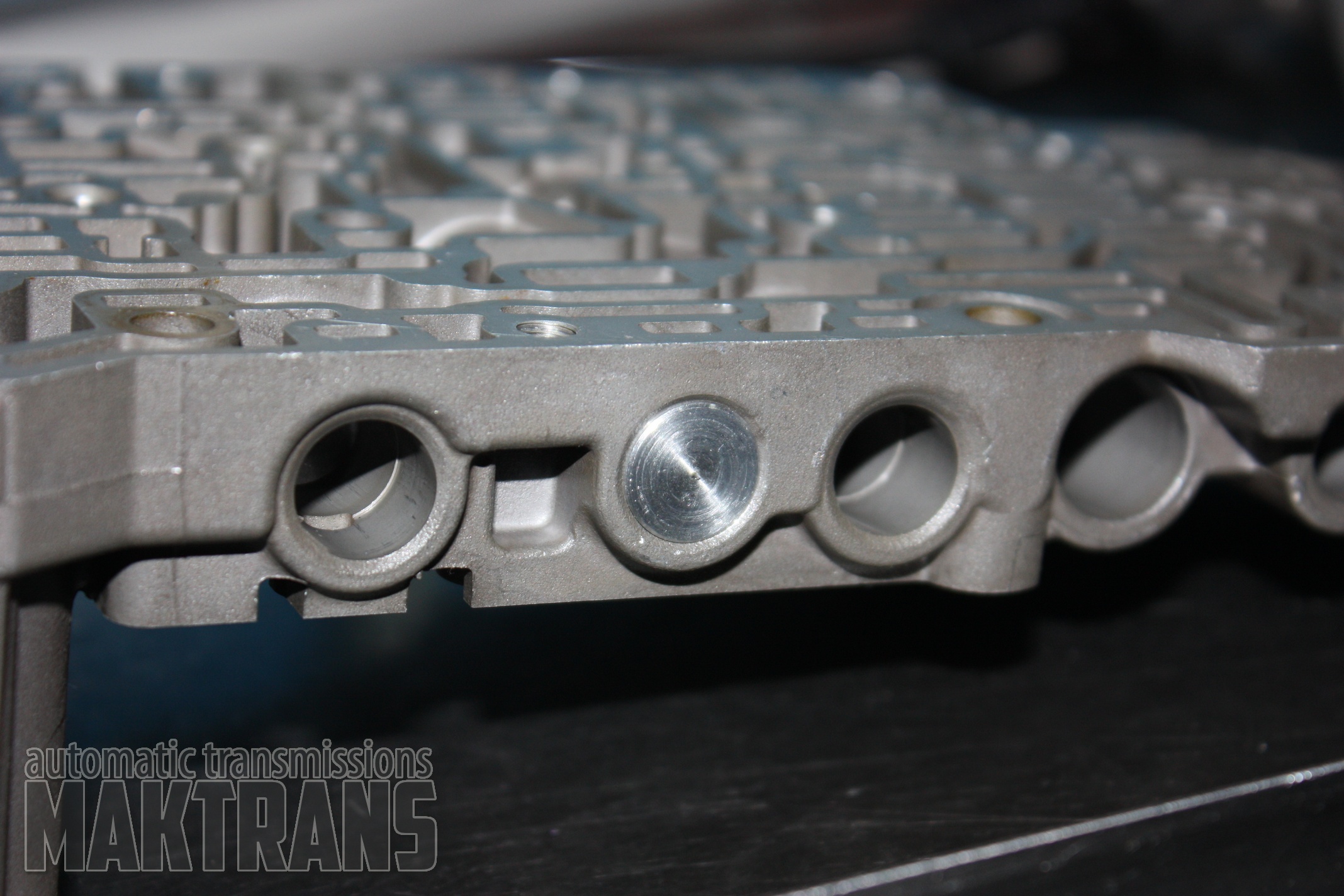

Immediately we are looking at the known weak places, in the case of U150, this is the modulator valve zone (on the left) and the zone of the secondary pressure plunger (right) - the wear is visible.

|

|

Remember, the wear of the channel as in the photo above - is critical, the valve will not work. But vacuum diagnostics theoretically can show ideal results, therefore each plunger is checked by hands for jamming in the channel, it always needs to be checked!

