$0.00

Checkout- Brand: MAKTRANS-VB

- Product Code: TF80VBREBUILD

Product model copied to clipboard

- Weight (kg): 10

- Availability: 1001

| Stock Place: | Availability: | Qty: |

| Ukraine | 1001 pcs. |

|

- Product overview

- Shipping & Payment

- Questions - Answers (2)

- Related products (34)

AW TF-80SC / TF-81SC - 6-speed automatic transmission for front and all-wheel drive cars, are mostly installed on Mazda (6, CX7, CX9), Volvo (XC60, XC70, XC90), Opel (Insignia, Vectra), Peugeot (407, 408, 607), Hyundai VERACRUZ and Ford Mondeo. There are 2 main modifications for different engine volumes and torque - TF-80SC for engines up to 2 liters and TF-81SC for powerful motors from 2 to 4 liters - the design is the same, but the performance of some units is different - the number of friction plates in drums and so on . In addition to the differences in the iron part, the hydraulic and electric parts are different, for example the VOLVO and FORD valvebodies are seriously different and not interchangeable.

AW TF-80/81 – transmission is sufficiently reliable because it is a logical continuation of 4 or 5-gear AW50-40 and AW55-50 transmissions- only proven engineering solutions for years were used- such as in a torque converter - classic locking piston, not frictional plates as at 6-speed analogues of ZF and Mercedes. On the one hand, a simple design has made the automatic transmission reliable and maintainable, on the other - all the known problems of old transmissions are also present. One of them is a valvebody, the repair of which we will consider in this article.

This article will be useful not only to potential customers of "Maktrans" company who will see the whole process of regeherating the valvebody unit to the state of the new part, but also to the masters who repair the gearboxes themselves. Starting from this material, we will publish instructions for vacuum testing of the valvebody plates,which subsequently will lead to quick defining of problem channels and immediately move on to buying oversized plungers that will solve the problem.

Useful information- there is a twin brother ofAW TF-80, this is also a 6-speed automatic transmission AW TF-60SN (09G) which VAG has installed almost for its entire lineup. They are very similar, including valvebodies - so much that some plungers are exactly the same. We have an article about the repair of the 09G valve block, it can be found easily. All that is written in it is true for TF-80, if we talk about hydraulics.

Specialists of "Maktrans" company repair such valvebodies using their own developments - enlarged bushings, plungers, reamers, tools for opening and closing the body of solenoids. We will tell how it happens and how much it costs. Let's start with pricing.

The cost of any repair of the valvebody that we perform always consists of 2 components, - work and consumables. It is calculated as follows:

| Work | Price |

|---|---|

| Diagnosis (disassembly, washing, vacuum testing, visual inspection and inspection of plungers for jamming) | 100$ |

| Testing solenoids on the stand - $ 5 a piece. In the block there are 6 solenoids. | 30$ |

| Solenoids regeneration- $ 40 per piece. | 240$ |

| Drilling valvebody channels and installing enlarged valves. Reaming of one hole is $ 20, the plunger is $ 11. We put 3 plungers and 2 booster valves. | 115$ |

| Assembly and final inspection | Free of charge |

Total 485 $. This option will ensure 100% performance, warranty - 1 year without mileage limitation. The situation is possible when there is no wearout in hydraulics, so there is no need for valves - the total cost is only $ 370

In addition to complex repairs, there are other options:

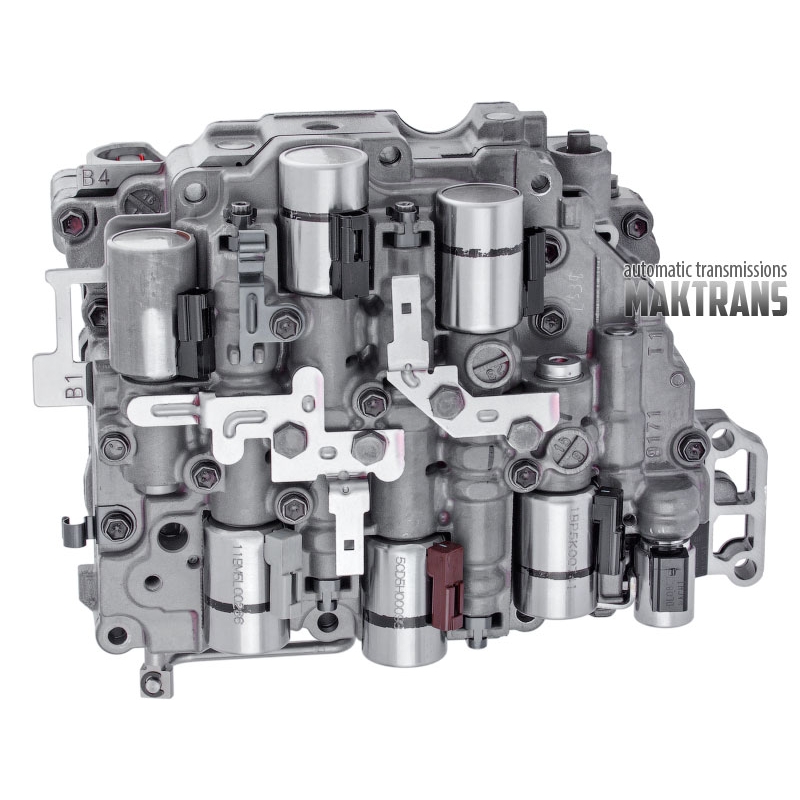

1. Purchase of already regenerated valvebody - $300

2. According to specialist` command it is possible to check and clean the solenoids, or to ream the desired hole and install an oversized plunger.

Getting Started

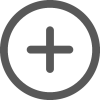

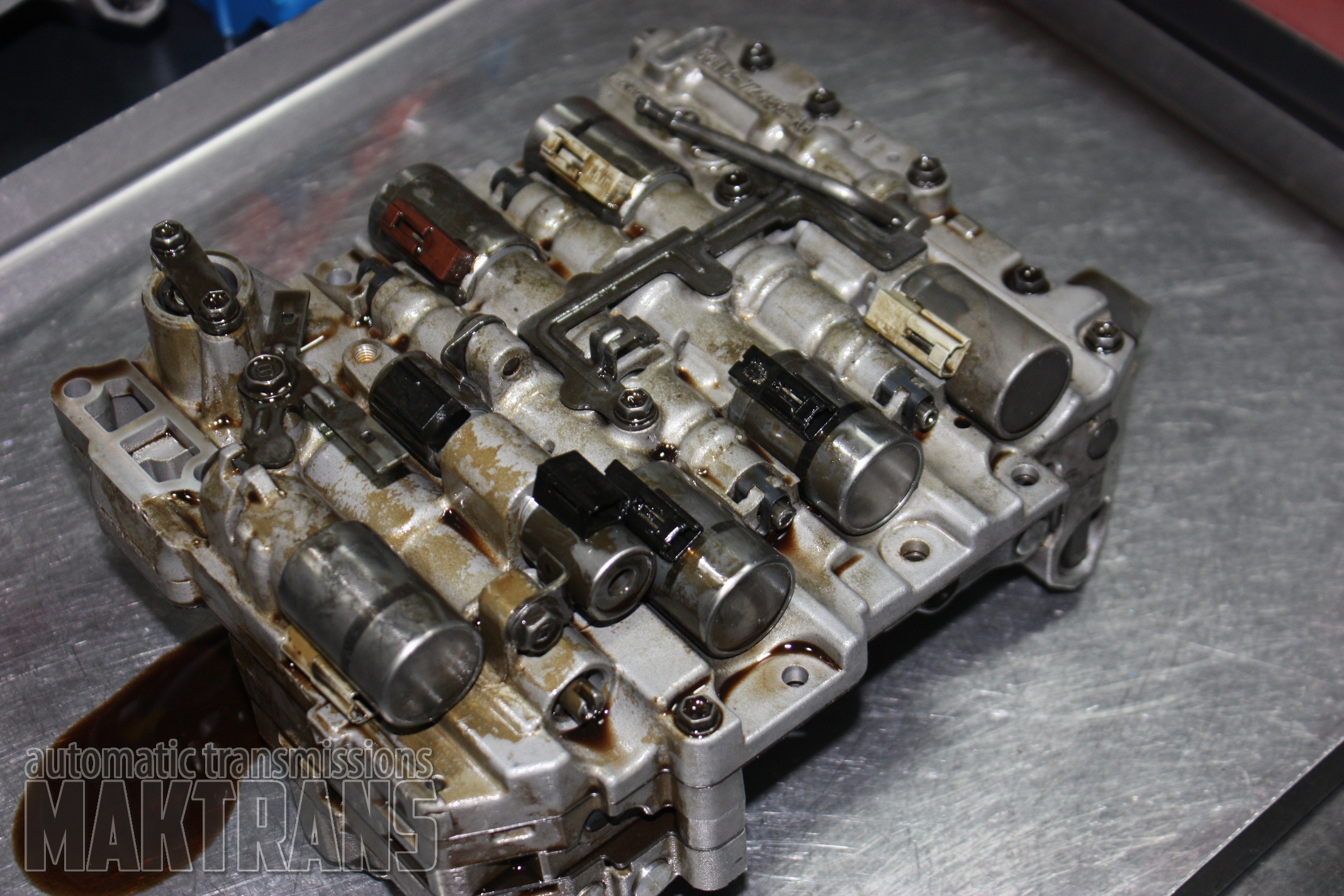

We have got Mazda CX9 valvebody with the symptoms:

• Thump when shifting into Drive;

• Slipping when switching from 3 to 4 and from 4 to 5 gears;

• Jerk when shifting reverse gear.