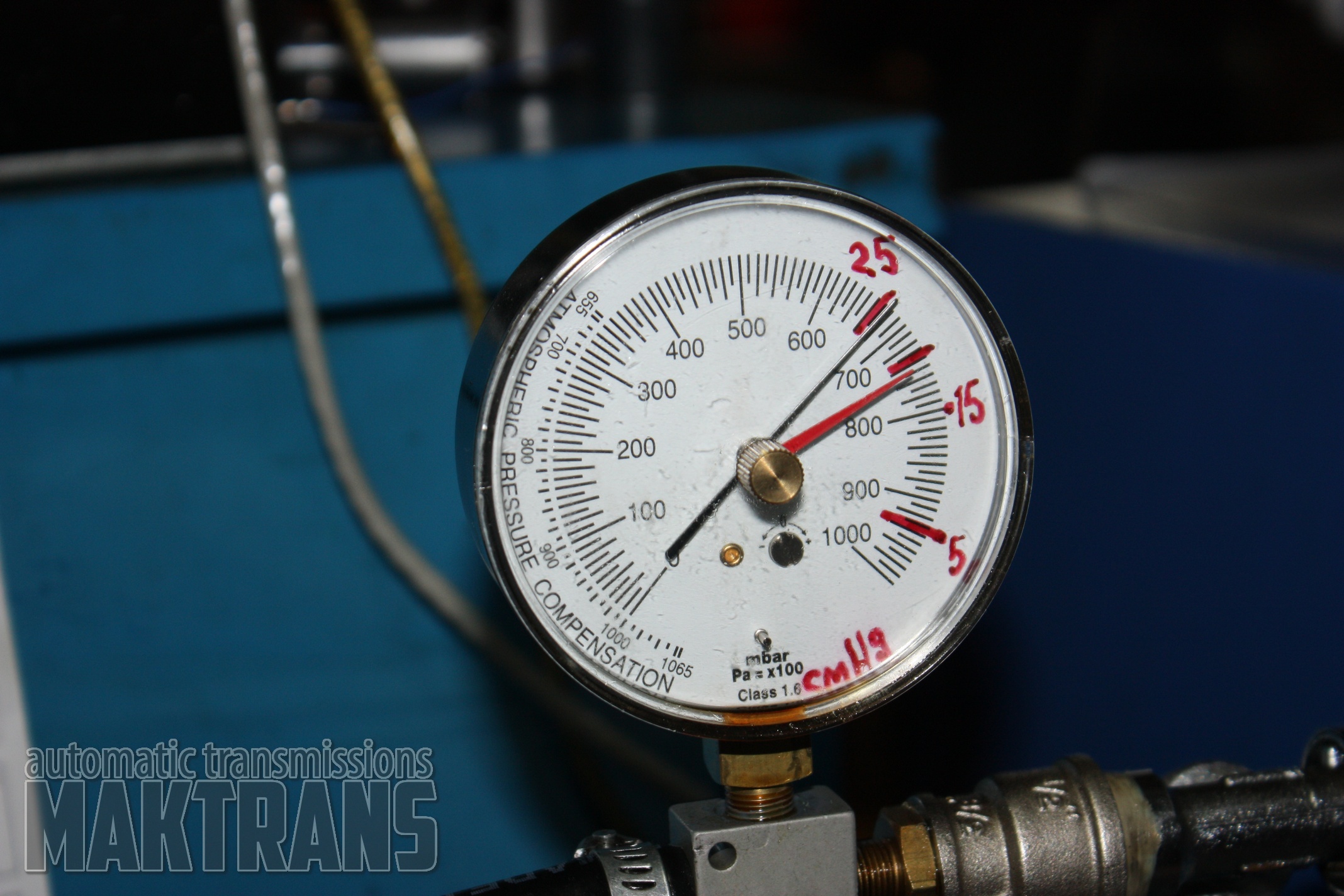

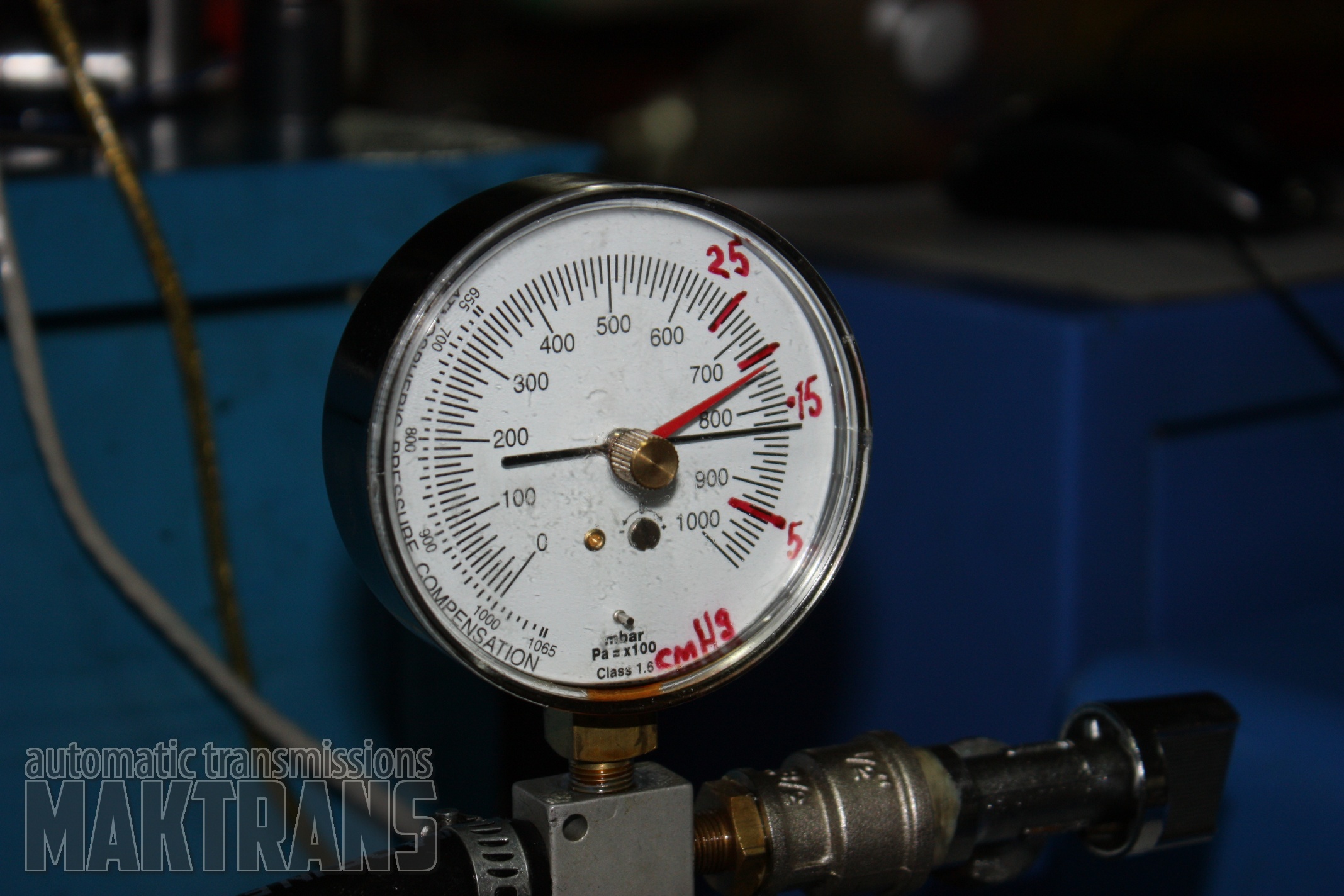

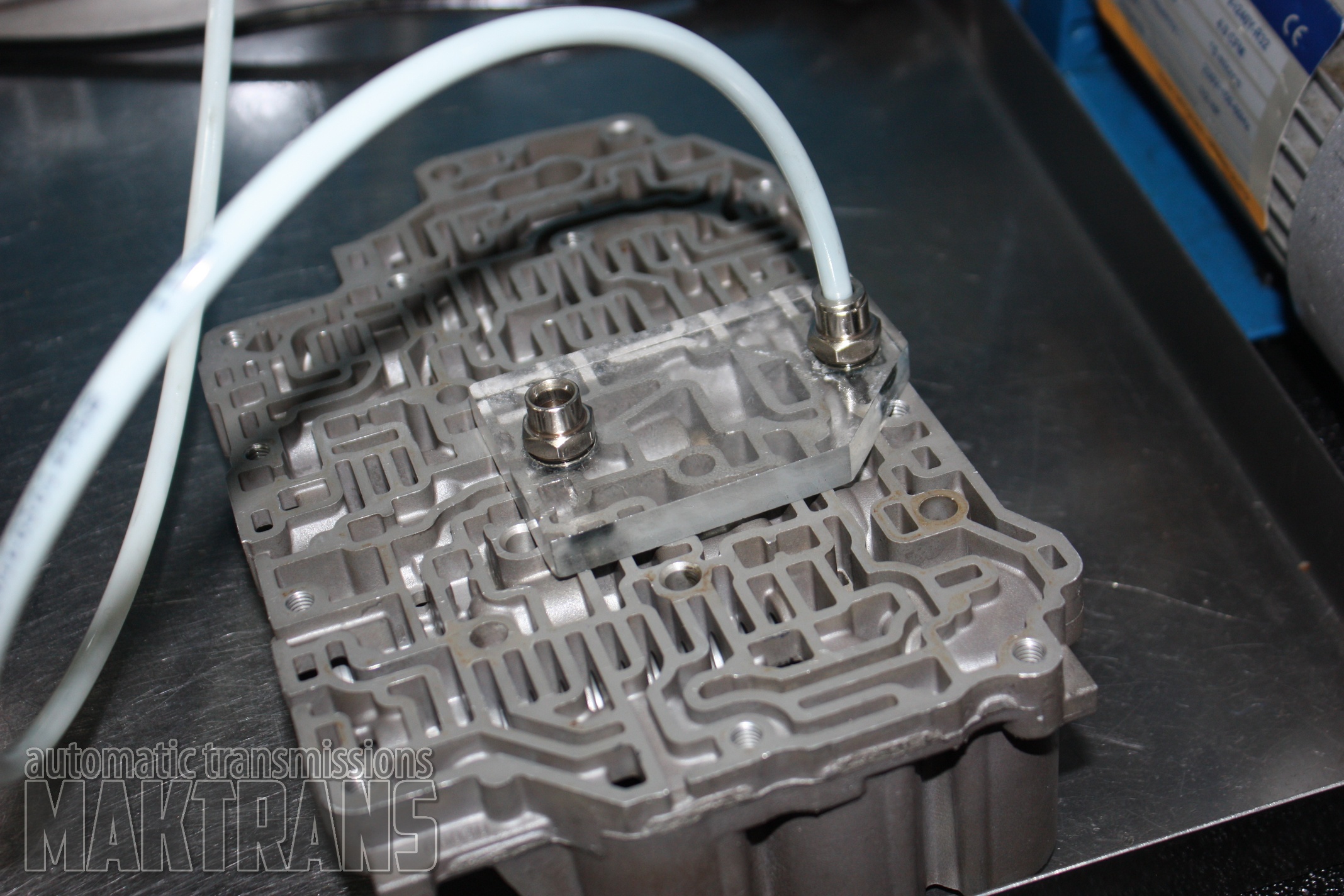

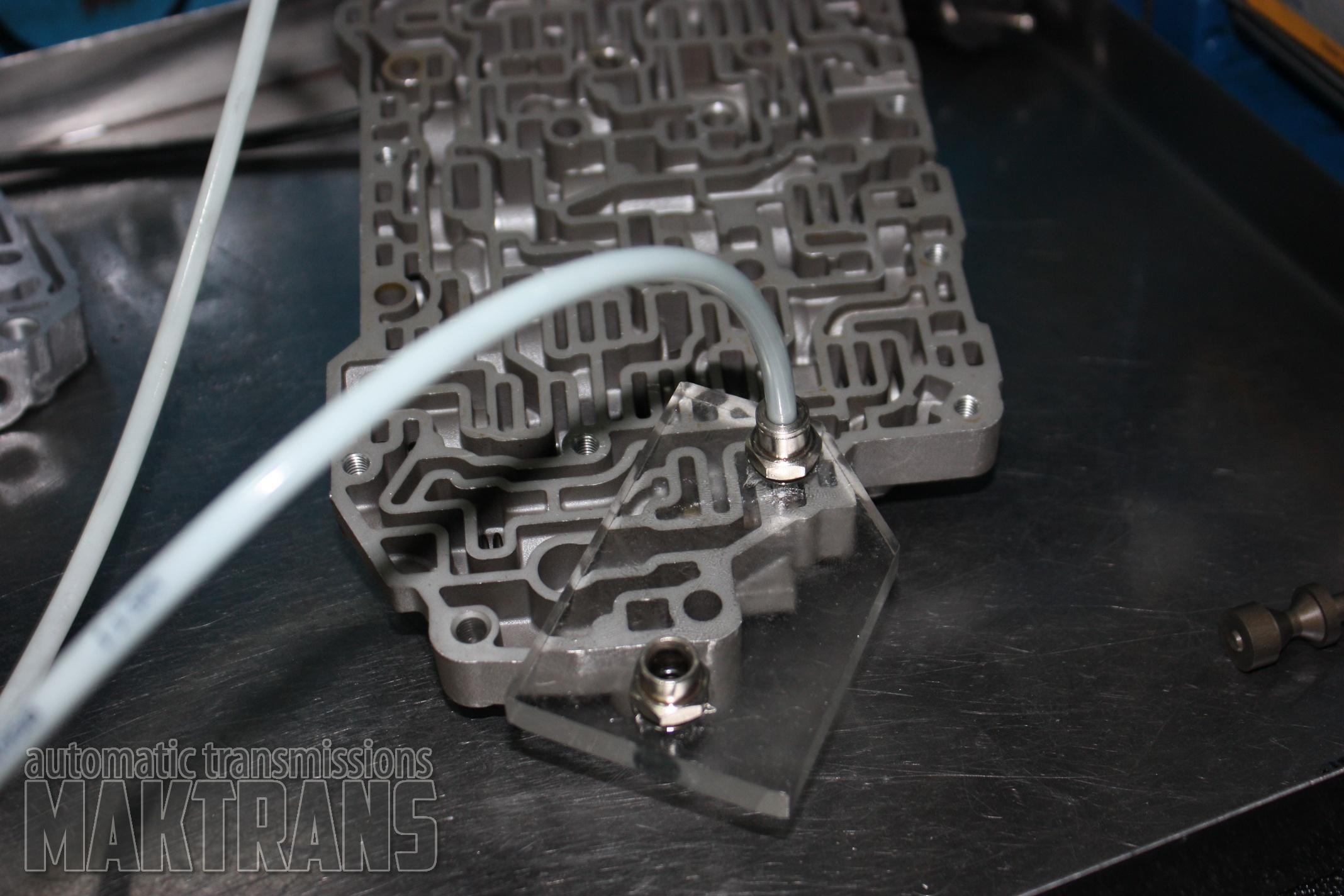

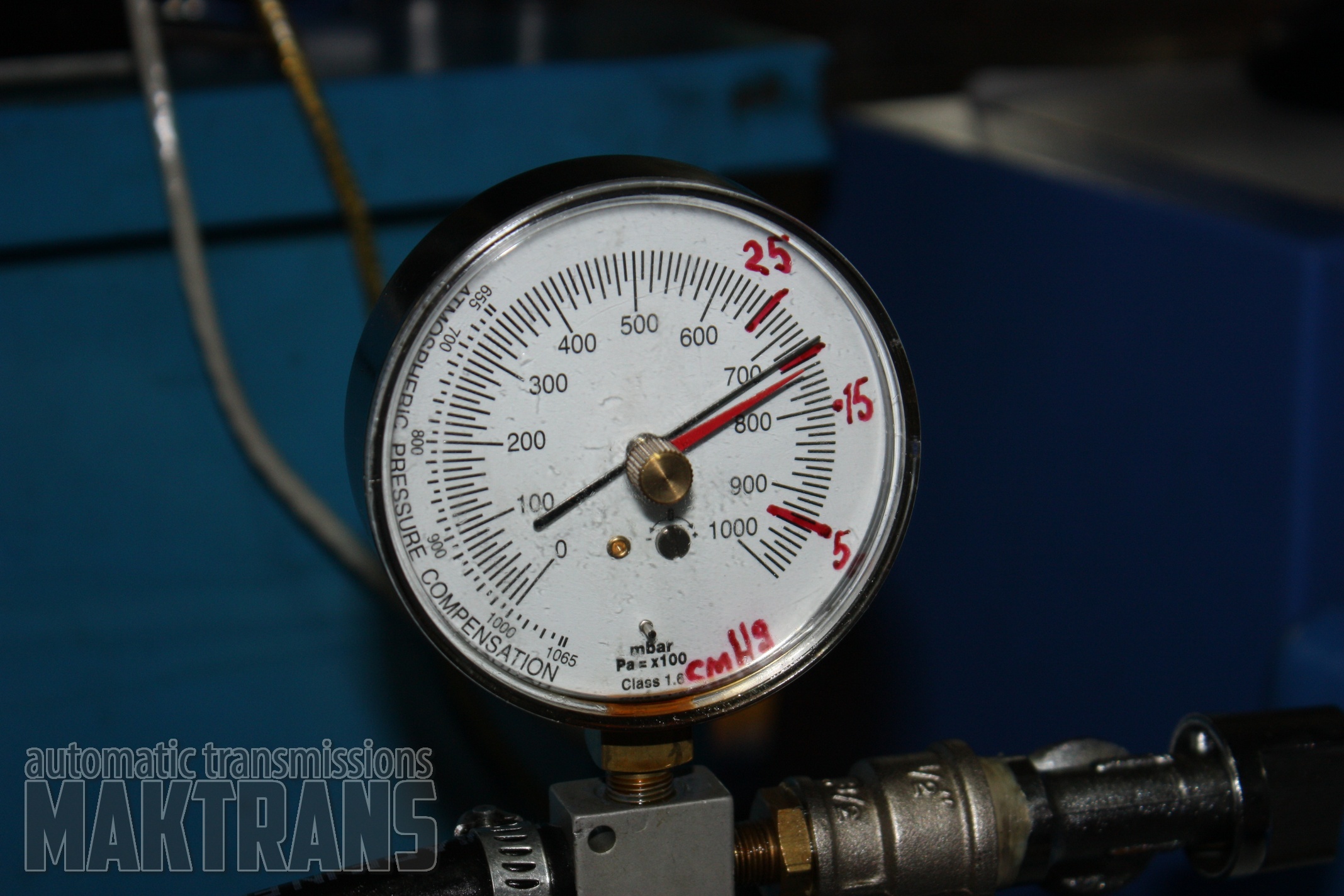

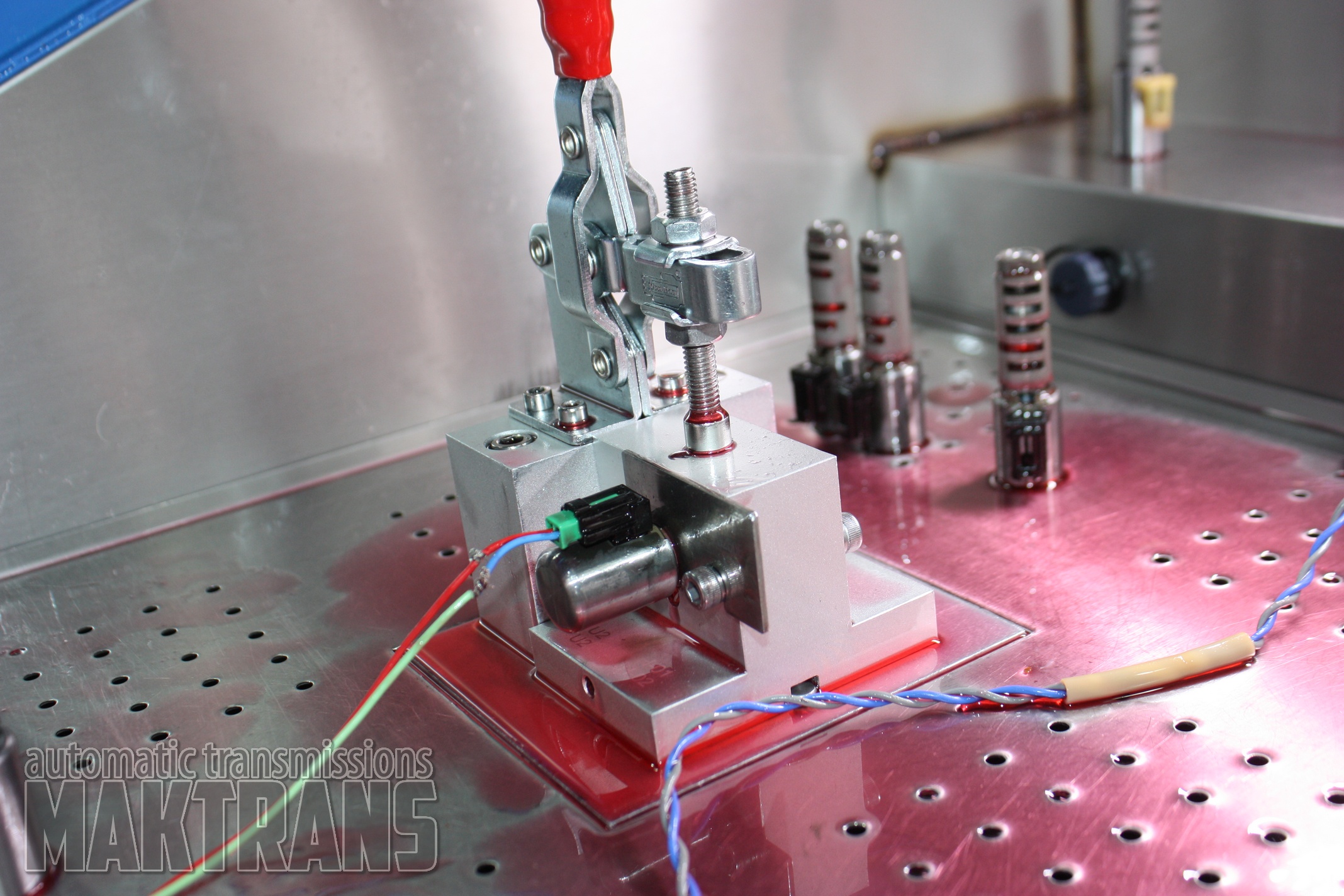

We begin vacuuming. We use vacuum testers of our own production, it is for sale.

|

|

|

The vacuum test also indicates problems with the modulator and plunger of the secondary pressure, we will replace them. The rest repair valves produced by "Maktrance" for U150 / U250 valvebodies can be viewed here.

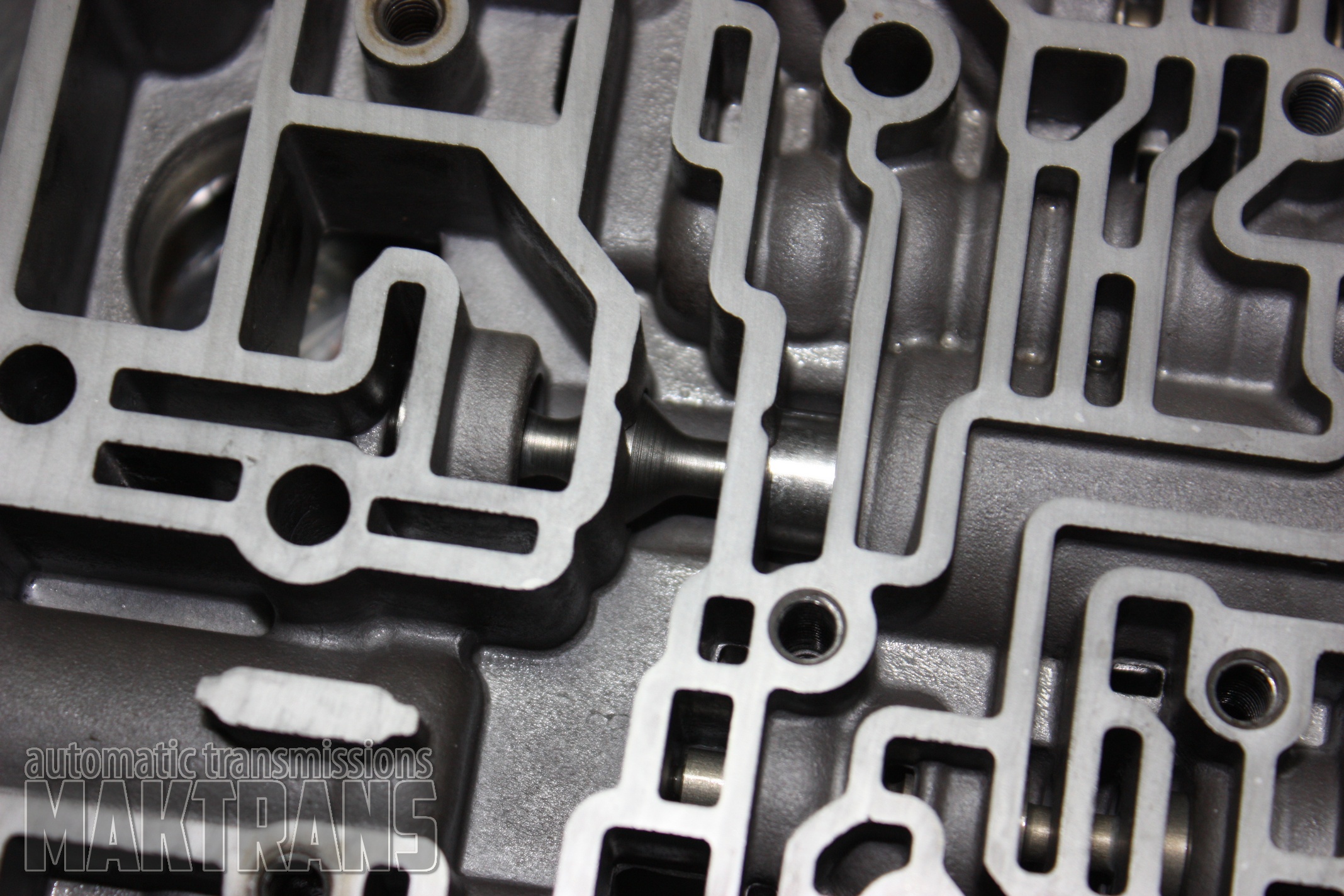

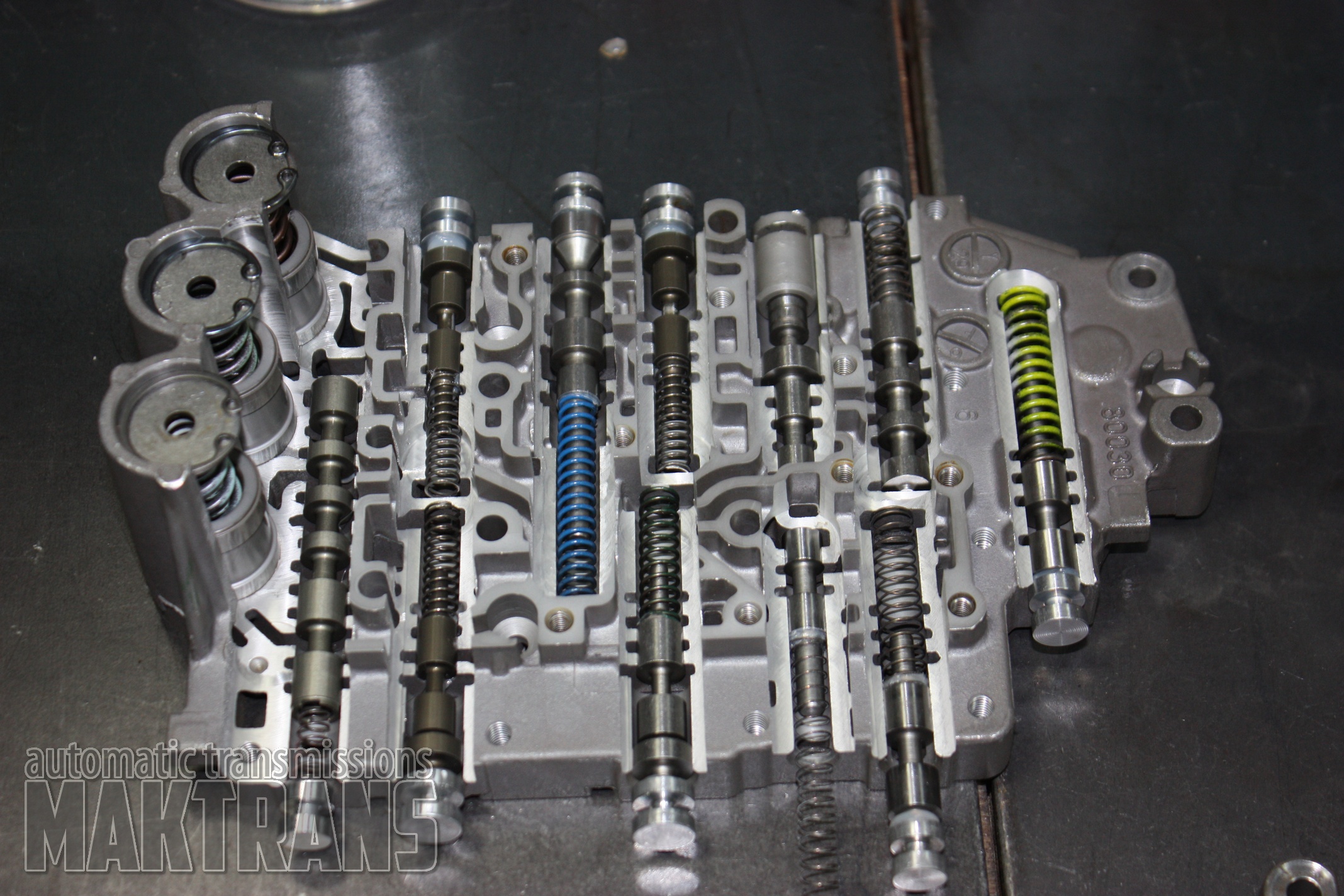

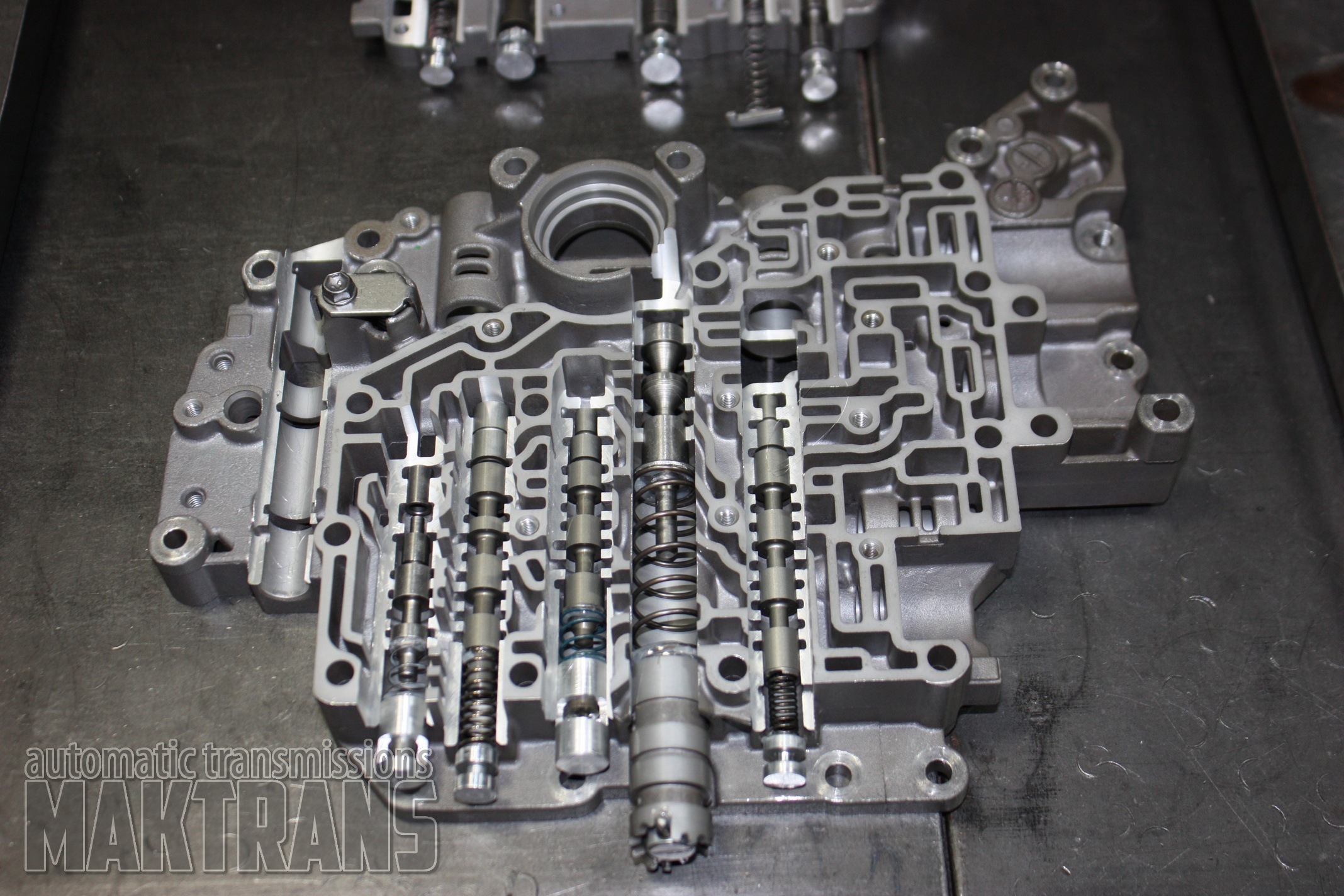

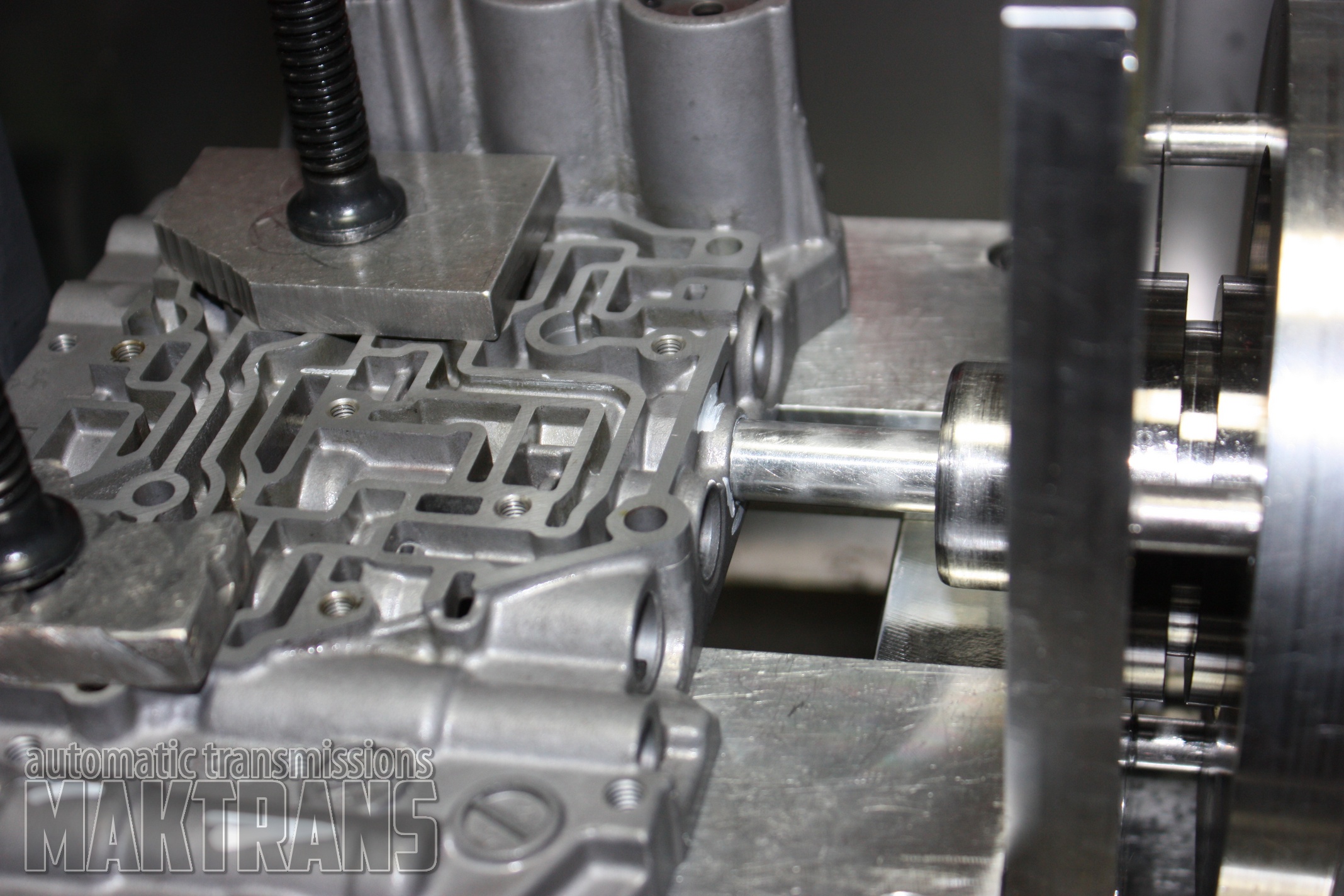

First, you need to completely disassemble hydraulic plates and remove absolutely all the parts (valves, plugs, stoppers, springs, balls). We advise you to decompose them in the order in which they were extracted. If you encounter problems when assembling - use the photo below, this is cut U150, valvebody so we use these photos to facilitate the assembly process.