|

|

|

|

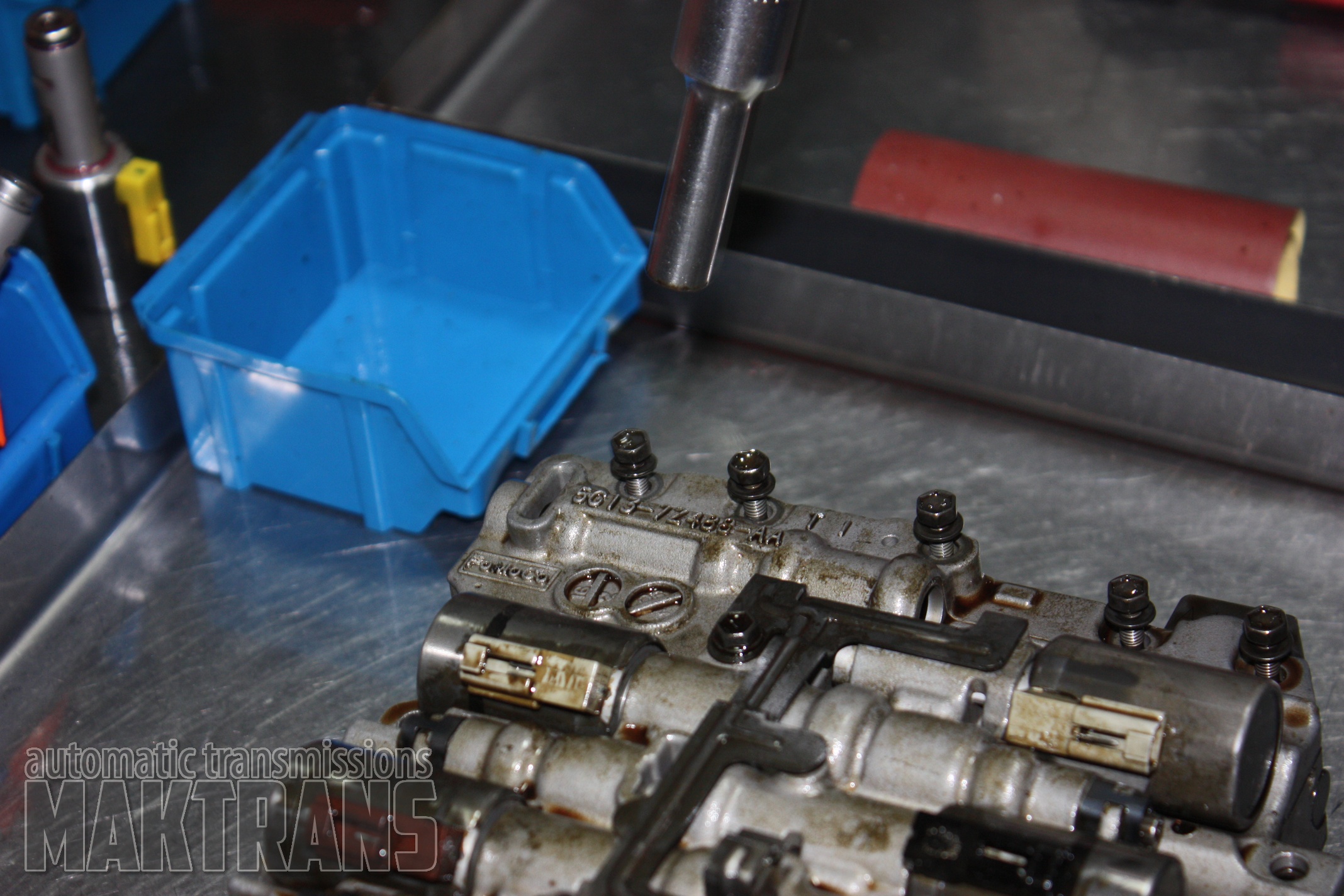

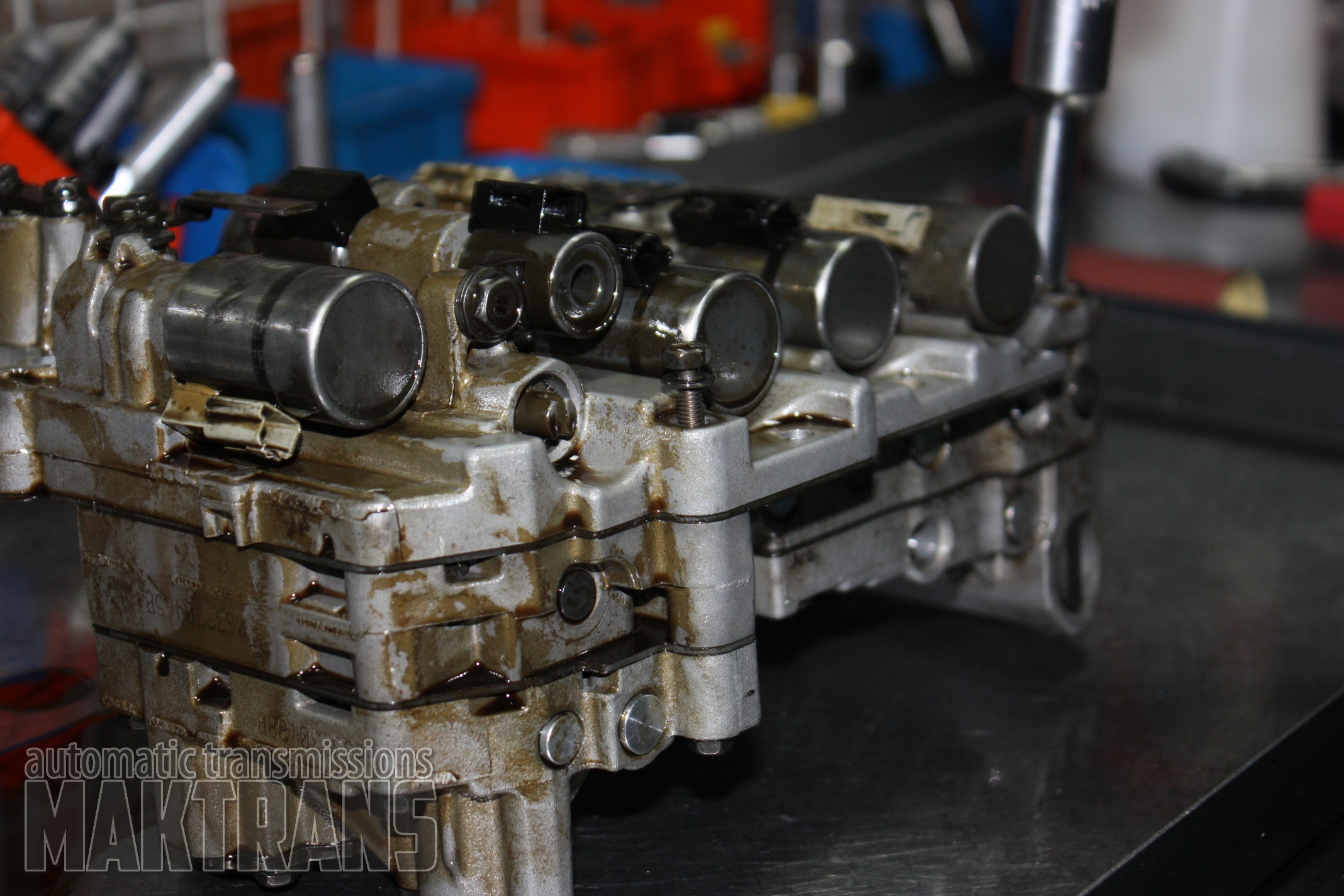

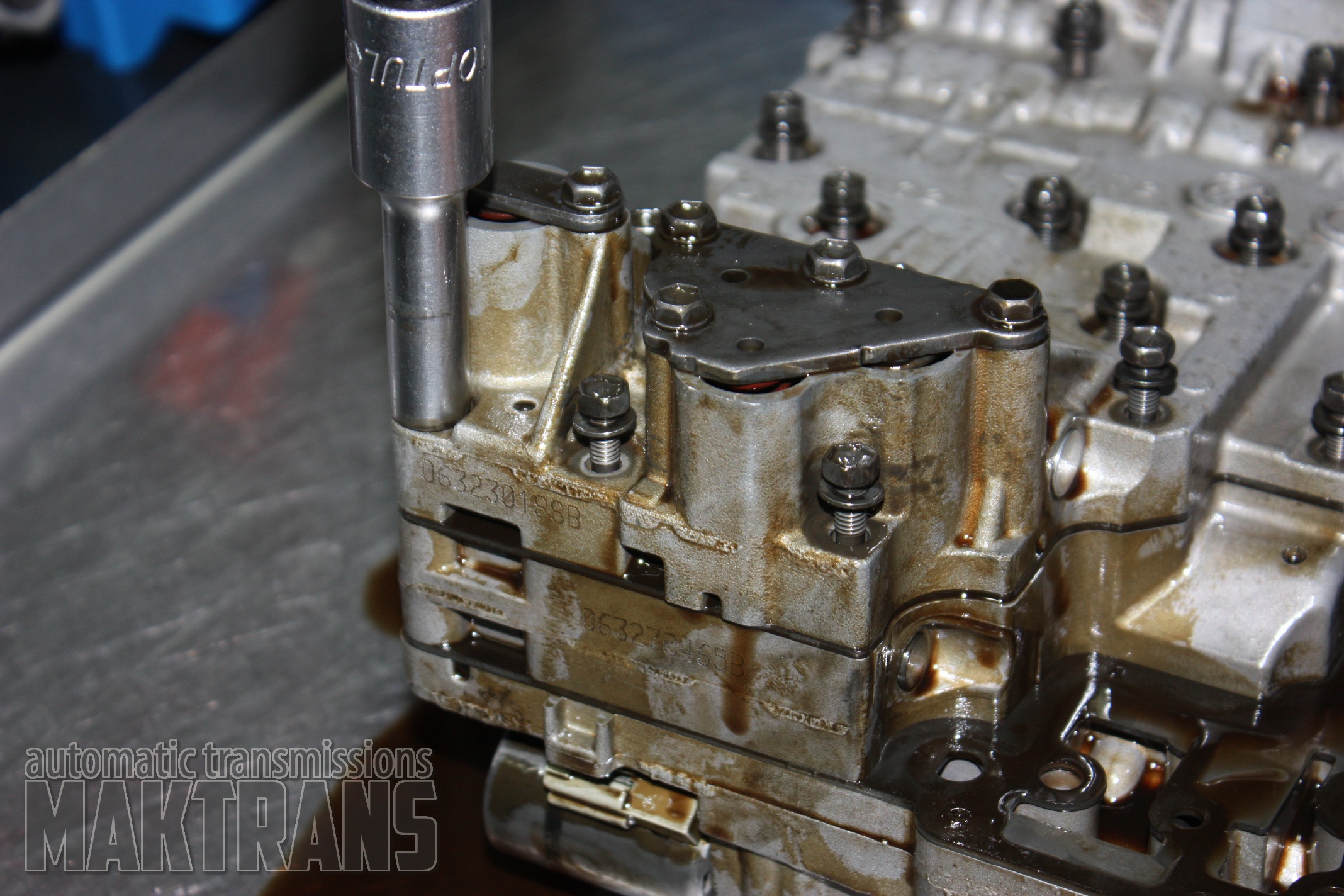

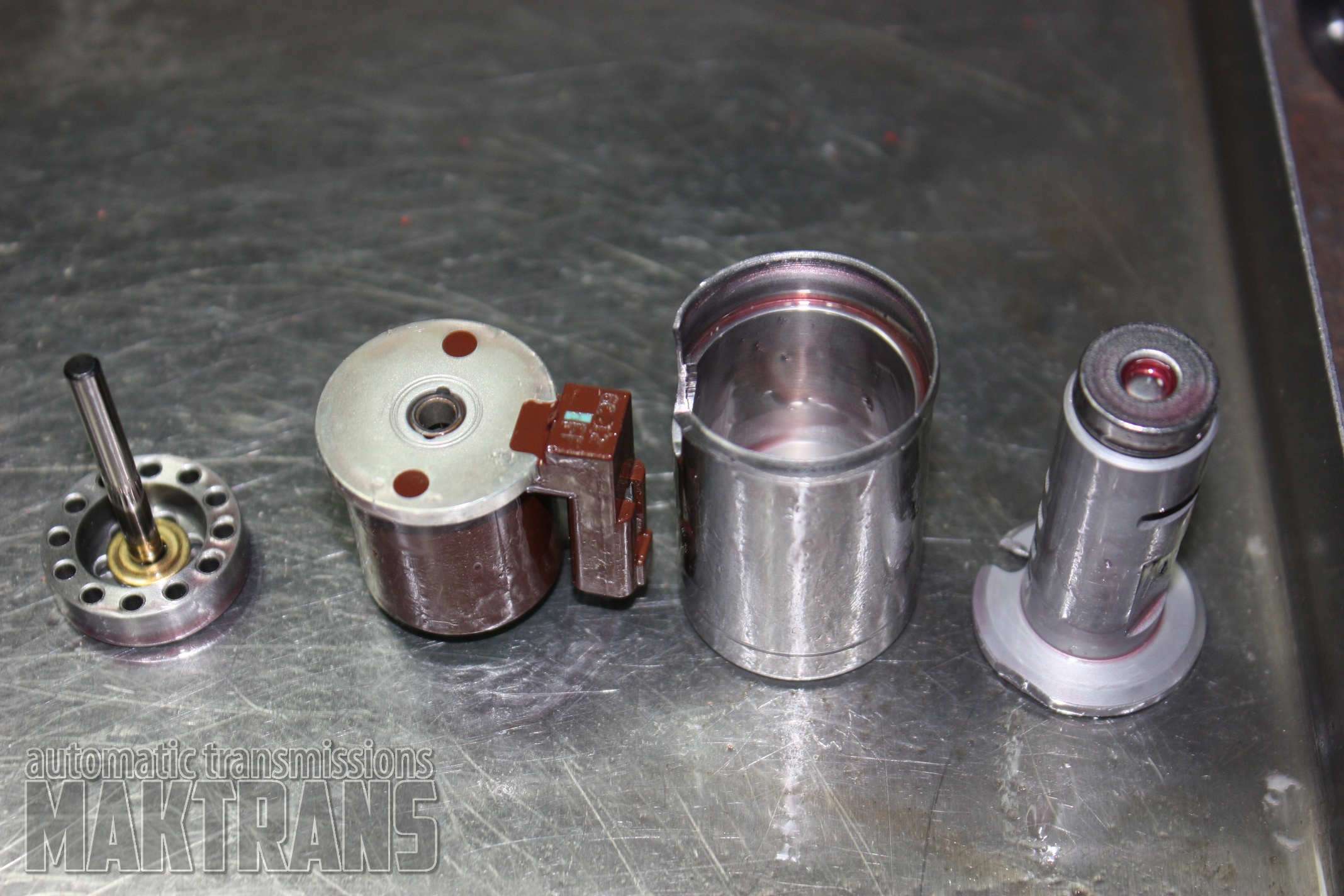

Disassembly

|

|

|

|

|

|

|

|

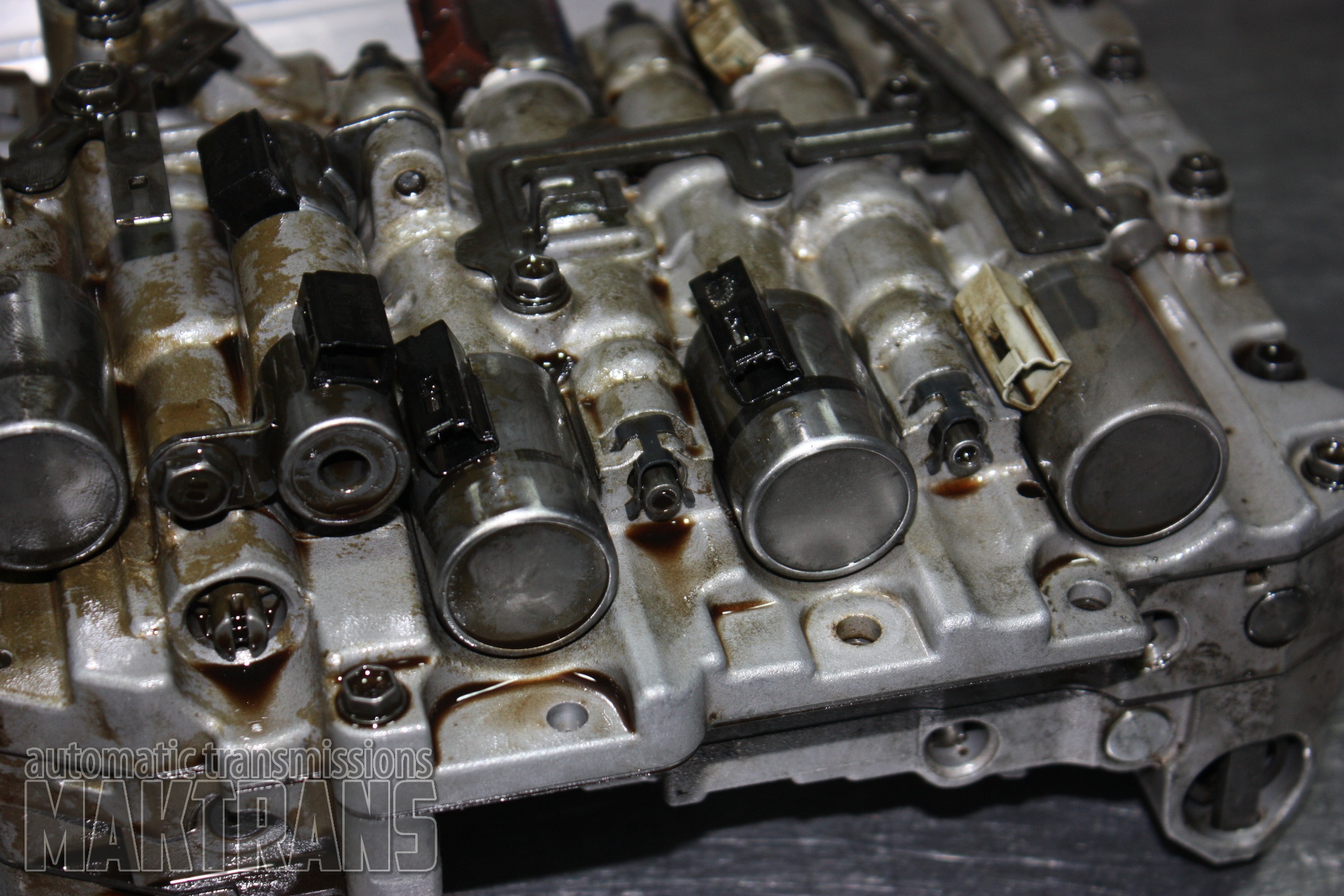

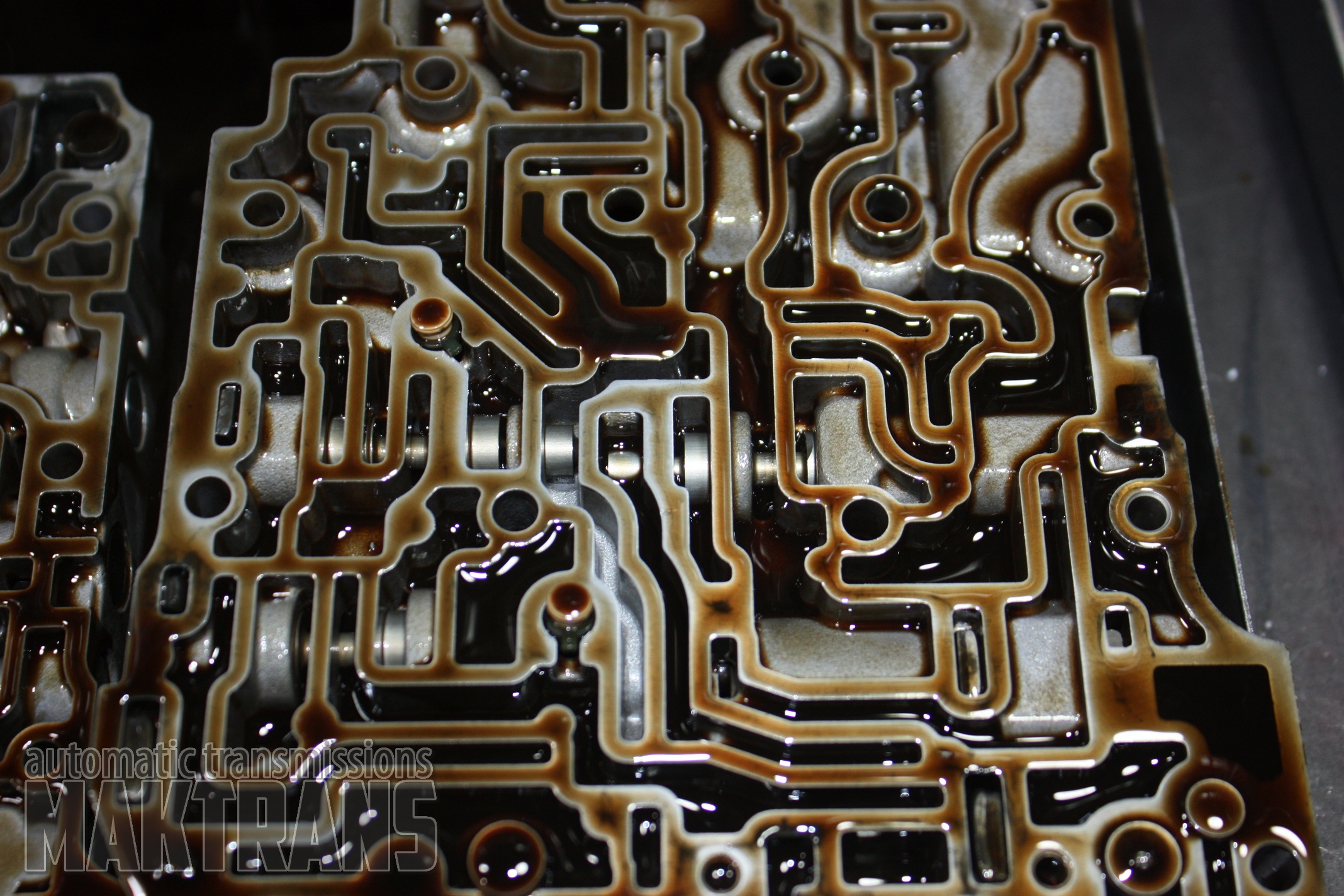

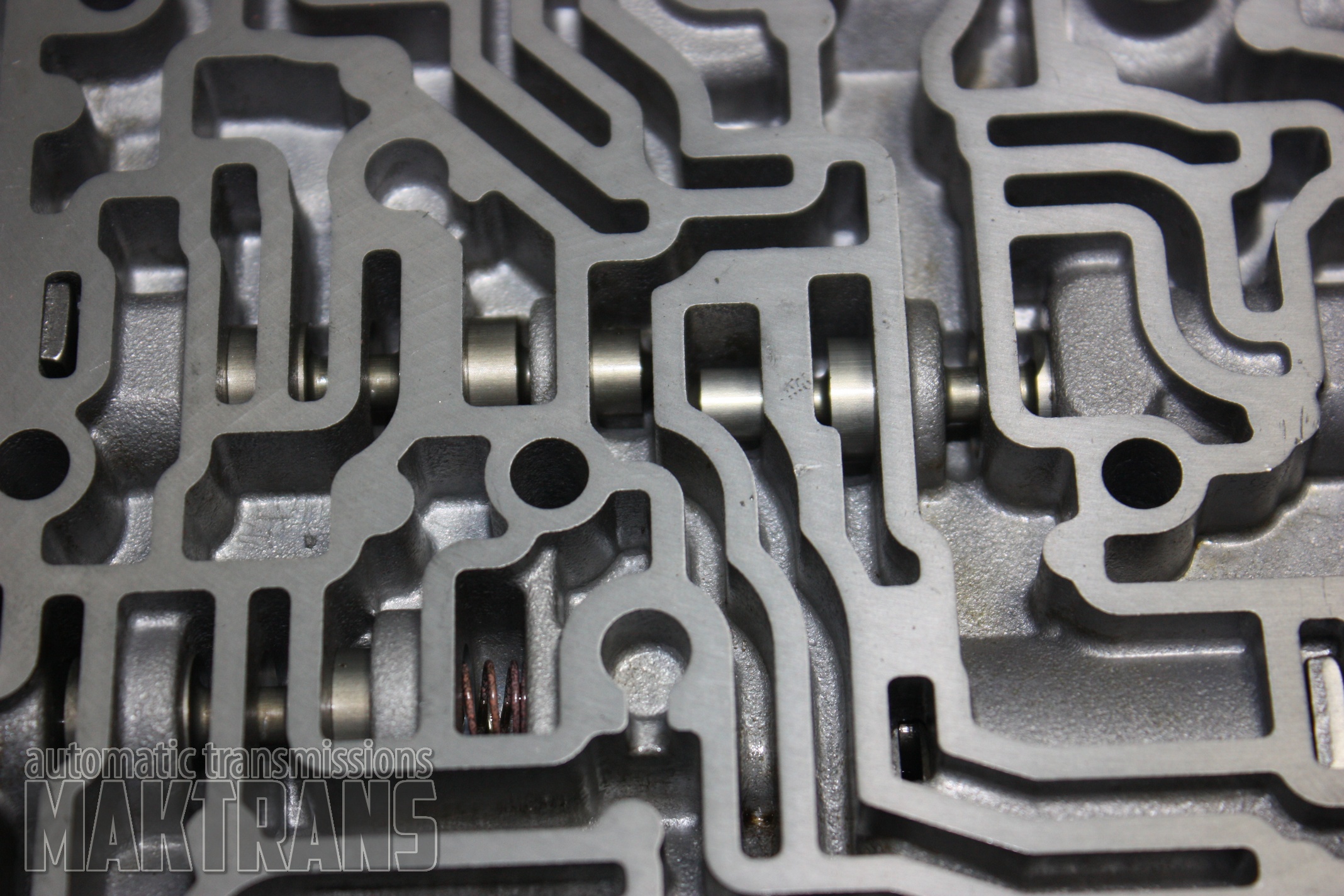

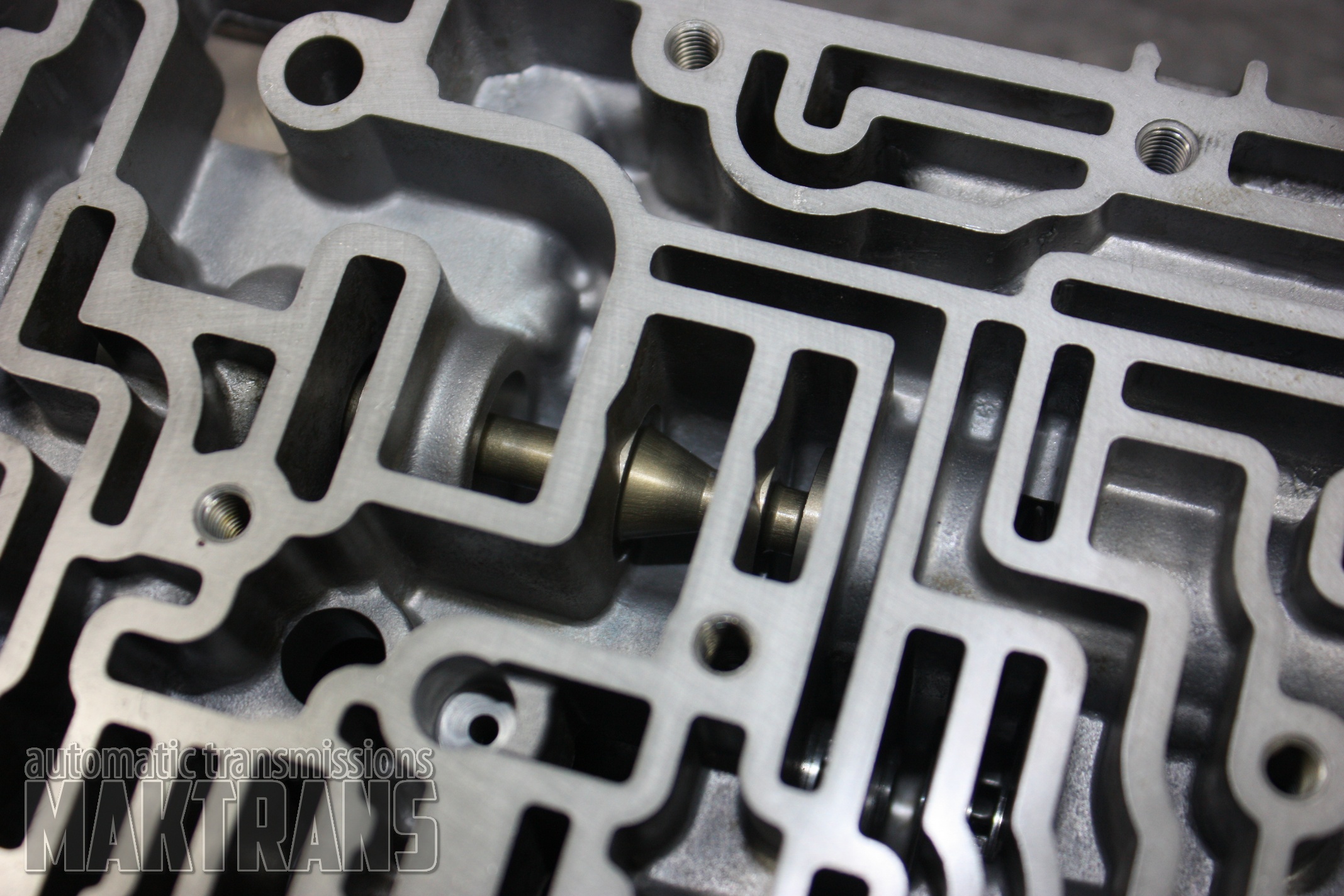

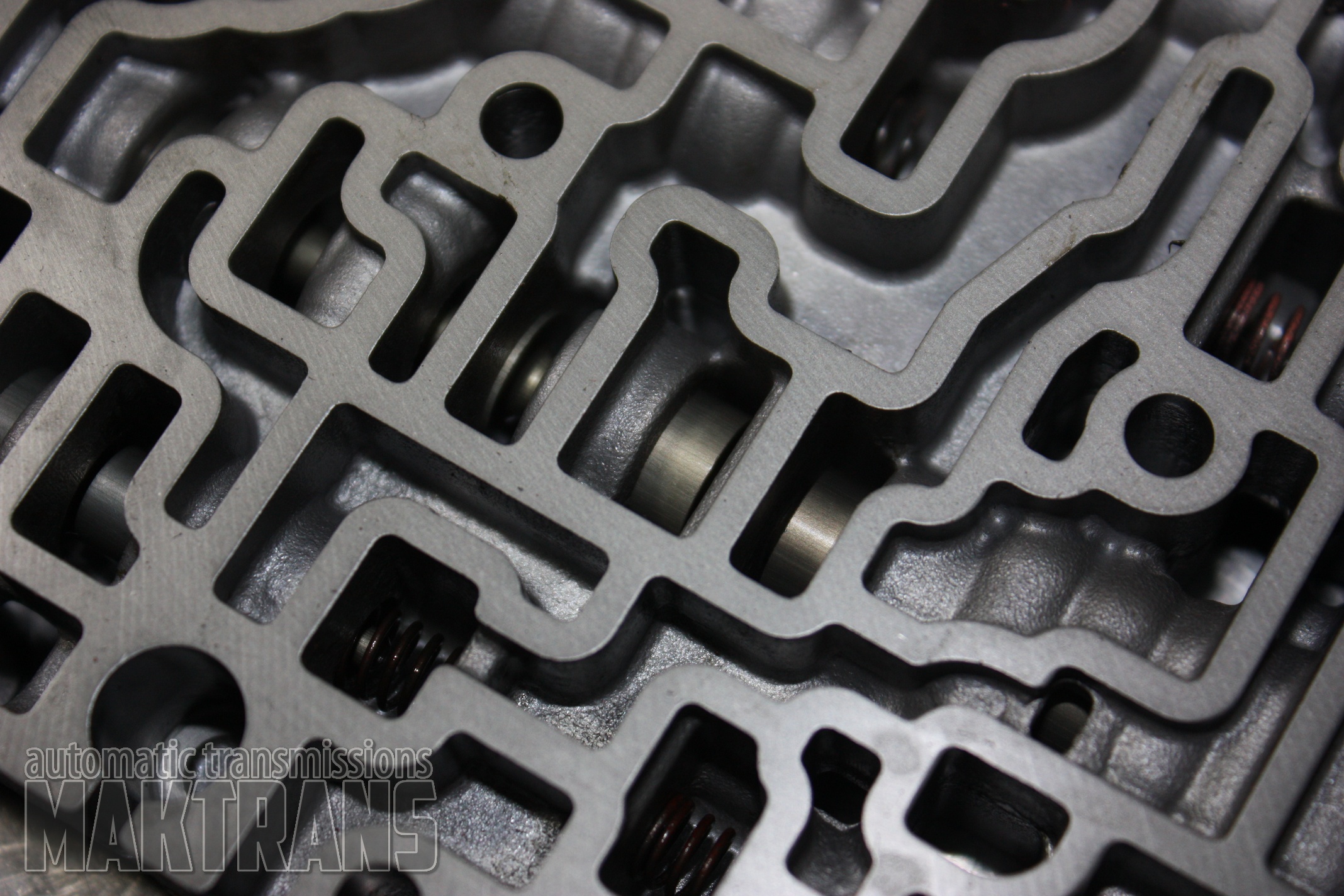

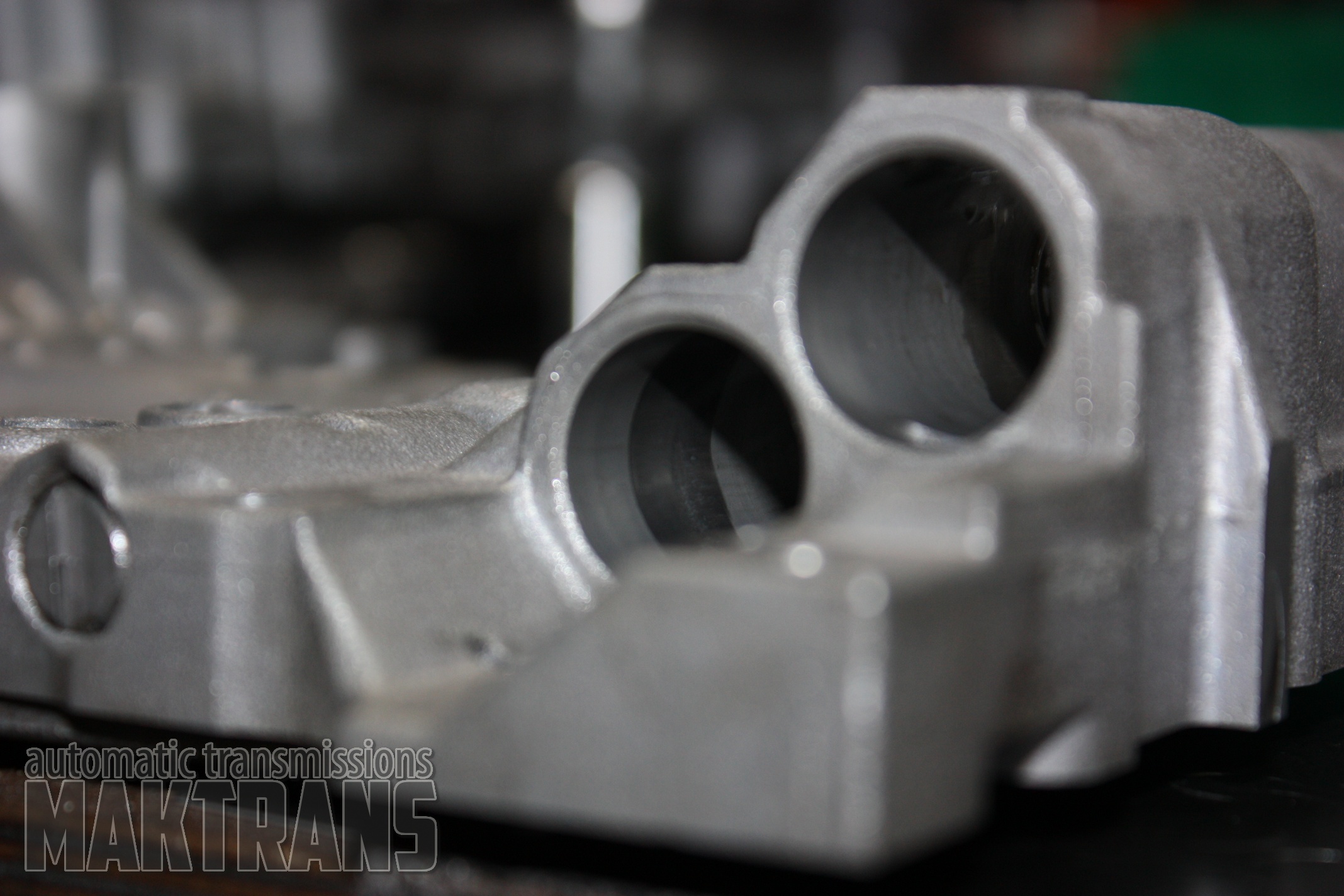

Already at this stage problems will sometimes be noticeable, we immediately look at the often worn sections of the valvebody. In the case of the TF-80 / TF-81, these batteries (the weak spot in general of all Aisin Warner automatic transmissions, from the 4-stage 90's to the modern 8-speed transmissions) at the top of the unit, 2 modulators and almost always there is a problem with high-loaded torque converter lock-up valve.

On the left - the channels in which the batteries work, to the right - modulators and Lock up.

|

|

Remember, at the beginning of the article, we said that the TF-80 used simple technological solutions, including the TCC with the locking piston? This is both plus and minus. Plus - the simplicity of construction and the cost of repairs, minus the same - the frictional layer from the locking piston in the process of operation exfoliates and falls into the valvebody, which does not like this much.

Often, this part is the main culprit of the problem with the hydraulic part, so it should also be repaired, you can send us along with the valvebody:

Typical repair of the AW TF-80SC coupler will cost ~ 120 $, for regular customers - ~ 80 $. We will cut the coupling, diagnose it, replace the seals and friction material on the locking piston, weld it back and check for leaks and runout.