|

|

|

|

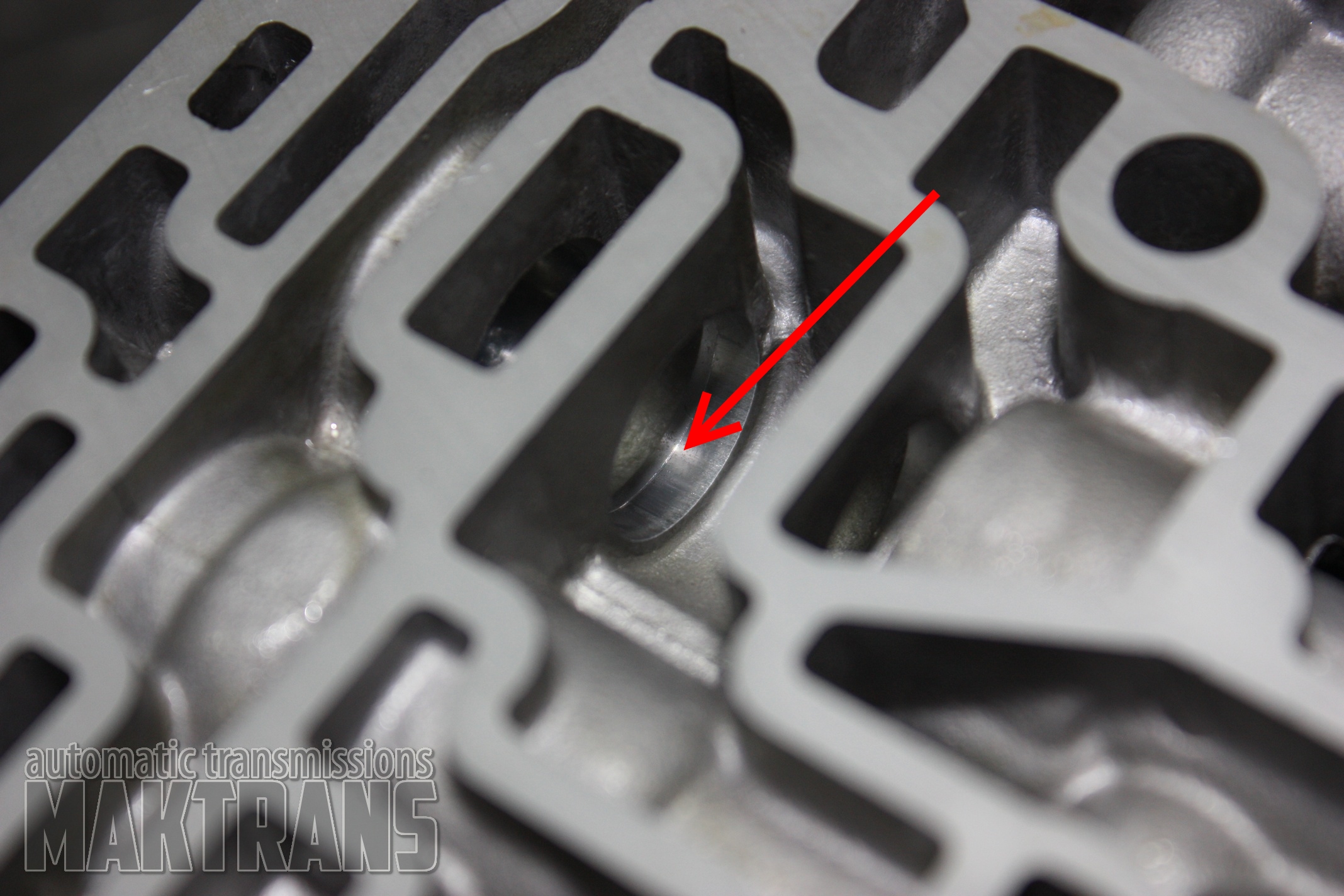

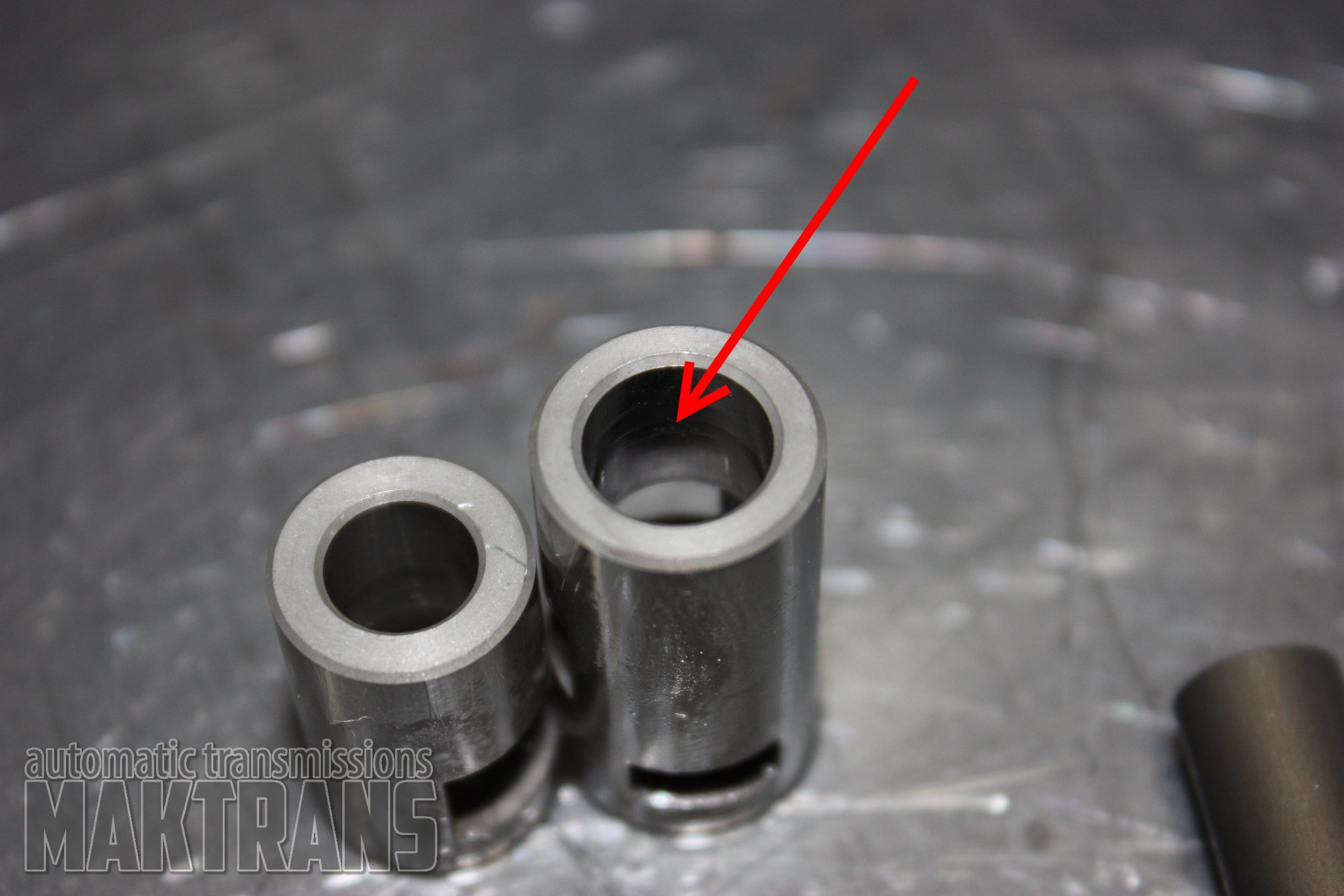

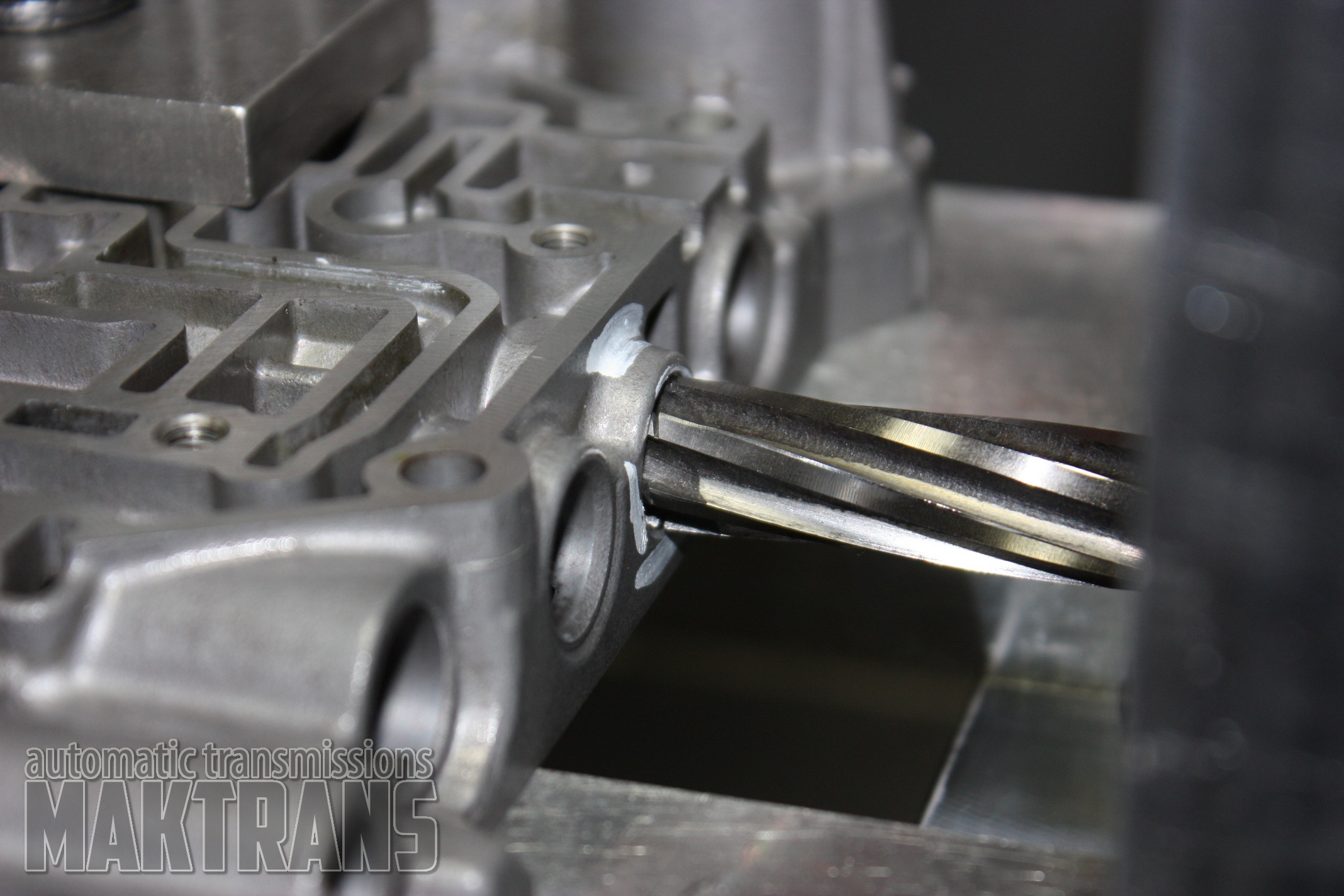

At the stage of disassembly, we find another popular disease of Toyoto valvebodies, it is a booster valve. The wearout on the inner wall is visible. We replace this valve for a new one, of our own production.

|

|

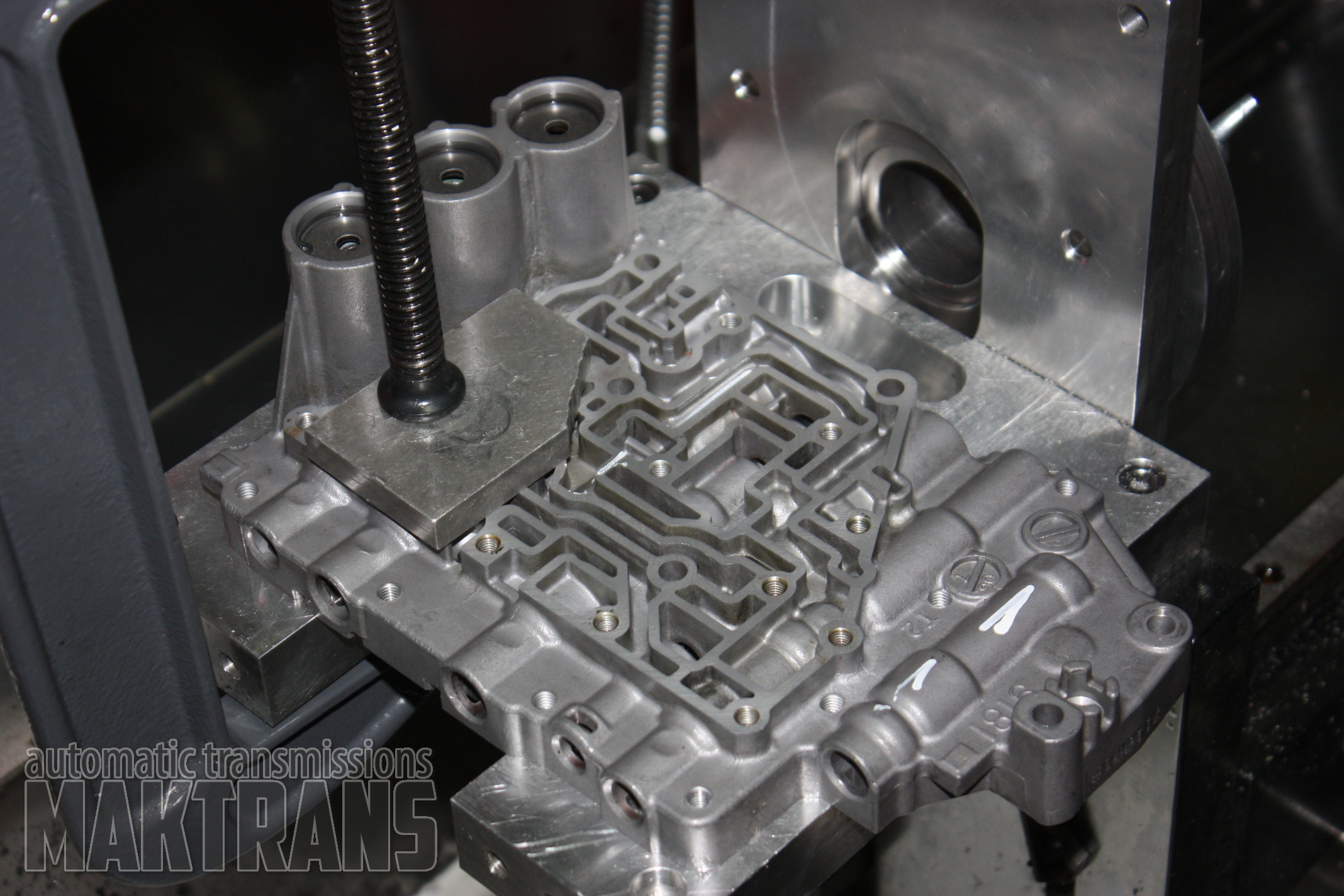

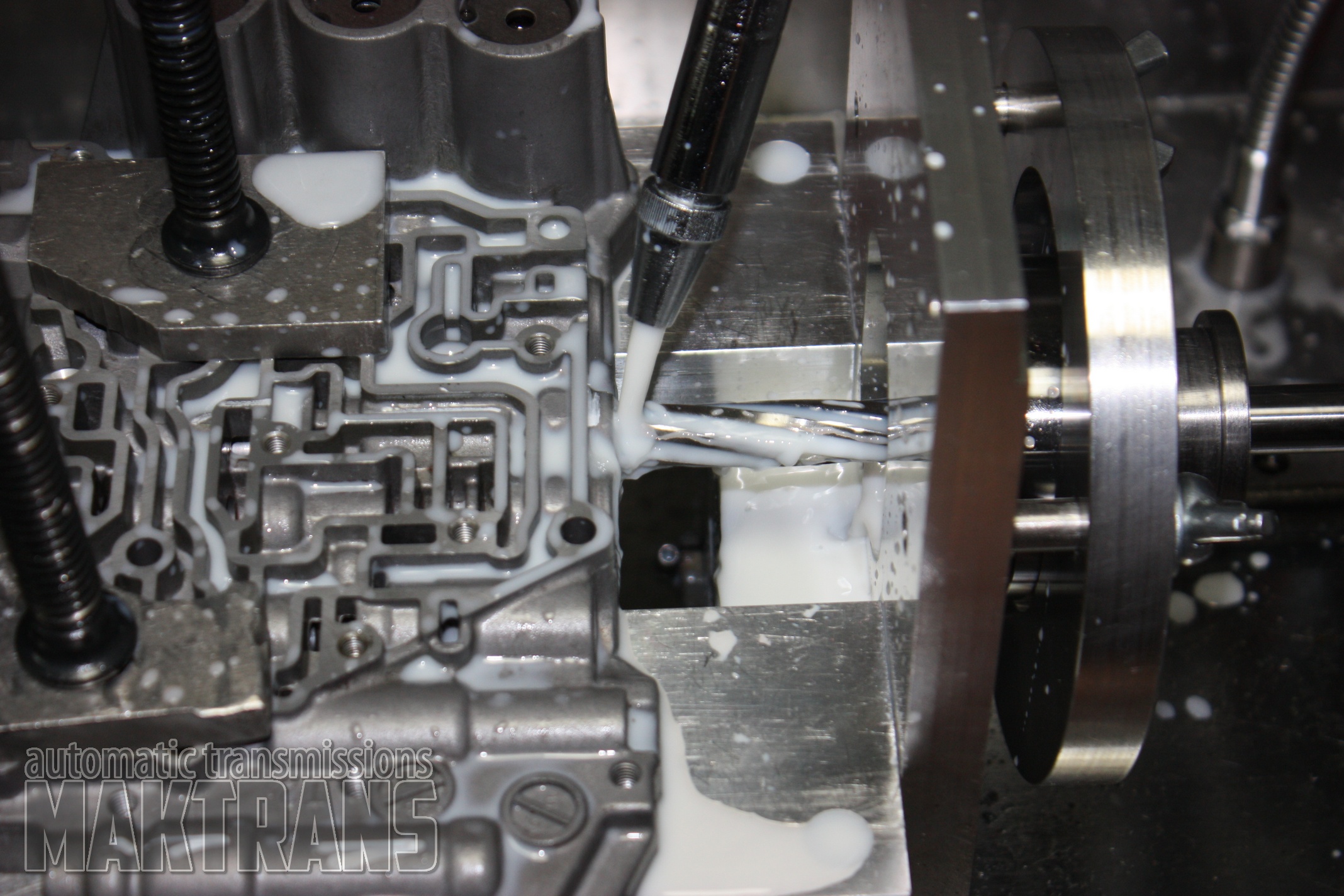

We pass to the machine for drilling holes, correctly set the plate with the help of the guide, the guide and the bushing come complete with each reamer.

|

|

|

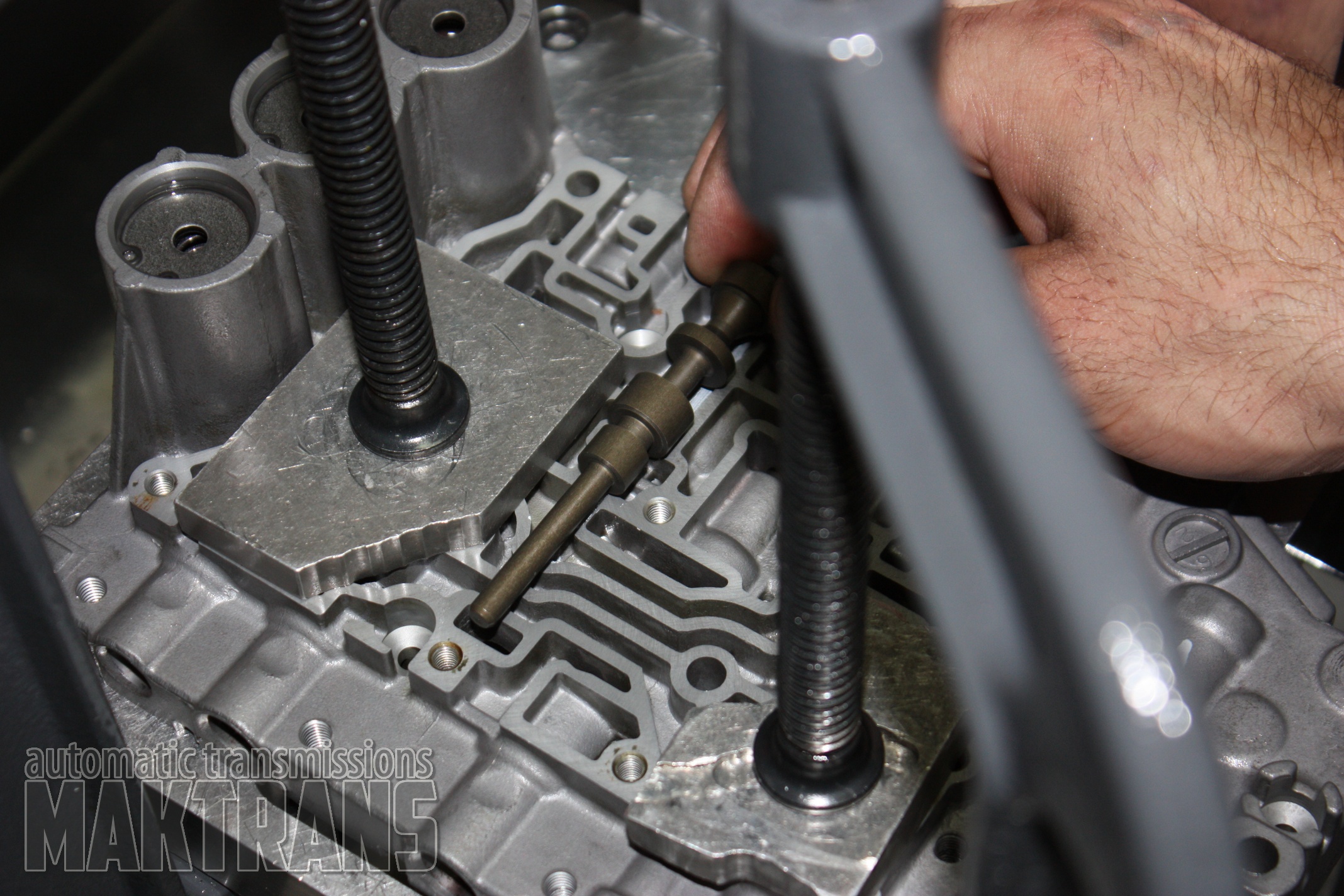

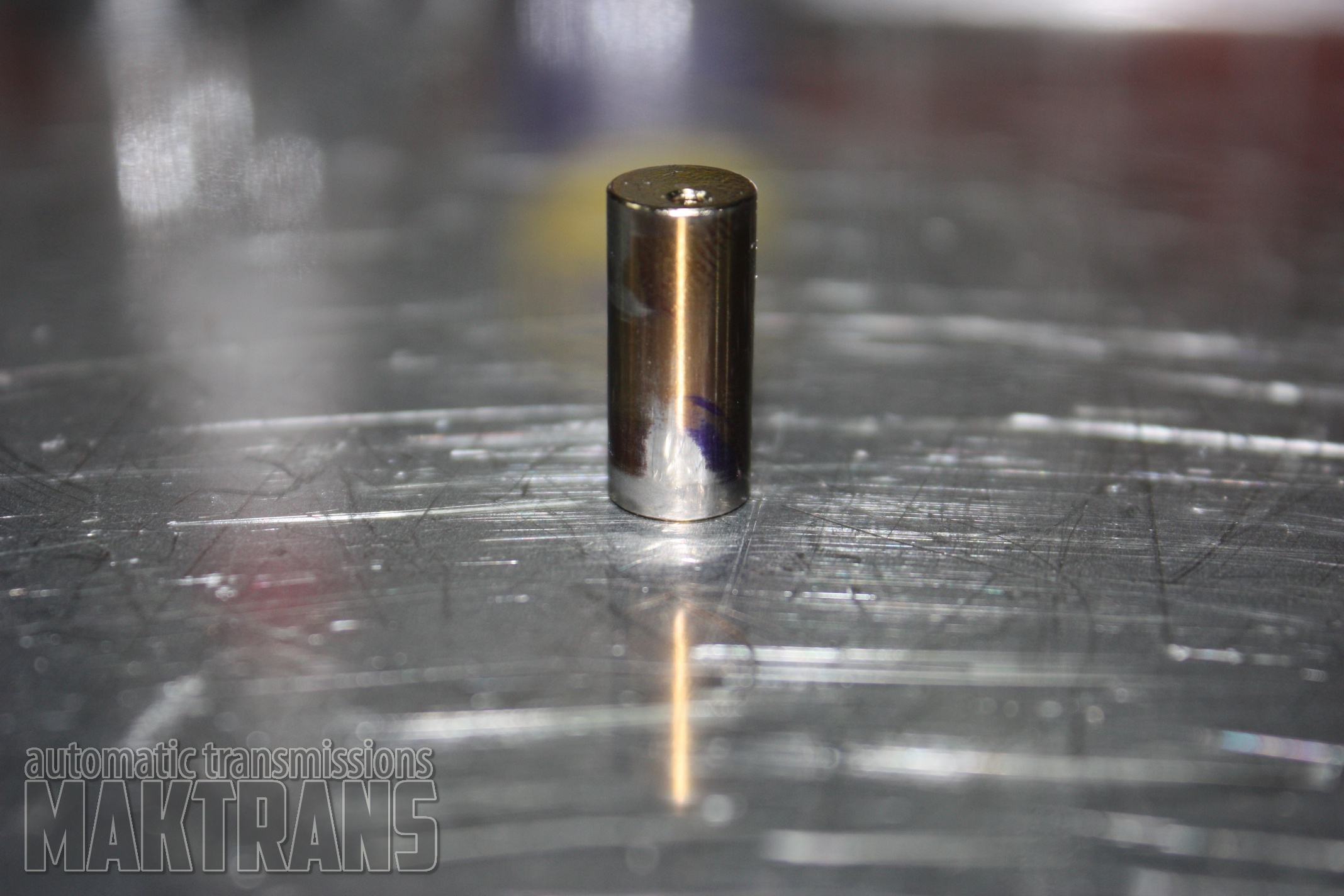

When the opening for a complicated valve having several diameters is being reamed, you need to determine the distance that we will go through with a reamer very carefully , the easiest way to do it is as follows, take the repair valve and measure:

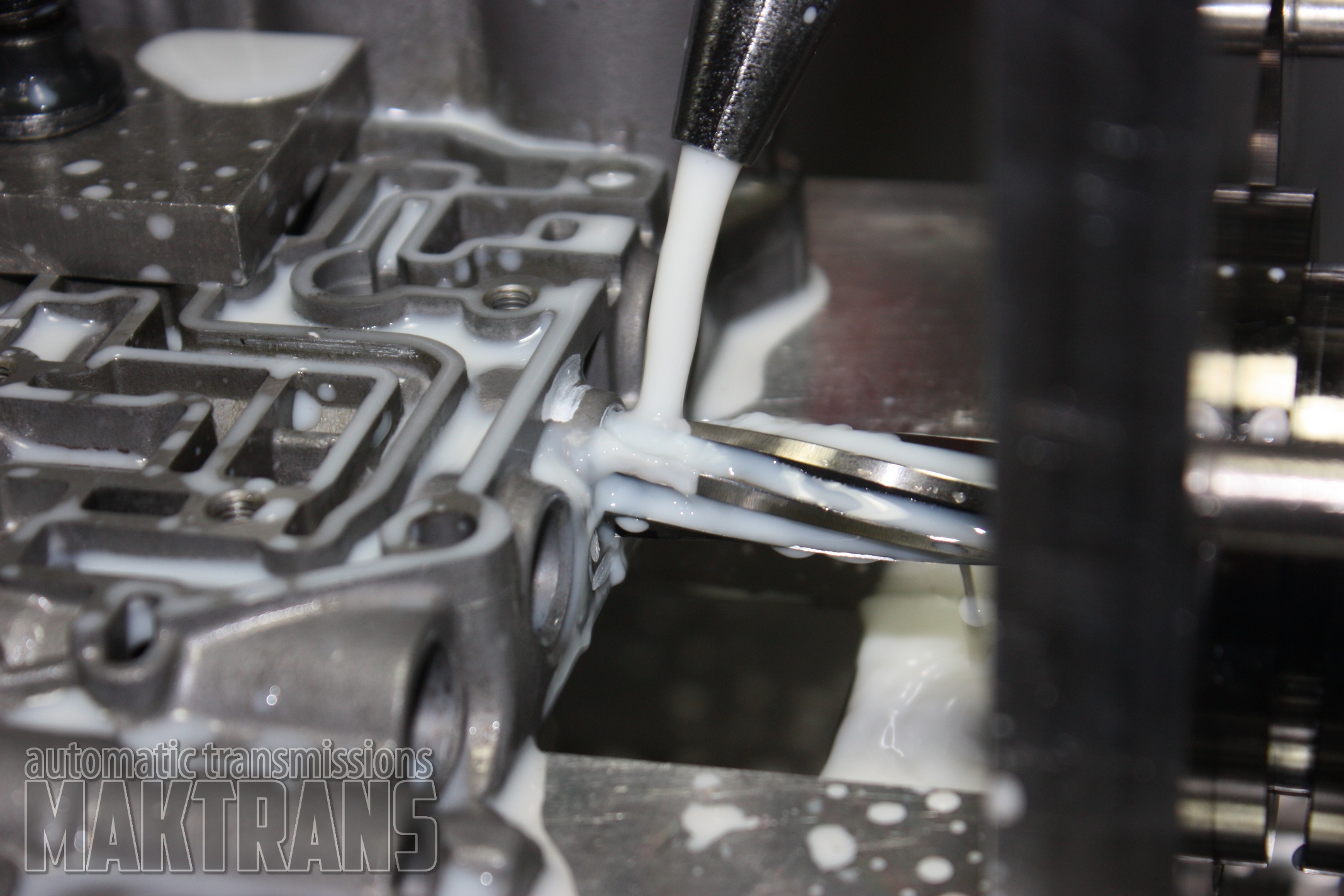

Turn on cooling and cut

|

|

|

Put oversized valve and plug

|

|

|

Again it is necessary to use a vacuum tester to make sure that everything went fine.

|

|

|

The installed secondary pressure repair valve has passed the test, in the same way we repair the opening of the modulator valve. In general, the process of reaming the holes is not difficult, if you observe several points - to ensure good cooling, do not drill at high speeds and control the reamer pressing, it is not necessary to press strongly on it. That's all about it, now we pass to the solenoids.