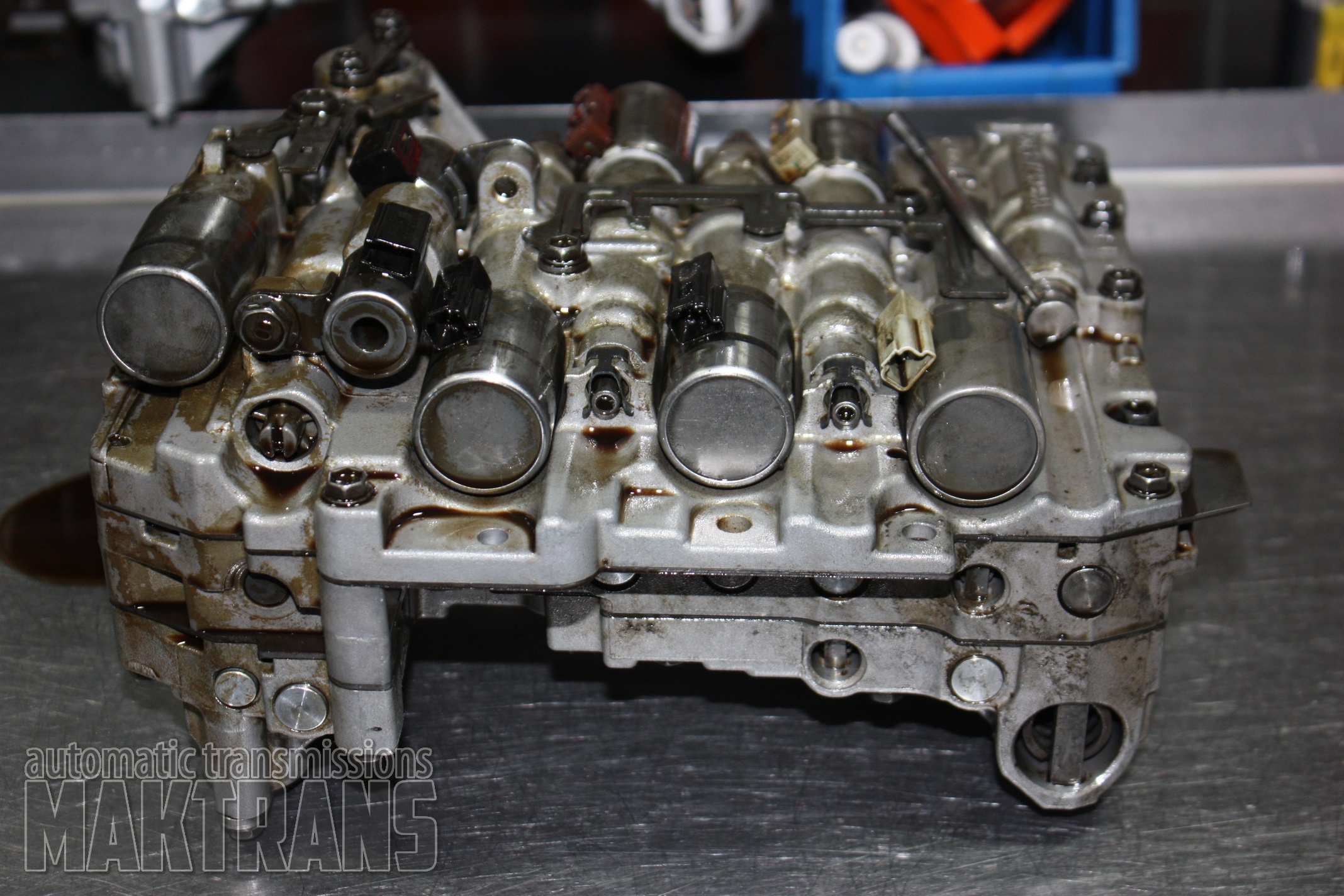

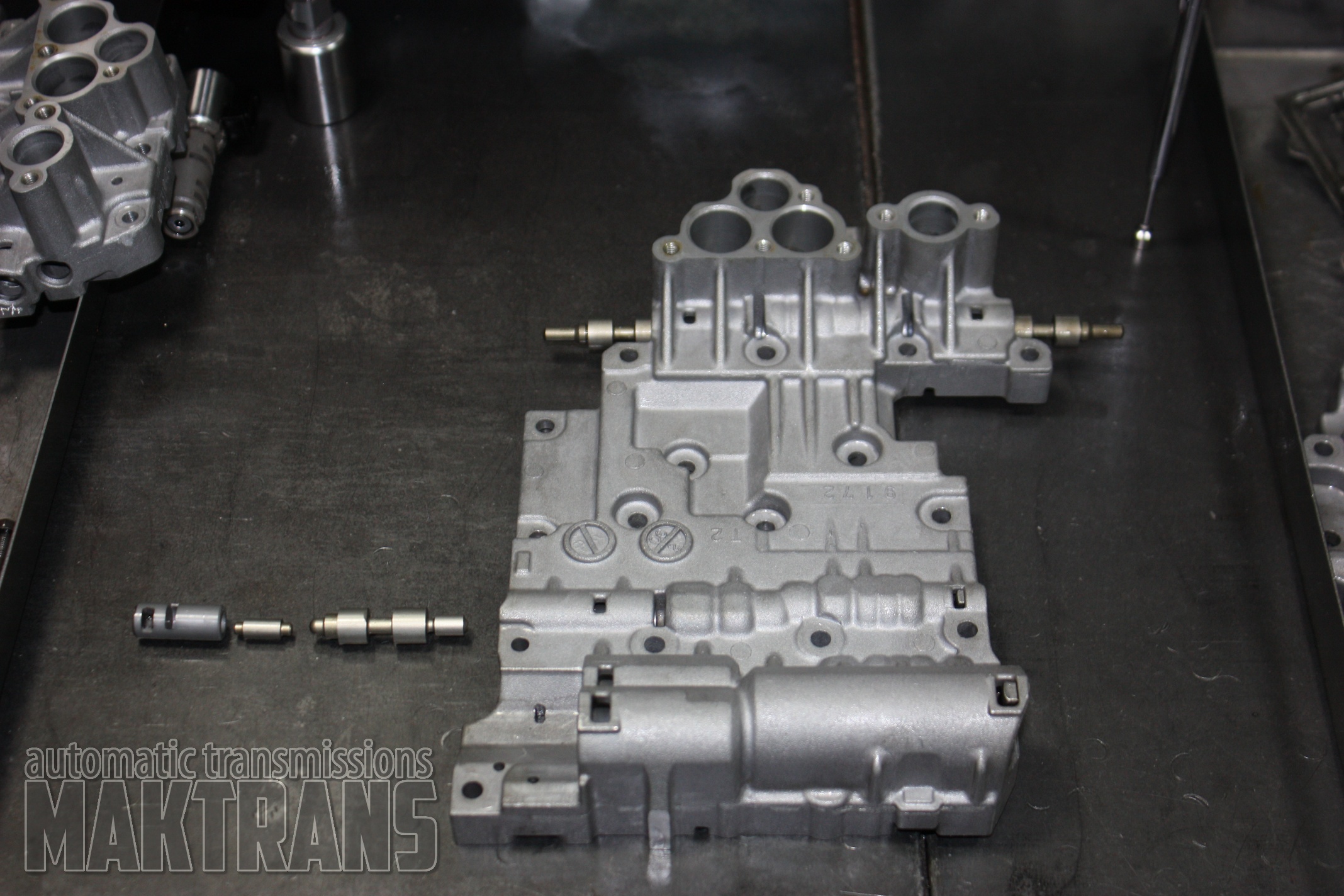

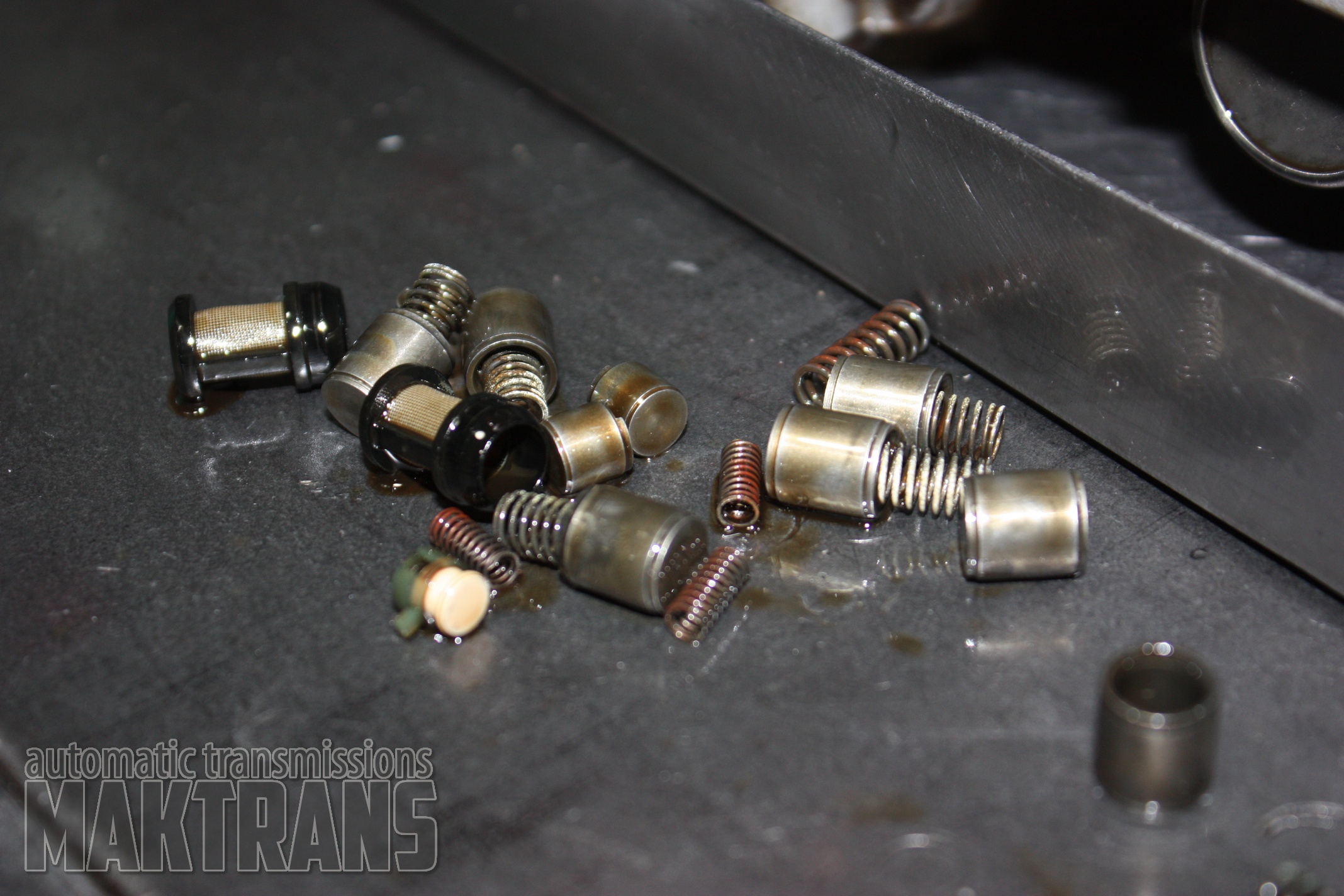

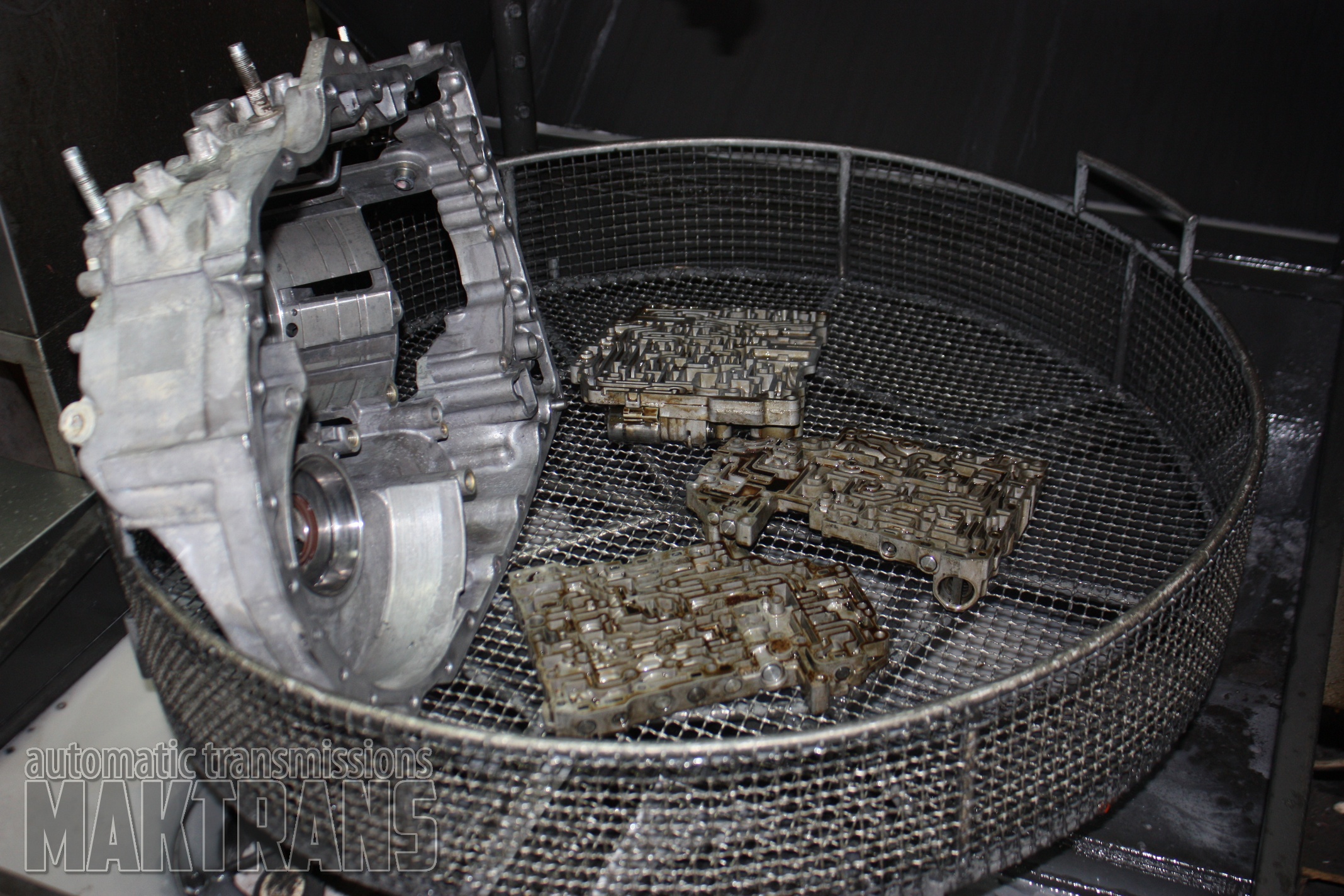

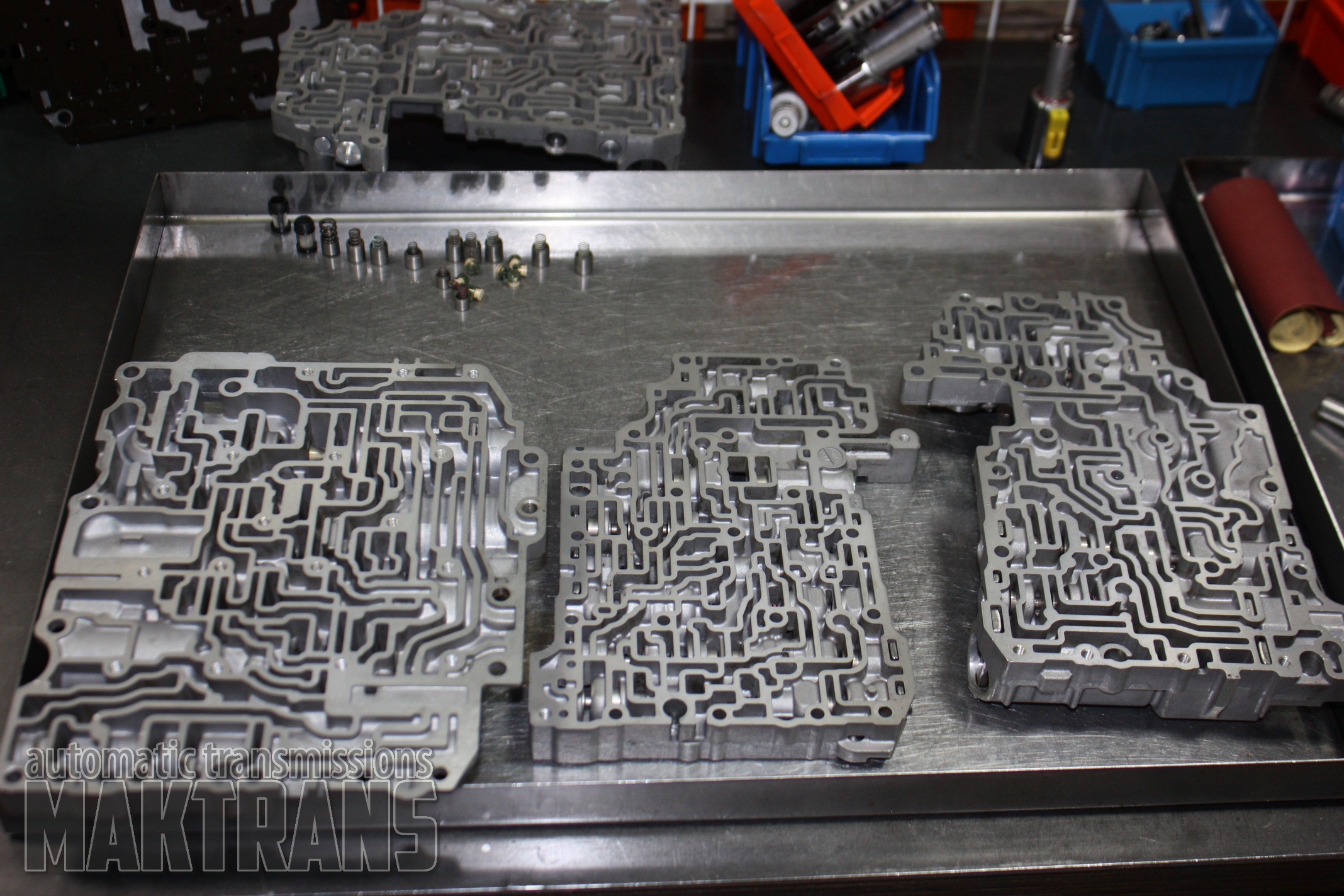

We return to the valvebody. Disassembled into individual plates, all the fine details (filters, springs, pistons, carefully extracted and folded so as not to be lost). We put parts of the valvebody to a special automatic washing machine and while our plates are washed - we pass to checking the solenoid valves.