Solenoids are the source of approximately 80% of all malfunctions in the U150 valve body , their restoration or replacement is always an integral part of the repair. The specialists of "Maktrans" company offer 3 options for solving the problem:

Replacing the solenoid with a new one is the simplest and most expensive option, but not the best one. The resource of the solenoid is the same as that of the factory one, which means that after passing 100 thousand kilometers everything can happen again.

Regeneration - we change the solenoid plunger to a plunger of our own production, which has a better and more resistant to mechanical damage anodized coating.

The third option - the two most heavily loaded solenoids can be replaced by solenoids from a completely different Aisin Warner transmission, they are structurally better (the inductor is larger, hence the return spring of the plunger is also more powerful, such a solenoid will be less affected by the dirty oil)

U150 has 7 solenoids, 3 of which are ON / OFF and they almost never break (pictured left), and 4 PWM solenoids (pictured right), with which there are problems.

|

|

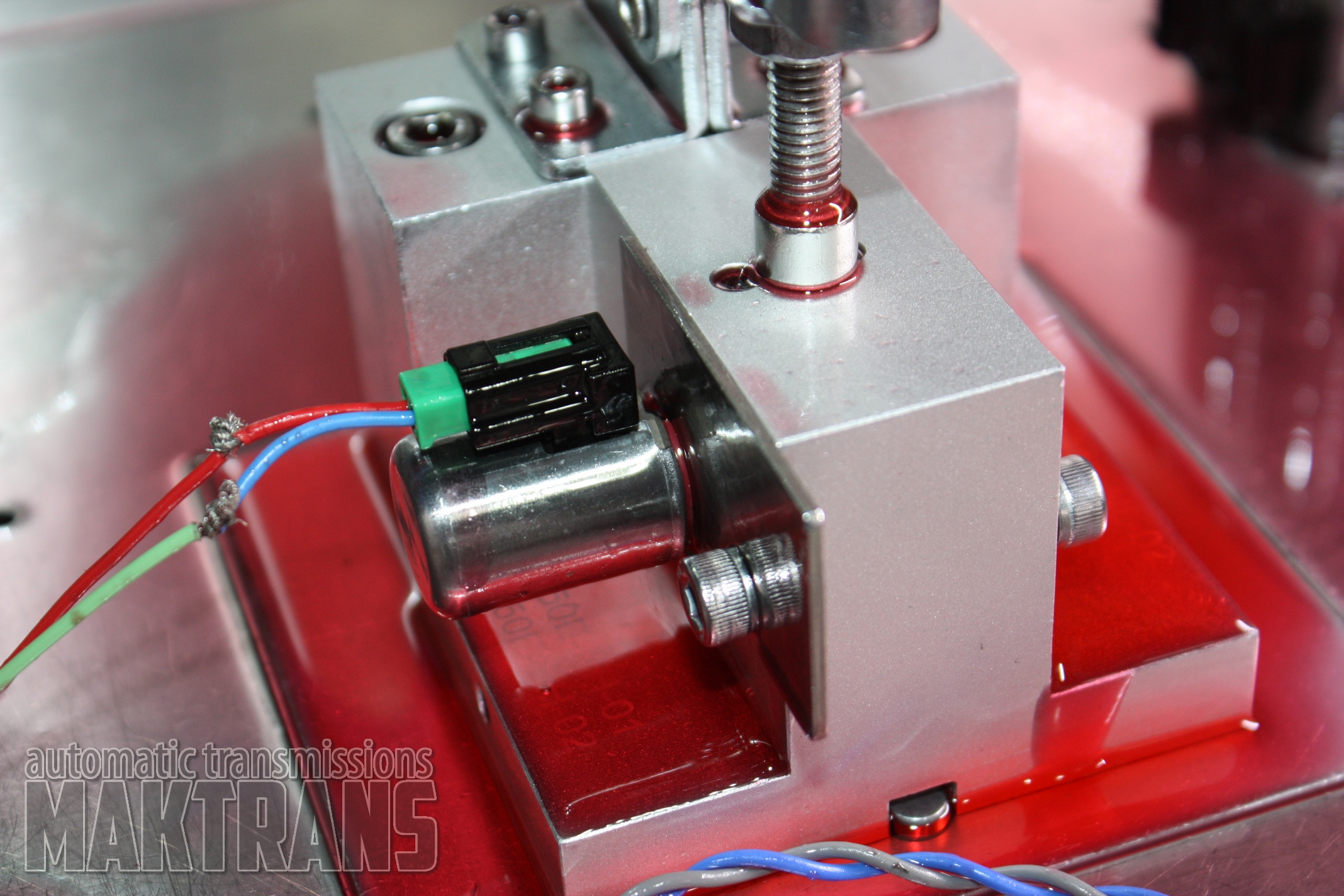

We install the solenoid in the stand and begin testing.

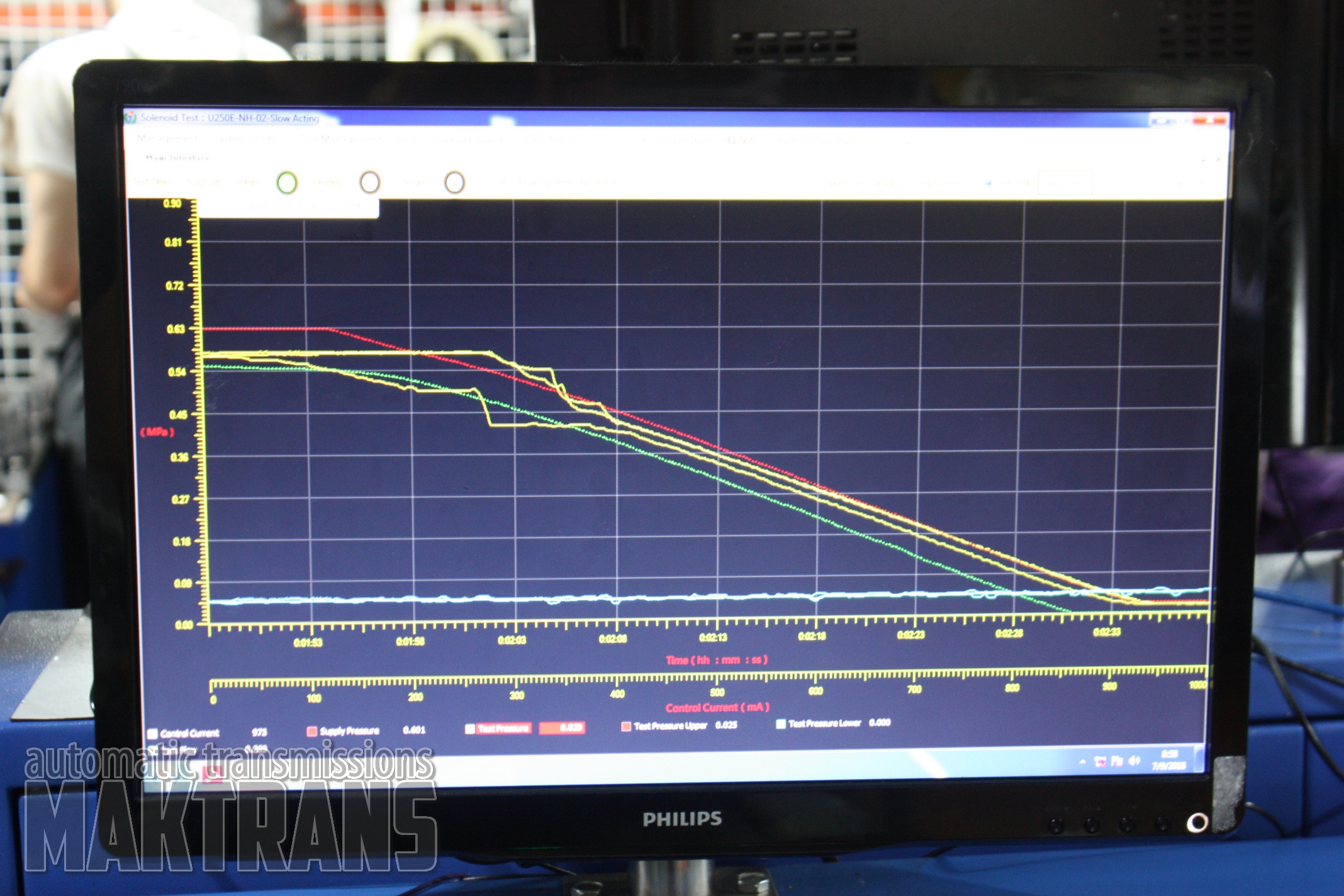

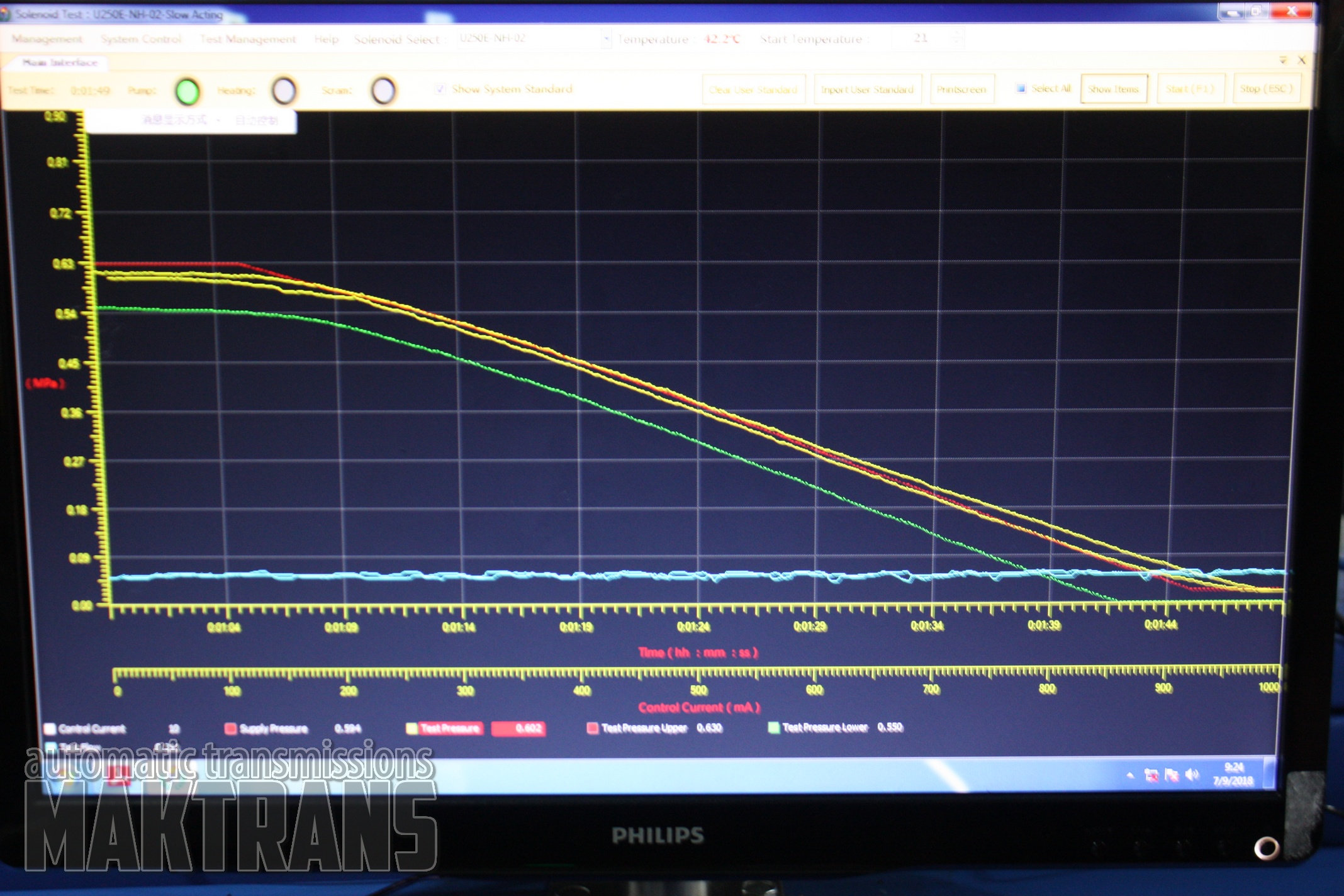

Our equipment allows real-time scheduling of solenoids simulating real box operation and different temperature modes. "Steps" on the graph below show that the plunger in the nozzle of the solenoid jams when it opens.