|

|

|

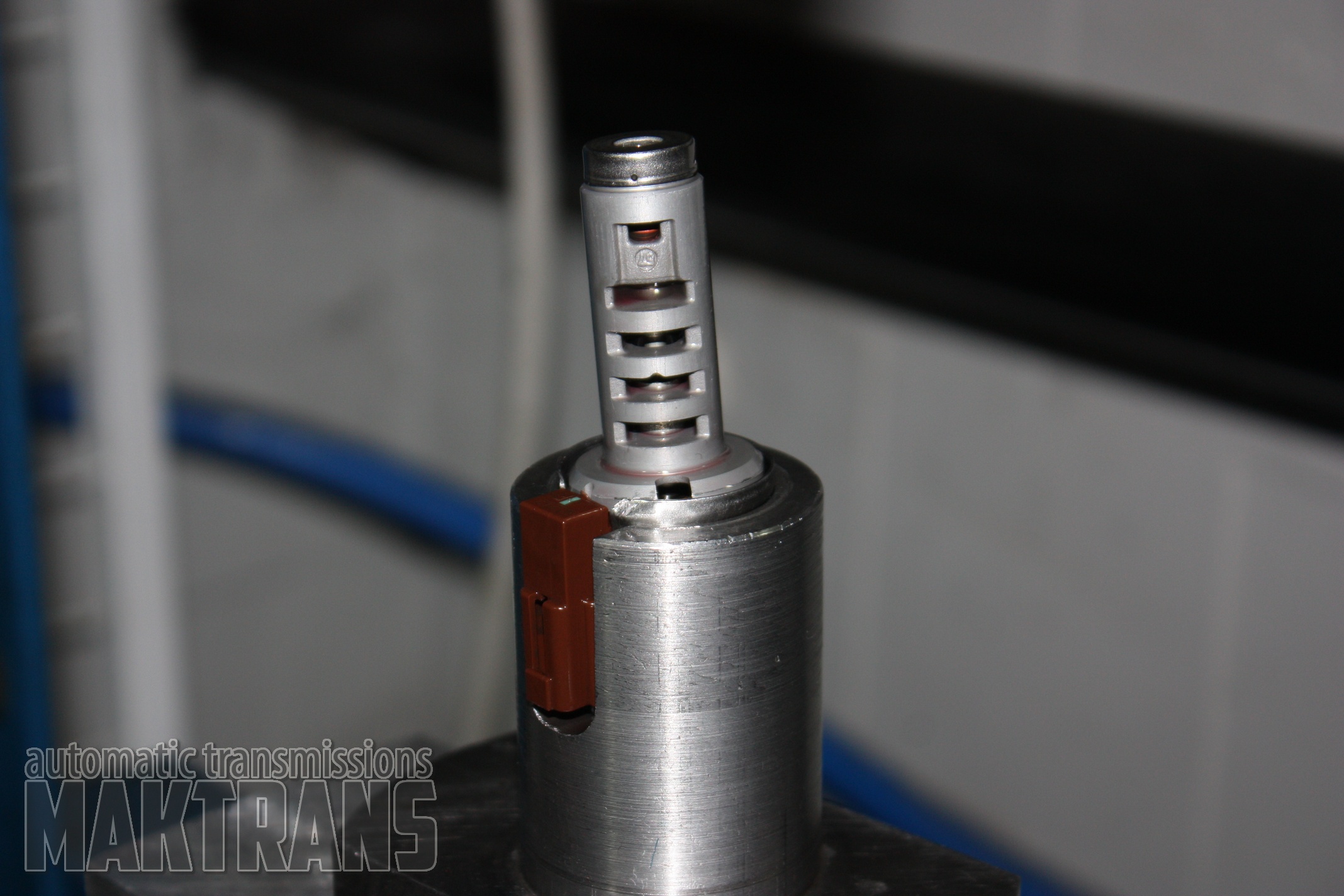

Repair of solenoids

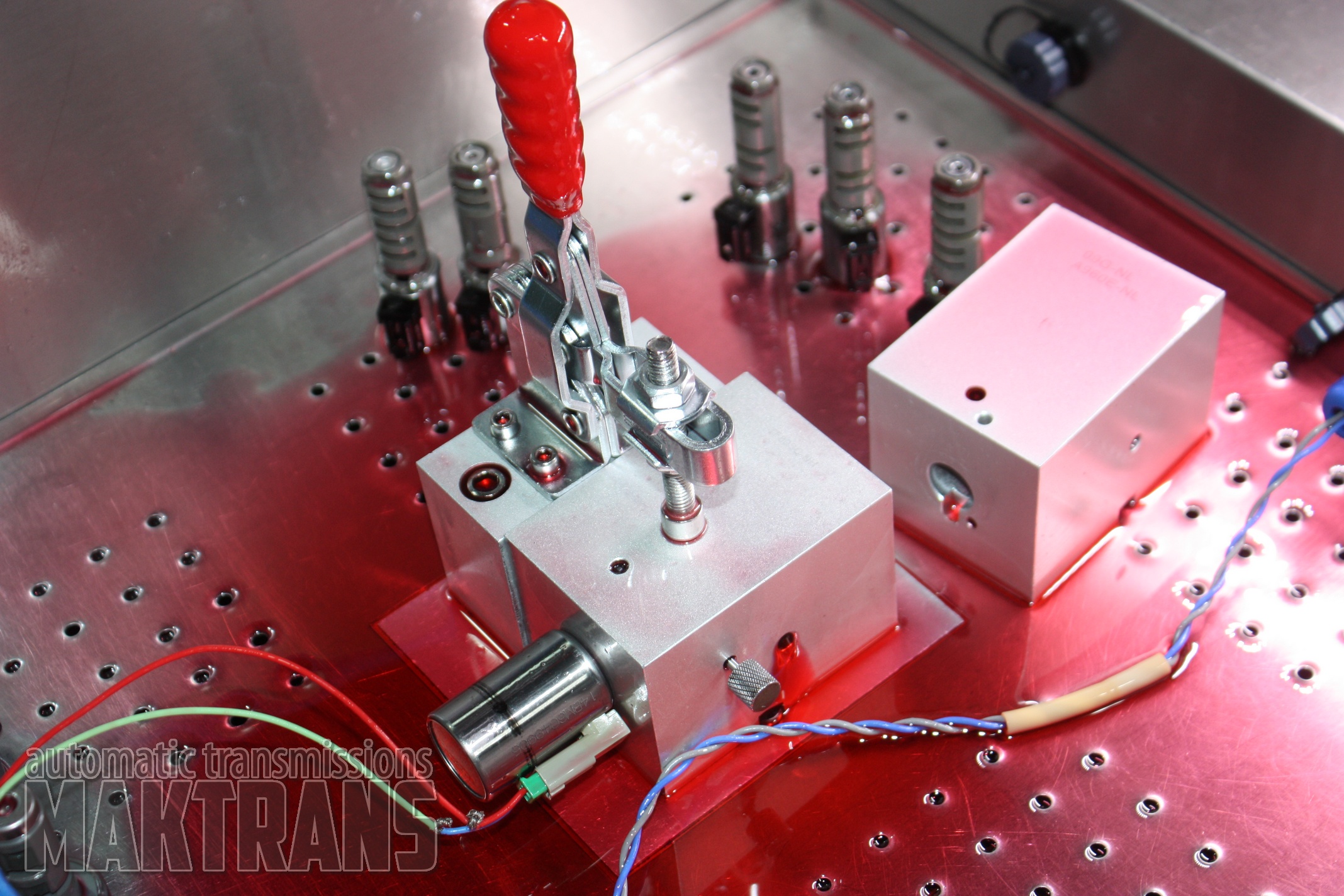

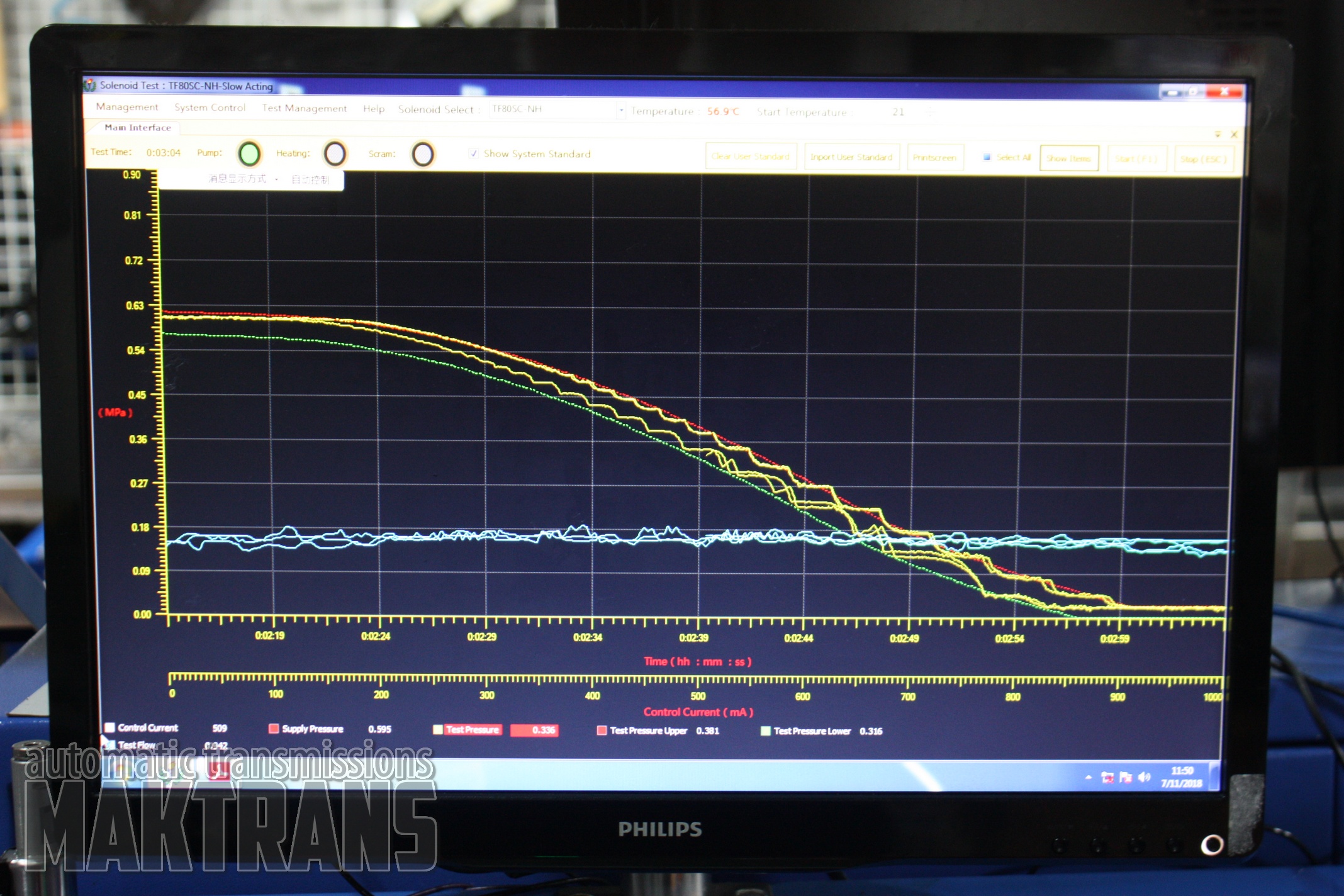

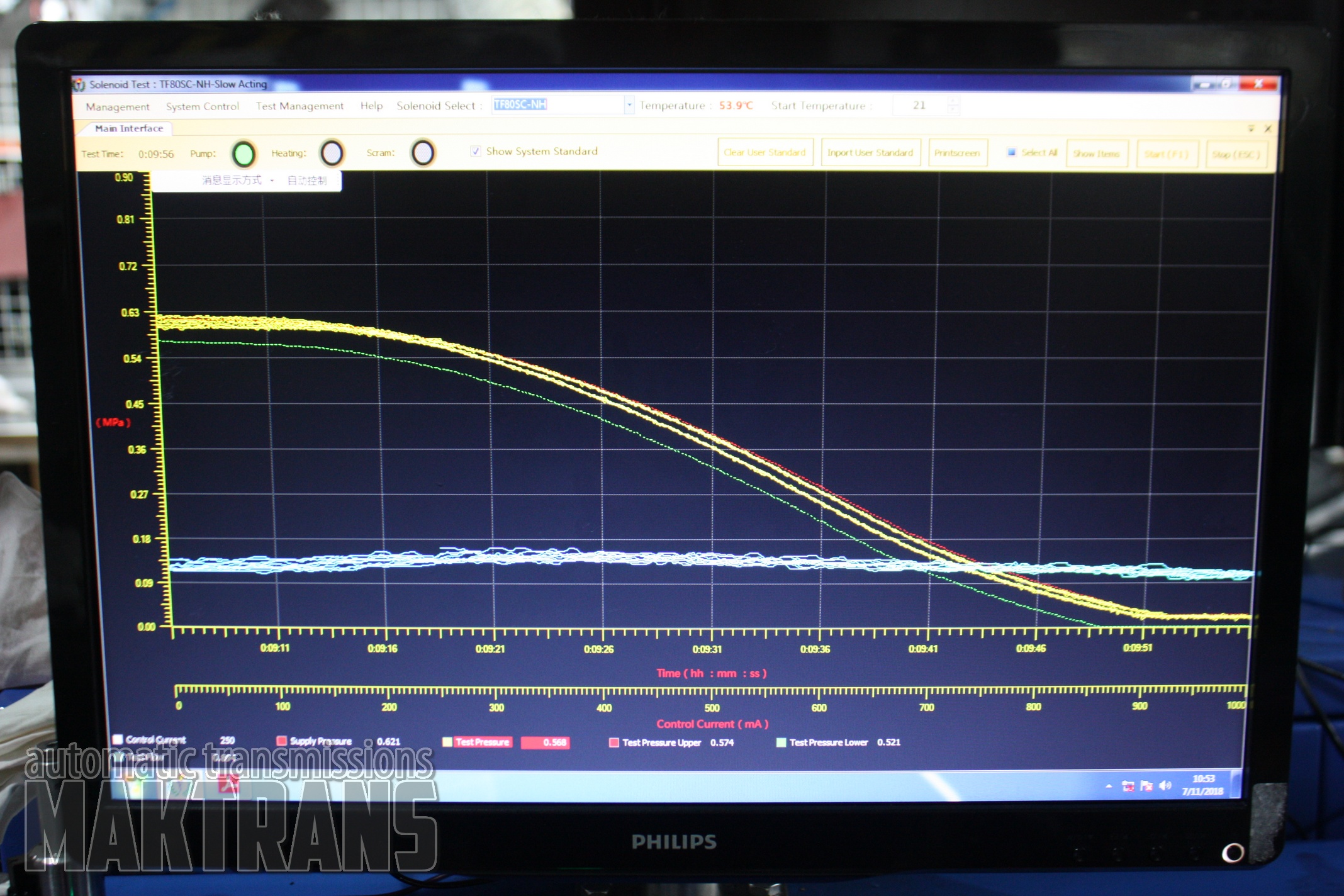

Step one, the solenoid through a suitable adapter is installed in the test bench and tested. The stand itself regulates the pressure and temperature of the oil, and gives the control commands. In the testing process, a graph is drawn, the master understands if there are any problems with the opening - closing the valve, or not. Steps on the graph - jamming the plunger inside the solenoid, a similar valve malfunction for the driver can be expressed in thumps when switching, or slipping

The connection between the faulty solenoid valve and thumps can be explained simply by approximate understanding the gearshift principle in the AT. There are clutch drums inside which there are pistons, friction and steel plates. To turn on the gear, you need to direct the oil into a certain drum, the piston will compress the clutches and secure the clutch. If the valve of the solenoid hangs for a long time in the open position - too much transmission fluid enters the drum and the pressure rises sharply - the driver sees this as a blow or a jerk when switching. If the valve on the contrary does not provide the desired pressure on the piston - will slip.

We check all the solenoids, if we see the graph as in the photo below - we need repairs.

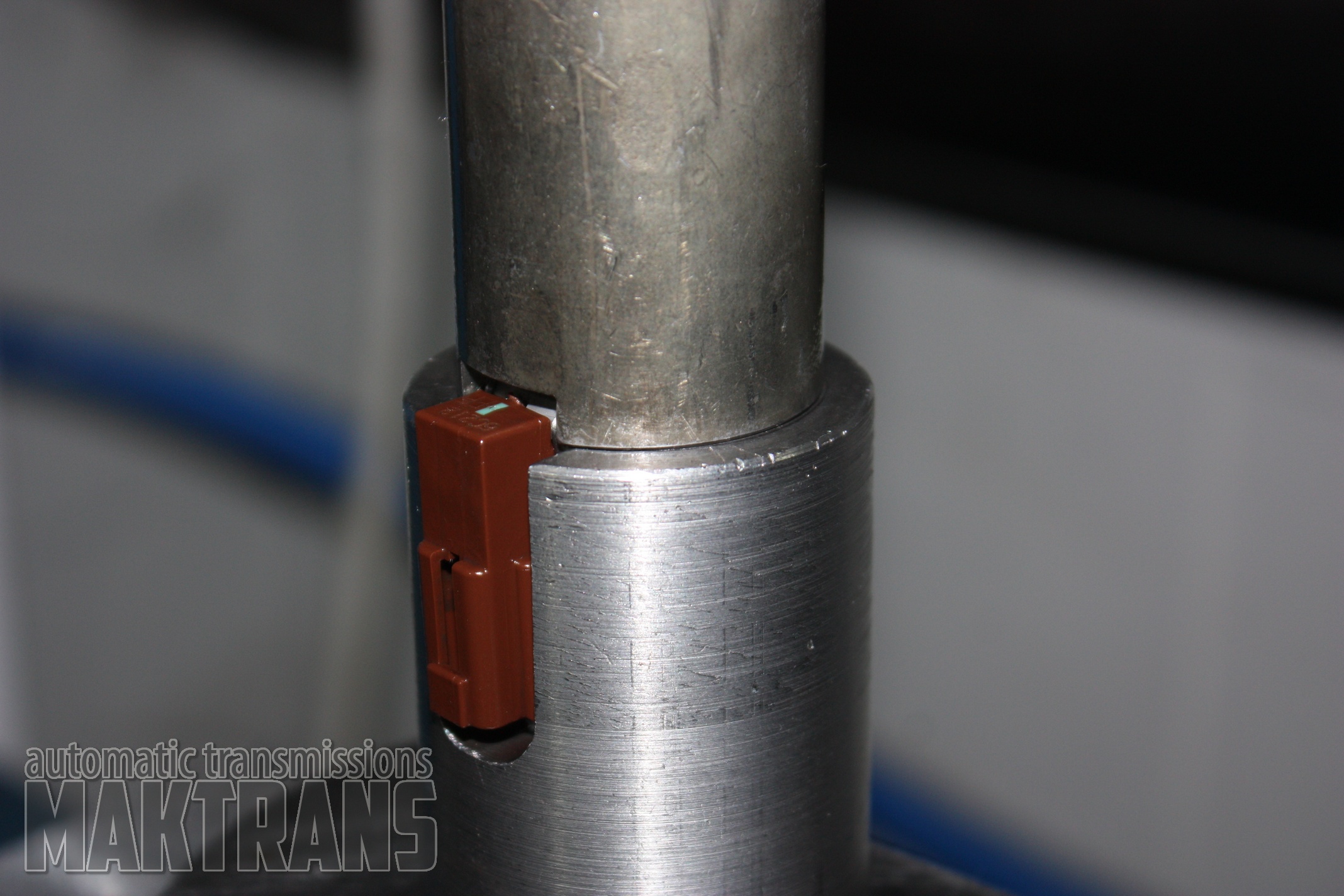

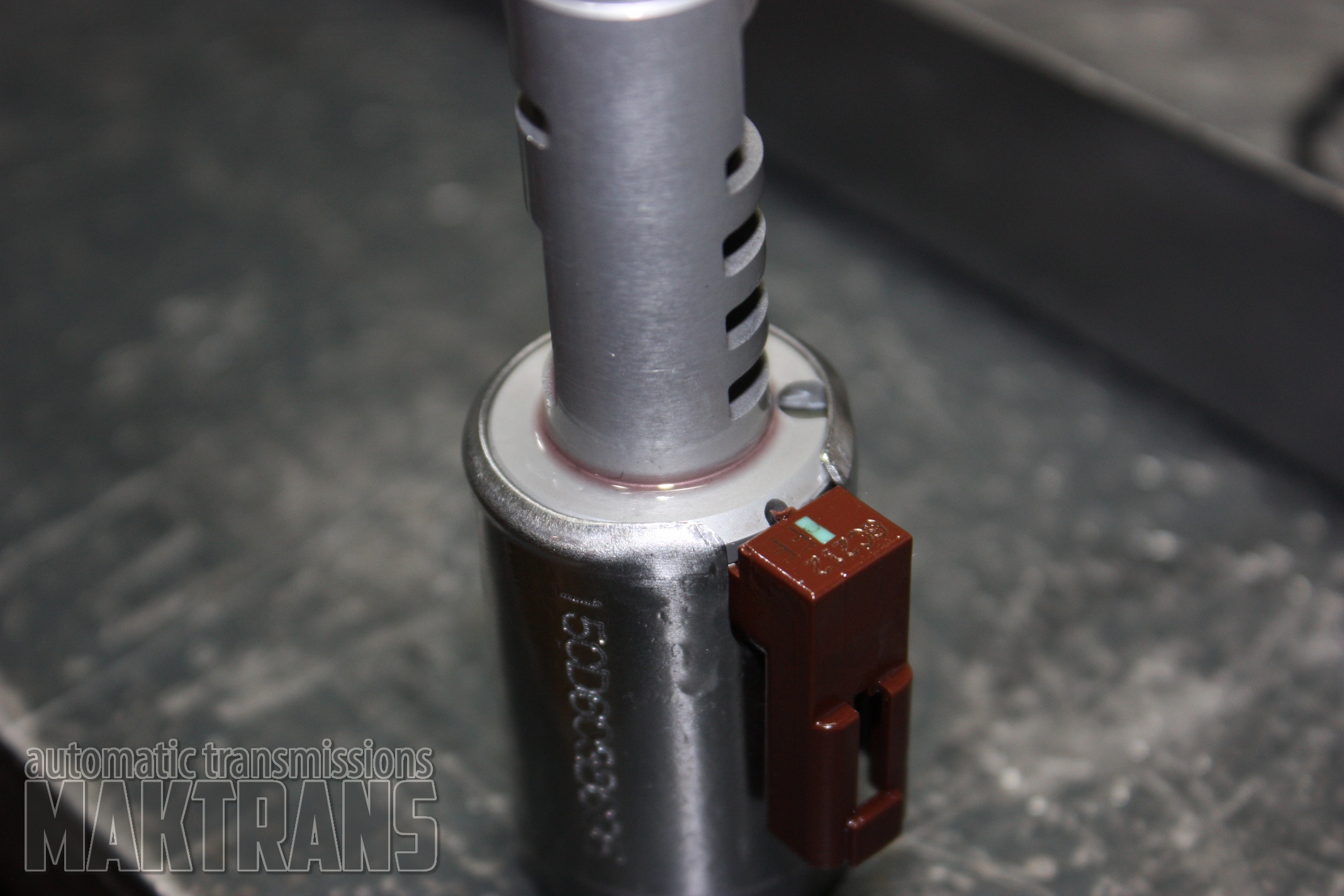

Fixing the case and opening it

|

|

Usually in solenoids of this design, the main culprit of the problem is dirt, which leads to jamming when solid particles enter between the plunger and the guide bush. It is often sufficient to thoroughly wash and polish the work surfaces. If the owner of the car does not immediately turn to the service, but continues to operate the car after the appearance of symptoms - wear may appear on the hub and replacement will be necessary.

After cleaning and (if necessary) replacement of the bushing, the solenoid is assembled and closed using a press.

|

|

|

Again, we test it at the stand, since in theory the situation is possible when the geometry of the plunger surfaces is broken and the solenoid will still work poorly:

The graph is good, the solenoid can be installed in the valvebody

It is over with the solenoids, the rest of the solenoids are checked and regenerated in the same way. We proceed to the next stage.