We will analyze and see why this happens. For dismantling, a tool is used that allows you to fix the case and use a special "knife" to open it.

|

|

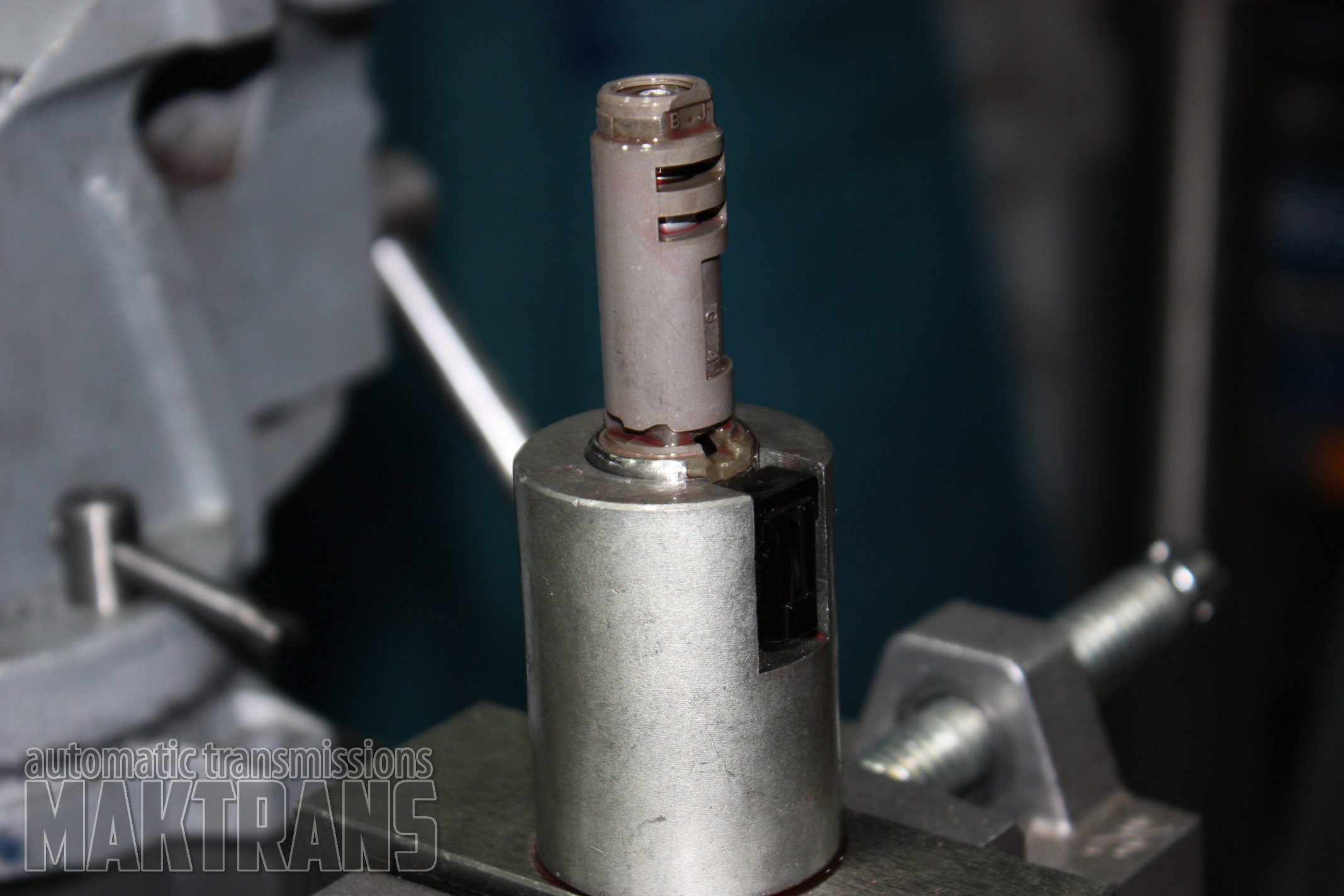

Disassembled solenoid

|

|

|

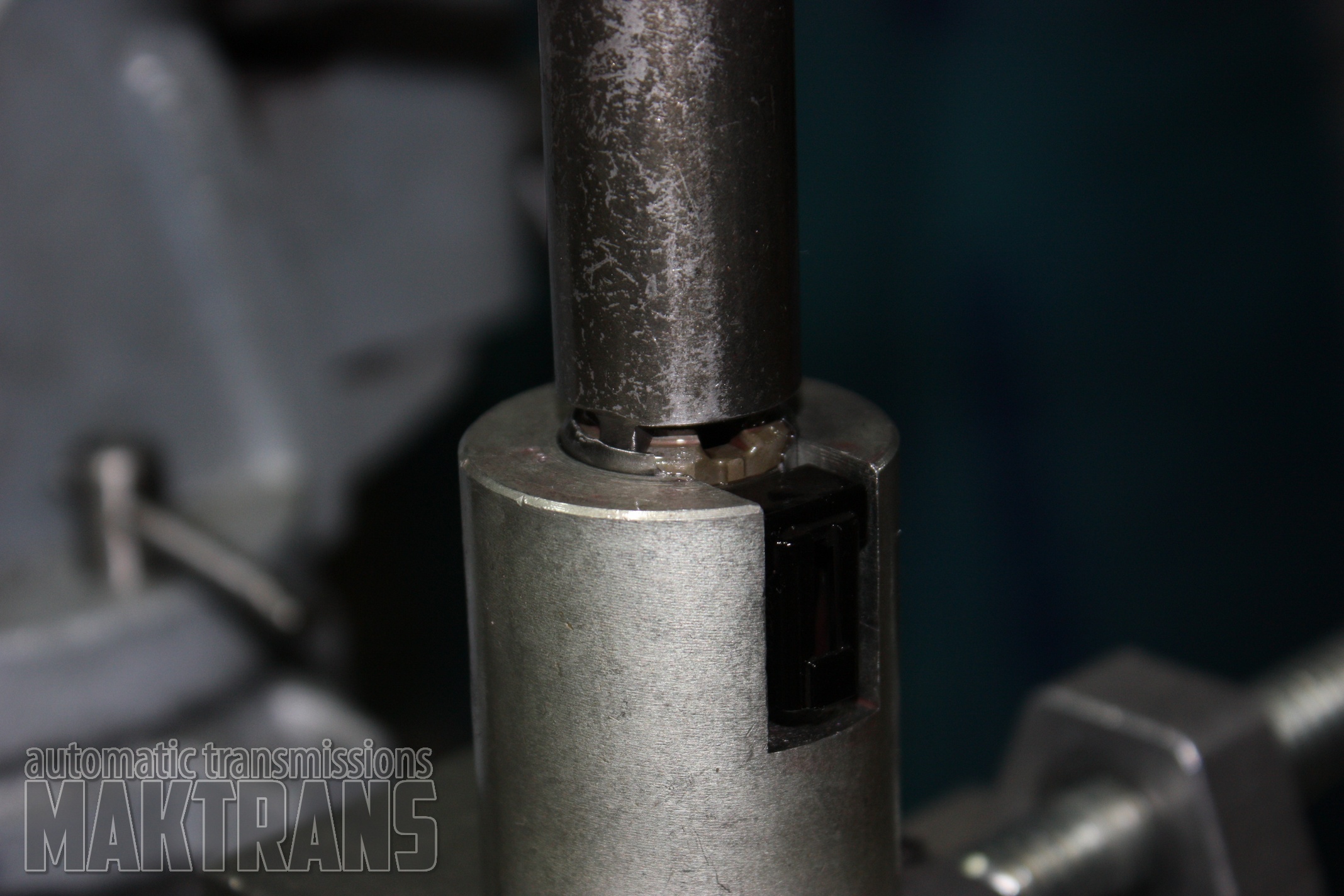

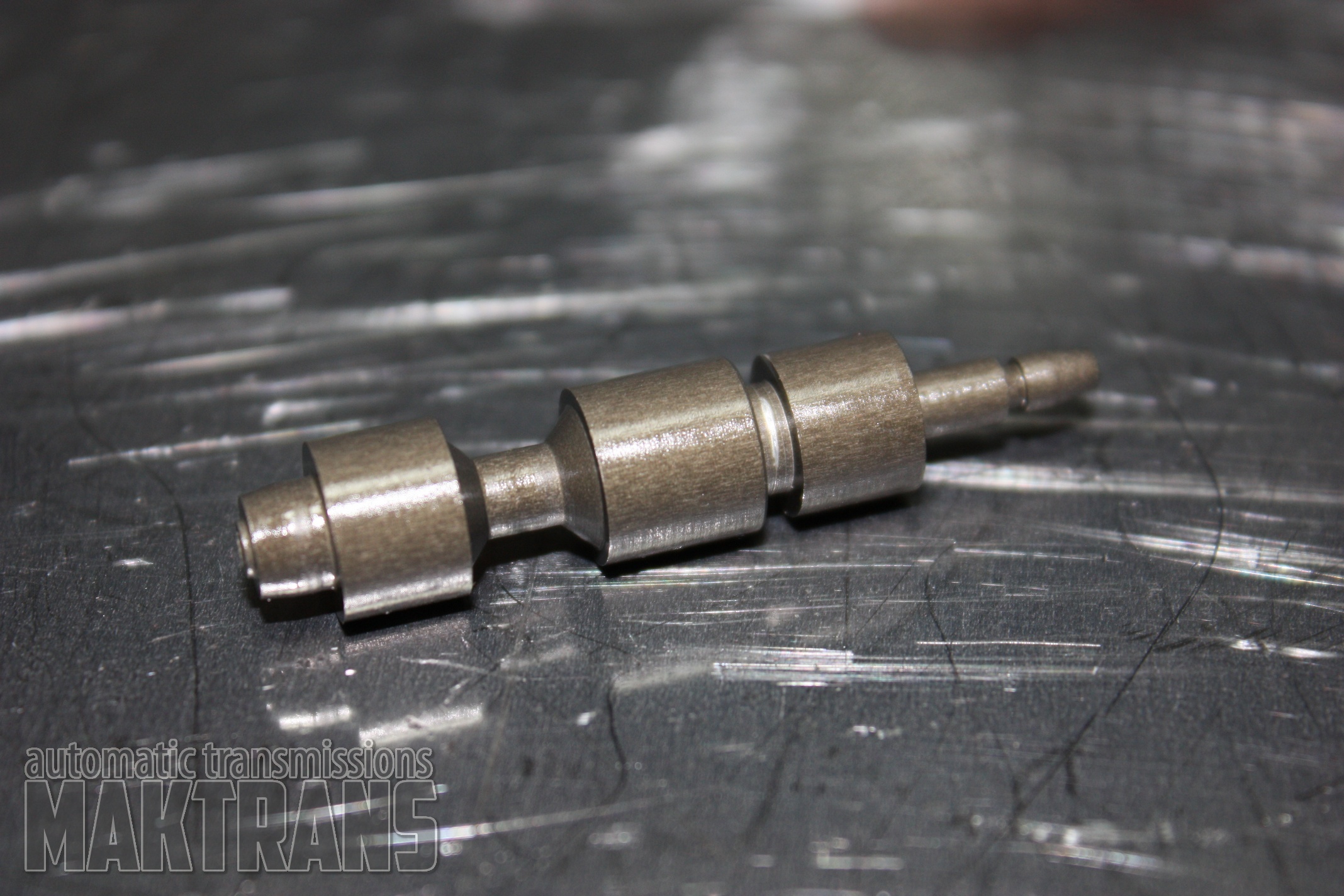

We remove the plunger pusher, the cover in the lower part is worn out, it will be skewed in the coil and the movement will not be smooth, but jerky. The pusher can simply be polished by removing the factory unstable cover and put back, it will work well. In the photo below the pusher is before / after polishing.

|

|

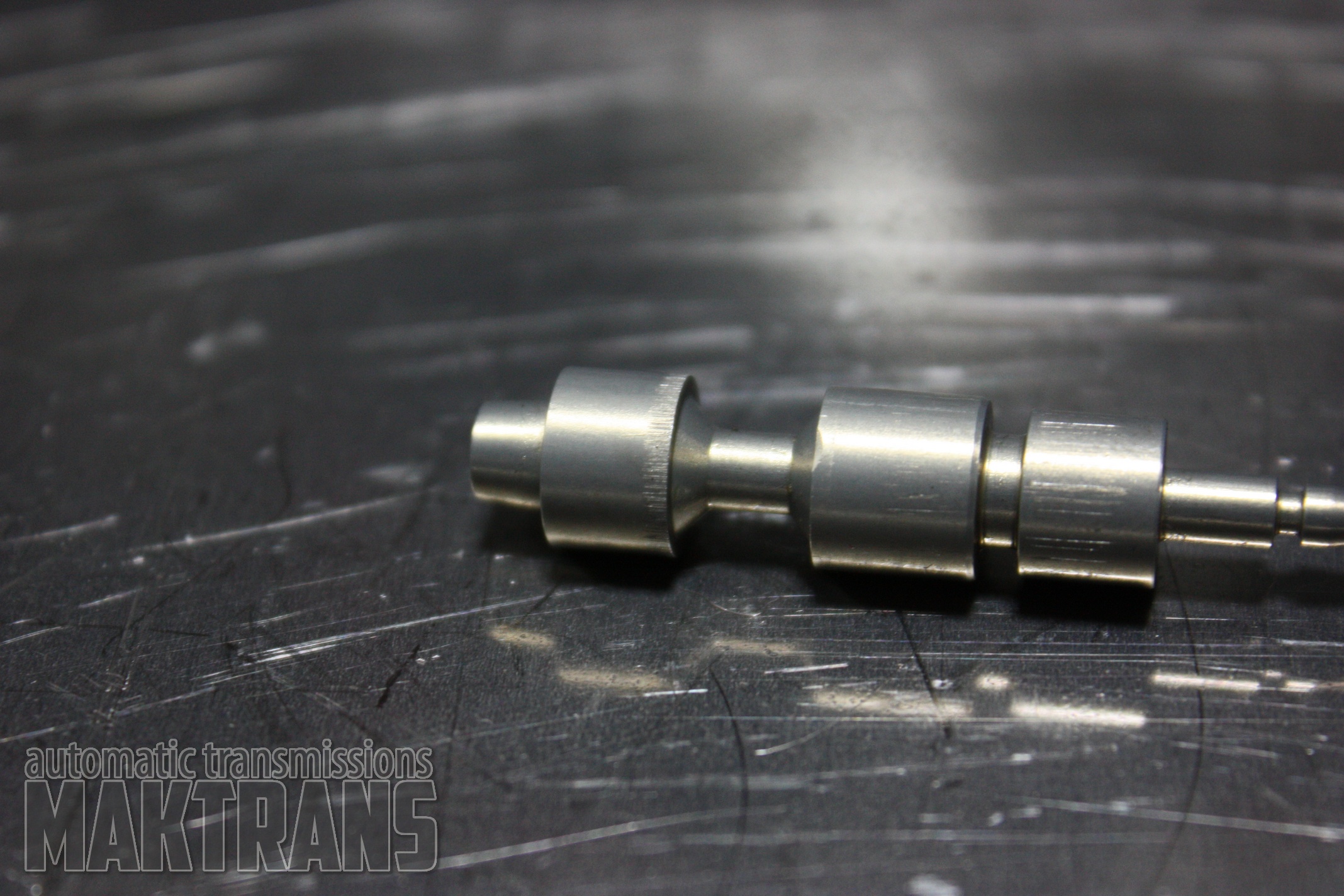

We disassemble the nose of the solenoid and get the culprit of all problems - plunger. Here are these scuffs and scratches and explain the chart that we saw when testing.