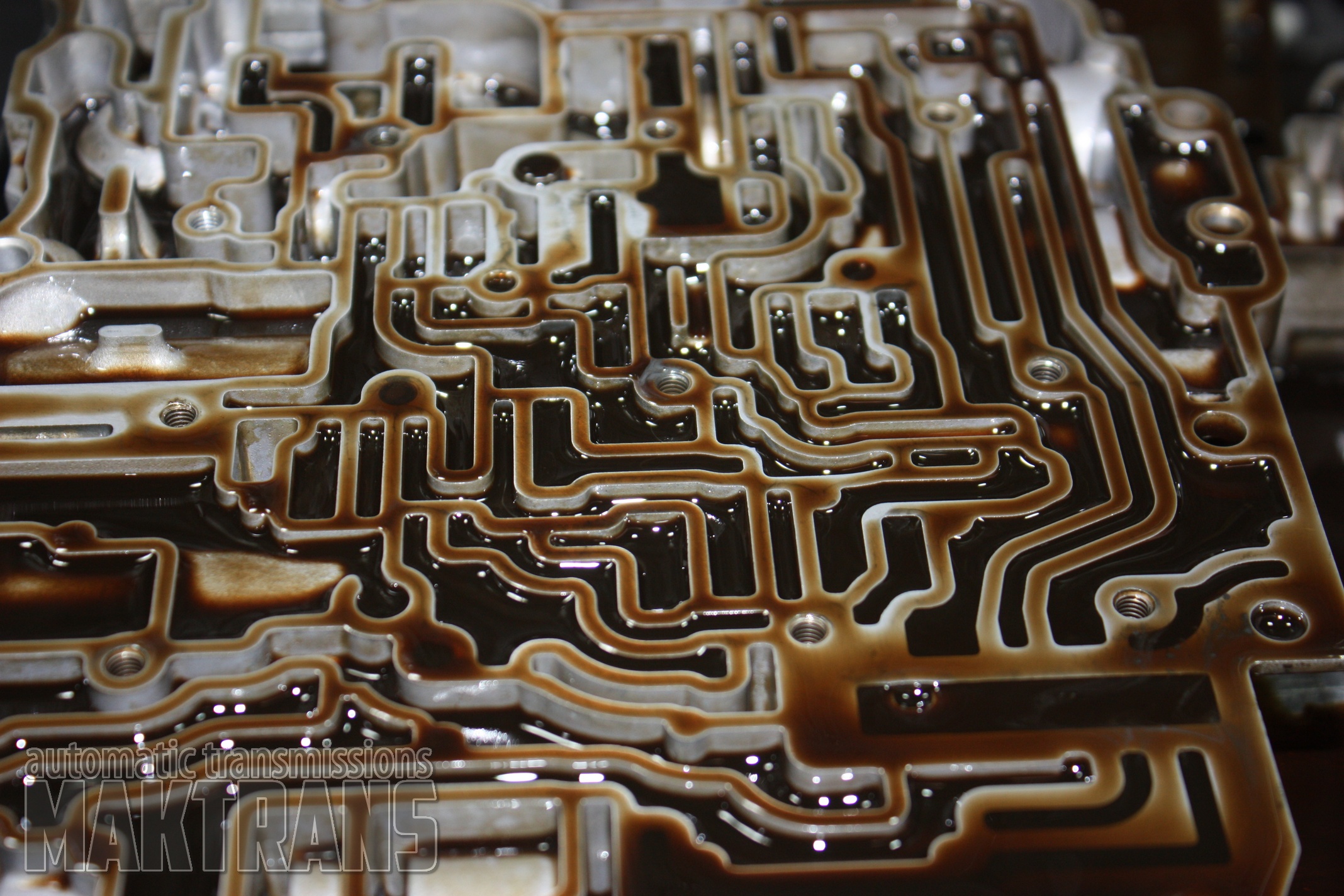

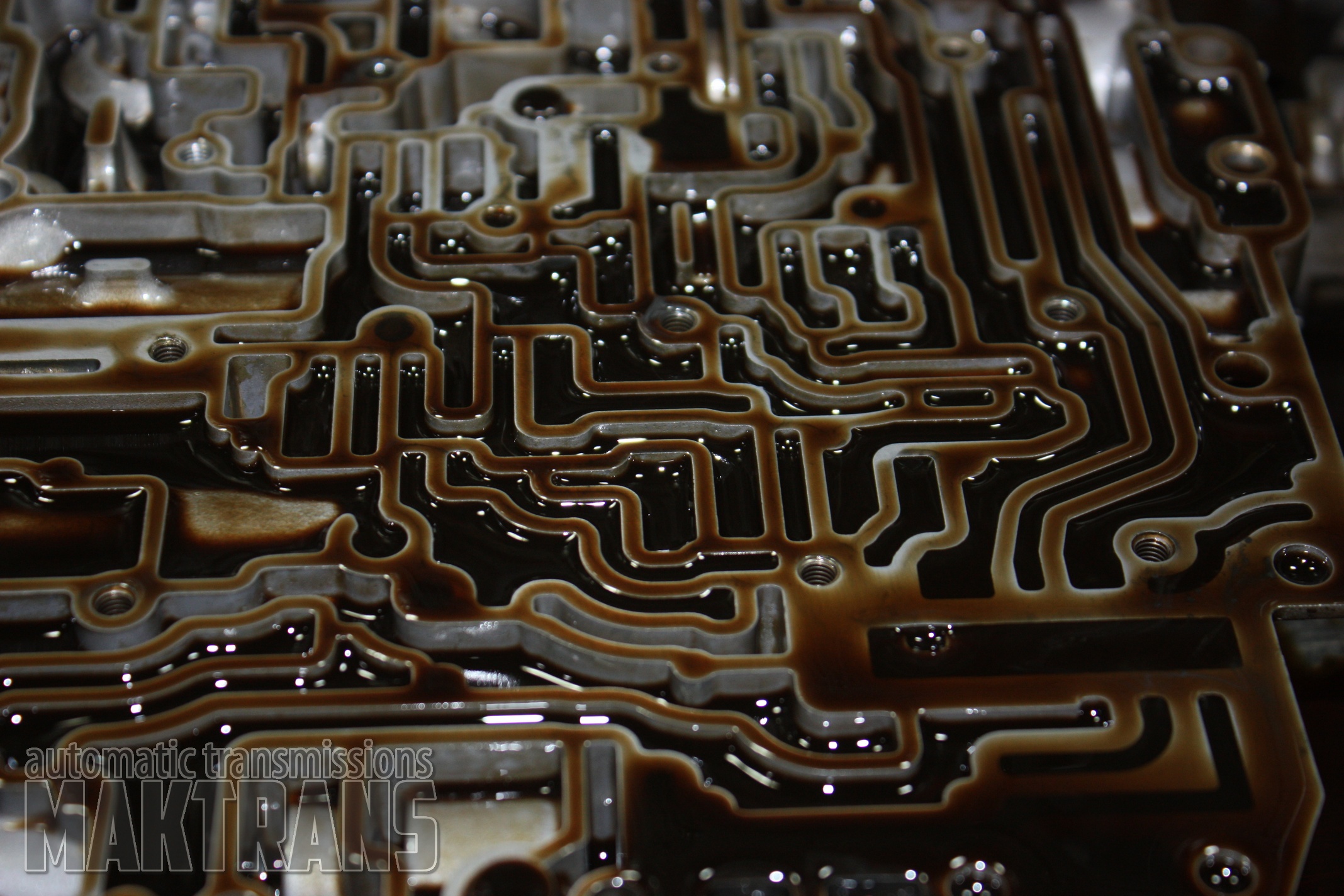

Vacuum testing

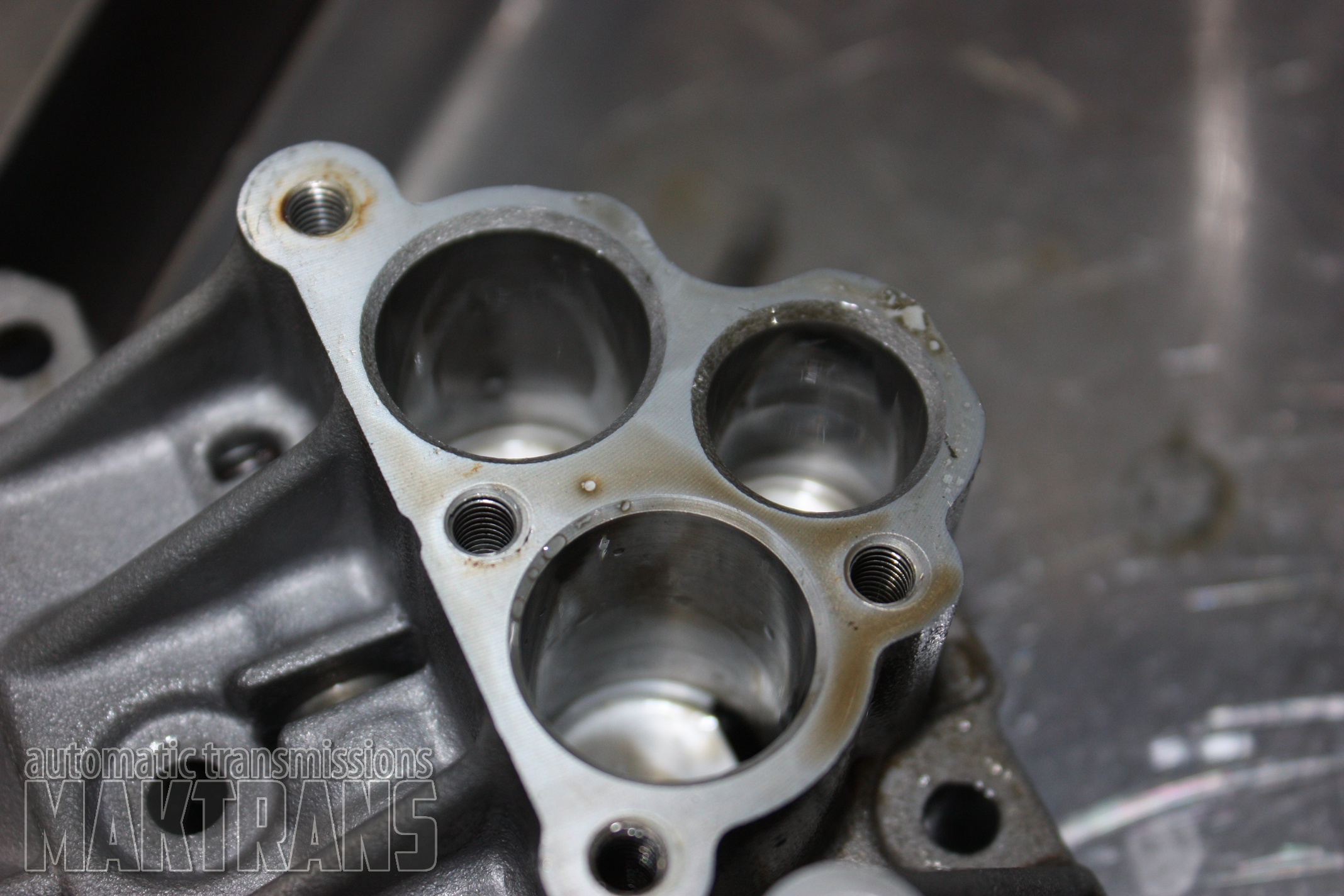

We take clean plates from the washing machine and inspect for the presence of wearout. In addition to visual inspection, each valve is manually checked for jamming.

|

|

|

|

This is how the working out in the channel of the hydraulic plate look like

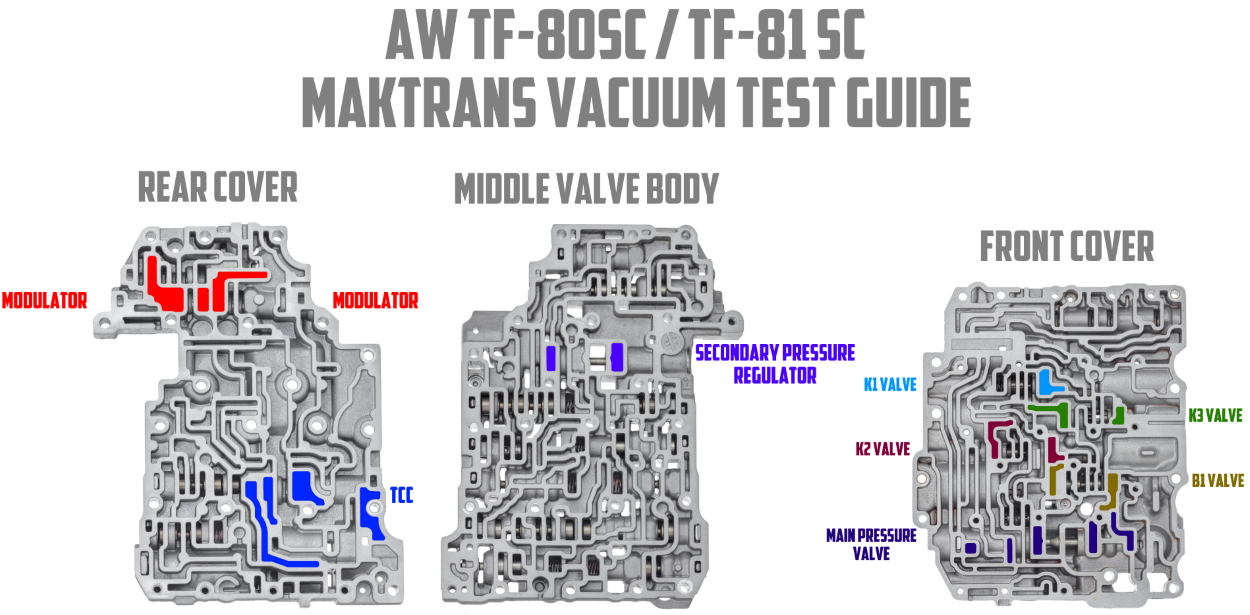

We begin to check the hydraulic part for leaks. To do this, you will need a vacuum tester and a diagram that shows the zones of the water plate that you need to check. Experienced masters do this from memory, but beginners will need the instruction below. It is interactive, after determining the faulty plunger / channel, you can click on its name and go directly to the product card.

We begin vacuumizing.

Vacuuming indicated problems with the following plungers which will be replaced for oversized ones:

- Oversized K2 Clutch Control Valve AW TF-80SC TF-81SC

- Oversized K3 Clutch Control Valve AW TF-80SC TF-81SC

- TCC Lock up oversized solenoid kit AW TF-80SC gen2 (TF-70SC) AW TR-60SN 09D

- Oversized Solenoid Modulator Valve Kit AW TF-81SC

- Acumulators

The master marks the channels that need to be deployed and transmitted to the lathe. For drilling holes in hydraulic plates, we use a machine that meets several important requirements:

1. Convenient installation of any part, whether it is a small upper 09G plate in which the locking plunger works, or the massive hub of the variator JF010 pump.

2. Supply of emulsion for cooling and lubrication.

3. Ability to adjust the sweep speed. Different channels in different valvebodies need to be deployed at different speeds to obtain a high quality work surface.

Cutting

After reaming, the plates are sent back to the washing machine, you need to get rid of chips, which inevitably stays inside. We wash and blow with compressed air and then we can proceed to a second vacuumizing.

Vacuumizing, the result is good

We have already restored solenoids and hydraulic plates with installed increased valves and then we collect valvebody.

The assembled valvebody will be checked on the stand . This stand is essentially an automatic transmission simulator, it includes a pump that generates the same pressure as the oil pump of the box, the sensors for monitoring all operating parameters and the electronics that control the valvebody. The valve block is installed through the adapter plate, wiring is connected to the solenoids and sensors.

We expose the plates with a guide, fix the clamps, turn on the cooling

Testing

On the monitor, the master sees 2 graphs that in real time show 2 main parameters:

1. Top graph - shows the work of each solenoid separately;

2. Bottom graph - the parameters of the hydraulic part. Assuming that an error was made during the assembly, or some plunger jammed during operation, it will immediately be visible.

If the valvebody has passed the test, we pack and ship it to the client. Typically, the recovery procedure for the valvebody AW TF-80/81 is part of the AT overhaul o, so we immediately give universal recommendations:

1. The cooling system is a very important point, which many masters forget, or do not pay due attention. Any design containing a hydraulic circuit, especially such a high-tech as an automatic box, is extremely fastidious to the quality and purity of the oil, which means that we need to make sure that the system is clean. For this, heat exchangers, radiators, thermostats, all pipes are washed or changed, the torque converter is necessarily cut.

2. Oil. Be sure to fill in a new one, according to the tolerances DEXRON VI is suitable. We use the FUCHS TITAN ATF 6000SL. The filter changes when the box is completely disassembled, there are 2 types - a filter element, either mesh or paper. We recommend paper one.

If you comply to all these recommendations - problems after installing the regenerated valvebody will not appear.

In addition to the valvebody, the AW TF-80SC has other problems. The all-wheel-drive Mazda CX-7, Mazda CX-9 and Hyundai Veracruz have a constructive drawback - moisture gets between the box and the distributor, which leads to corrosion and fracture of the spline in the differential, we offer B-D differentials, splined part in very good condition.

If you need other parts for repair, you can see and order here:

• Parts catalog AW TF-80SC AW TF-81SC (AF40 AF4)

Payment

- PayPal (Payment to a PayPal account, without obtaining European VAT documents)

- Bank Transfer P2P only (Payment for private banking account, without the possibility of obtaining European VAT documents)

- Crypto Payment (If you want to make payment in cryptocurrency, without the possibility of obtaining European VAT documents)

- B2B sale with VAT ID: no VAT is charged (When buying for more than 300 euros, B2B sale with VAT IDfor countries VIES: no VAT is charged (With mandatory indication of the European VAT number and receipt of documents for the company) when buying for more than 300 euros

Shipping

We work with shipping companies like DPD, DHL, FedEx and we can ship worldwide. Shipping cost you can see during checkout and on product page (you can use button "Shipping Cost Calculator")

Hello, i have a Volvo xc90 D5 engine from 2006, the car needs a valve body replacement , how much will cost to buy from you a valve body? New or refurbished. I have the 6 speed auto. Thank you.

MAKTRANS

MAKTRANSHello, we can repair your valve body, price around ~400 USD.

Hello, I have a bva AM6 on my Citroën C6. The second speed slip. There is a problème with Valve B1. How did it cost for repaire this désorder with send ? Thanks Cordialy.

MAKTRANS

MAKTRANSHello, total repair cost around 400 euro.