We take the plunger produced by "Maktrans" and install it. There is one nuance here, the plungers are not the same and they need to be selected according to the diameter, we have diameters of 8.18 mm, 8.26 mm and 8.32 mm for SL1 SL2 SL3 and 8.45 mm for SLT (EPC) solenoids.

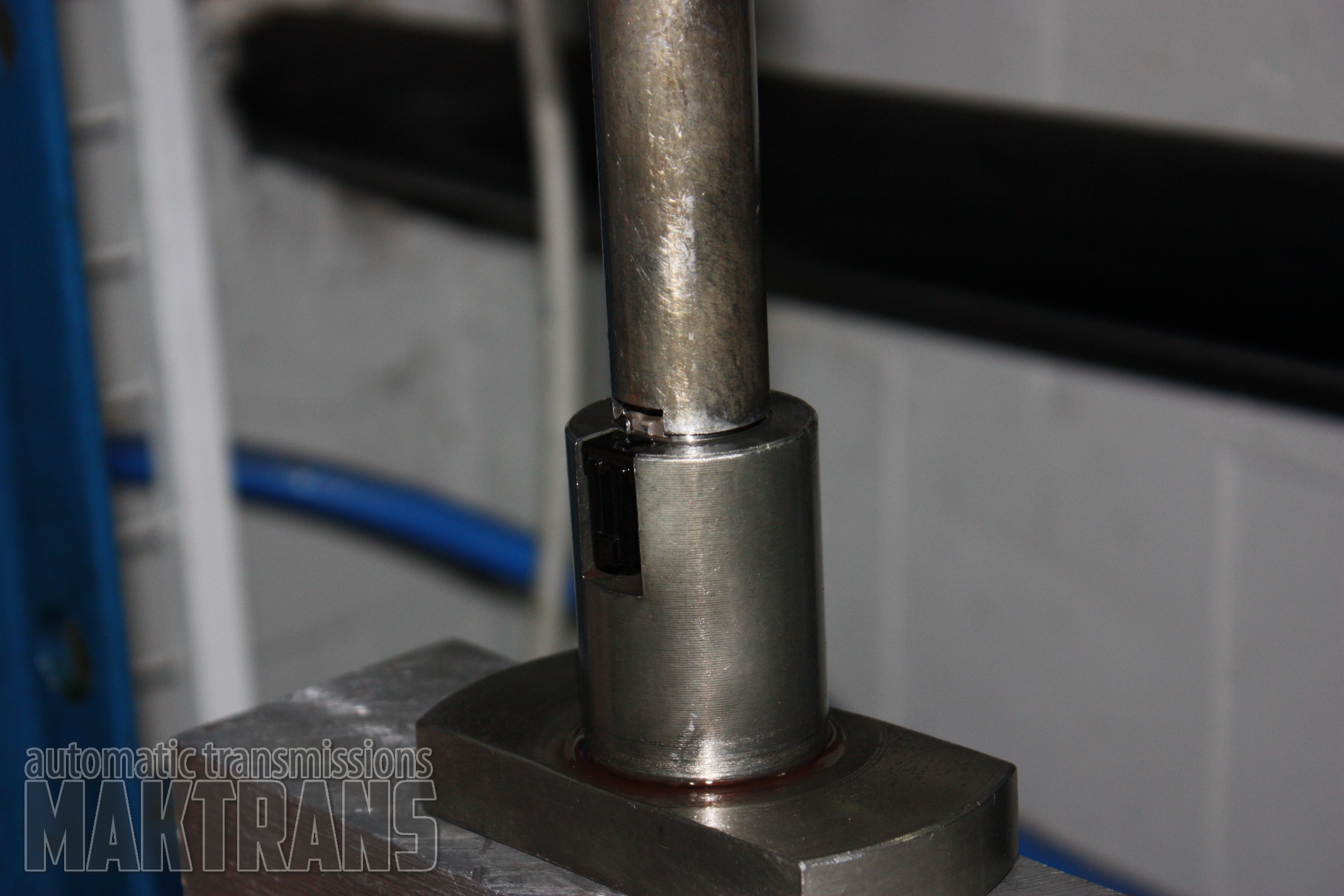

We collect and close the solenoid, we need a press and a special mandrel

After assembly - testing on the stand

|

|

The graph is ideal, such a solenoid will not just work properly, its resource (thanks to a better plunger coating) is much higher than the new original solenoid valve.

And now the most interesting thing is, remember the installation of solenoids from another Aisin box? They look like this:

:

This is a relatively new technique, the engineers of "Maktrans" company have found out that there is the possibility of installing non-native solenoids, for which it is only necessary to slightly alter the bracket for securing the solenoid to the body. Cars with such "strengthened" valvebodies have already traveled tens of thousands of kilometers and repeated diagnostics showed that this is a good and working way to extend the life of the gearbox.

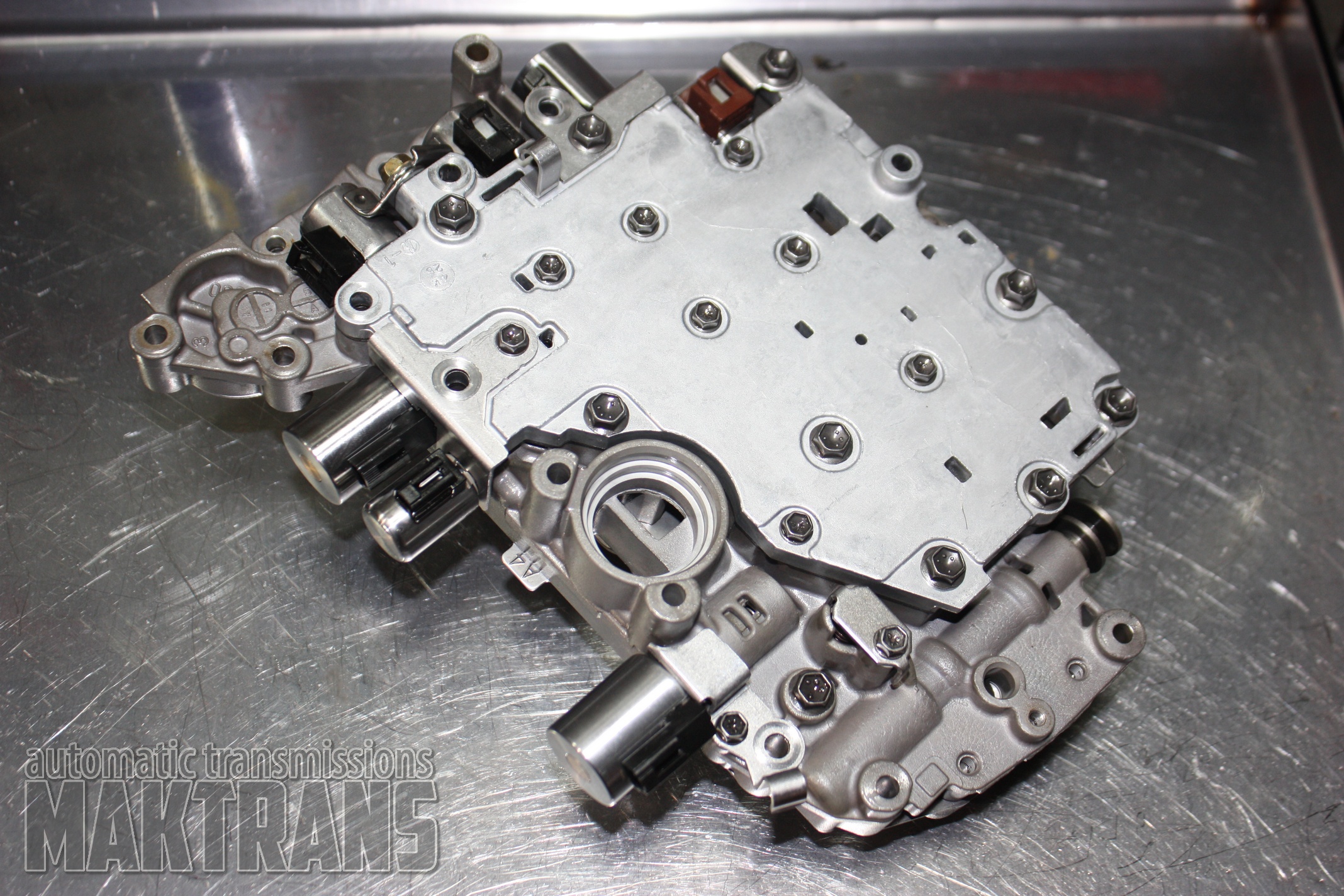

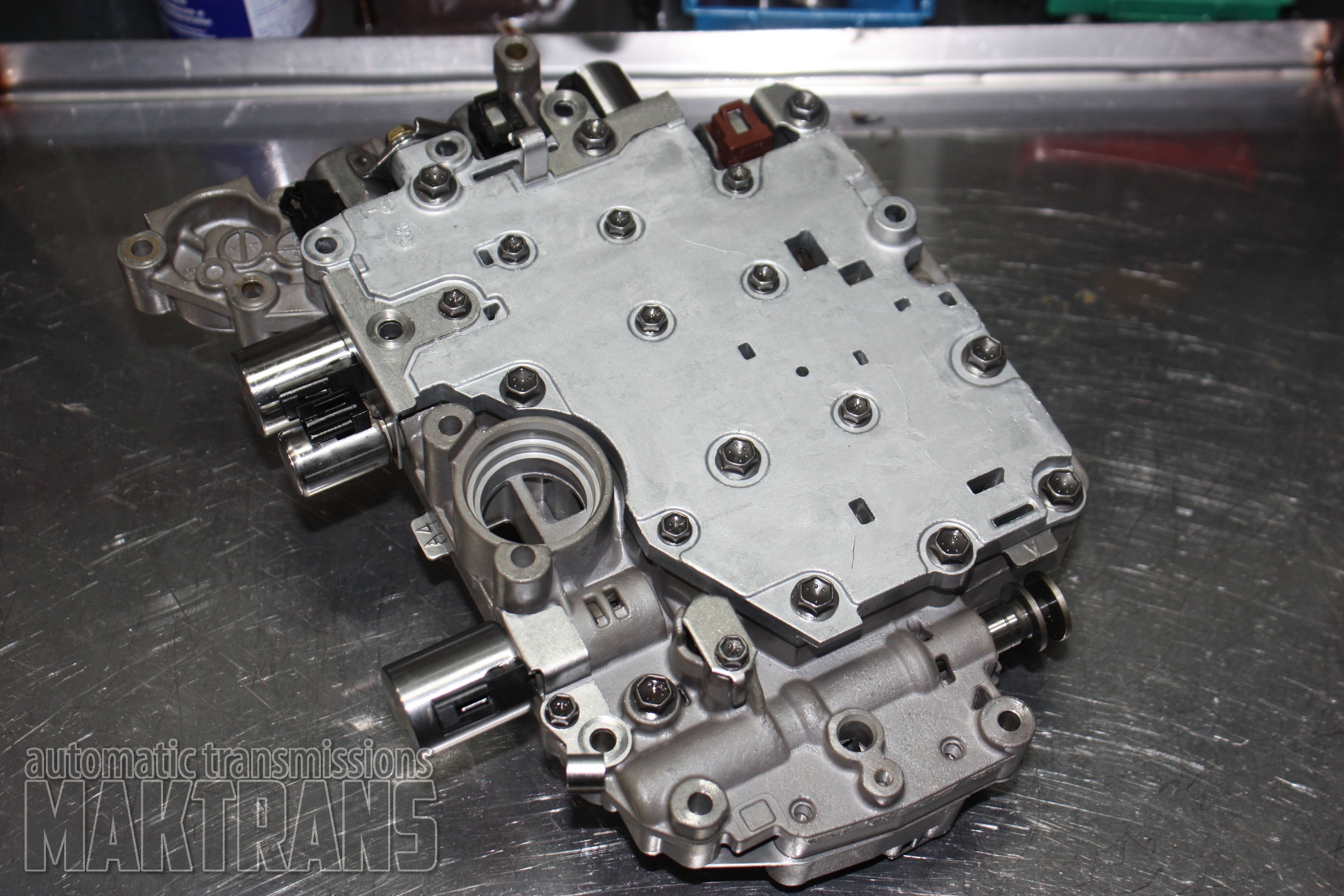

In the photo below - already reconstructed valveb with installed solenoids, ready for packing and shipment to the customer.

|

|

Finally - a couple of tips: when repairing the valvebody you need to simultaneously take off the rear cover of the automatic transmission (this can be done without removing the gearbox) and check the condition of the teflon rings in it. This weak point in general of all front-drive Toyota cars boxes, wearout of Teflon leads to an oil starvation of the Overdrive Direct drum and it burns out, and at the initial stage also there are shocks and bumps when the Drive mode is activated, which is similar to the problems with the hvalvebody.

If necessary, we offer the repair of the rear cover, consisting in the modernization of the stator by which the Teflon rings operate. From steel new beds are made for Teflon rings and pressed onto the hub pre-machined on the milling machine::

The second important point is the repair of the torque converter, which is generally the main source of oil contamination in the automatic transmission:

And as always a universal advice - ALWAYS when repairing the valvebody it is necessary to wash the transmission cooling system, if this is not done - after 100 km. mileage the gearbox may need another repair, because the valve block is very sensitive to the quality and cleanliness of the oil .

Payment

- PayPal (Payment to a PayPal account, without obtaining European VAT documents)

- Bank Transfer P2P only (Payment for private banking account, without the possibility of obtaining European VAT documents)

- Crypto Payment (If you want to make payment in cryptocurrency, without the possibility of obtaining European VAT documents)

- B2B sale with VAT ID: no VAT is charged (When buying for more than 300 euros, B2B sale with VAT IDfor countries VIES: no VAT is charged (With mandatory indication of the European VAT number and receipt of documents for the company) when buying for more than 300 euros

Shipping

We work with shipping companies like DPD, DHL, FedEx and we can ship worldwide. Shipping cost you can see during checkout and on product page (you can use button "Shipping Cost Calculator")

We are. In NJ. How. Many. Day is. For. Shipping

MAKTRANS

MAKTRANSHello, it's not a spare part, it's a service.