$0.00

Checkout- Brand: MAKTRANS-VB

- Product Code: A750960VBREBUILD

Product model copied to clipboard

- Weight (kg): 10

- Availability: 19993

| Stock Place: | Availability: | Qty: |

| Poland | 9998 pcs. |

|

| Ukraine | 9995 pcs. |

|

- Product overview

- Shipping & Payment

- Questions - Answers (2)

- Related products (14)

A750E / F (marking F stands for four-wheel drive) is a popular 5-speed automatic transmission manufactured by Toyota, since 2002 it began to be mounted on the rear and all-wheel drive Lexus GS470 / LX470 and Toyota HILUX / Land Cruiser / 4 Runner with engines from 2.5 to 4.7 liters. The box was not accidentally massively installed on expensive Lexus cars, at the time of its appearance it was an advanced and reliable 5-speed automatic transmission that without any problems maintained 150-200 thousand km. run without the need for repair.

A little later, in 2005, the A760E / H and A761E / H transmissions appeared. These are already 6-speed units, however they are designed on the basis of the A750 and are structurally very similar. The A760 series became very popular and in addition to Toyota / Lexus and other manufacturers began to install these boxes, the A760 can be found on Hyundai Genesis, Jeep Liberty and even on Renault Master.

The next round of evolution of Toyota's 6 speed is the A960E and AB60E. A960E is a lightweight version of the A760E and is designed to work in tandem with 2.5-3 liter engines, the torque limit is 300 Nm. Installed on Lexus IS250, IS300, GS300 and Toyota Mark X. AB60E is a reinforced version of the box, can be found on Lexus LX570 and Toyota Tundra, Sequoia and Land Cruiser with powerful V8 5.7L engines

All these transmissions have many common features, since they are designed on the same base according to the modular principle, but in this article we will consider the repair of the valvebody (transmission control unit). The A750 / A760 / A960 / AB60 valvebodies are not interchangeable, but the repair will look the same for any unit in this series, since the mechanics of operation are the same and parts such as valves and solenoids are also compatible.

Before proceeding with the repair, we’ll tell you about the pricing of the service. The cost of repair at Maktrans is not fixed and consists of 2 components, the cost of work and the cost of consumables. The table below shows the calculation of a typical A960E valve body repair:

| Works | Price |

|---|---|

| Diagnosis (disassembly, washing, vacuum testing, visual inspection and inspection of plungers for jamming) | 100$ |

| Testing solenoids on the stand and repair ( 4 solenoids are being repaired, price for repiaring of one solenoid - 40 $) | 160$ |

| Reaming valve body channels and installing oversized valves. Reaming of one hole is - 20$, plunger - 10-20$. | 70$ |

| Assembly and final inspection | Free of charge |

| Total: | 330$ |

If you don’t delay the repair, you will get the valve body restored to the factory state and a 1-year warranty with no mileage limit for only $ 330.

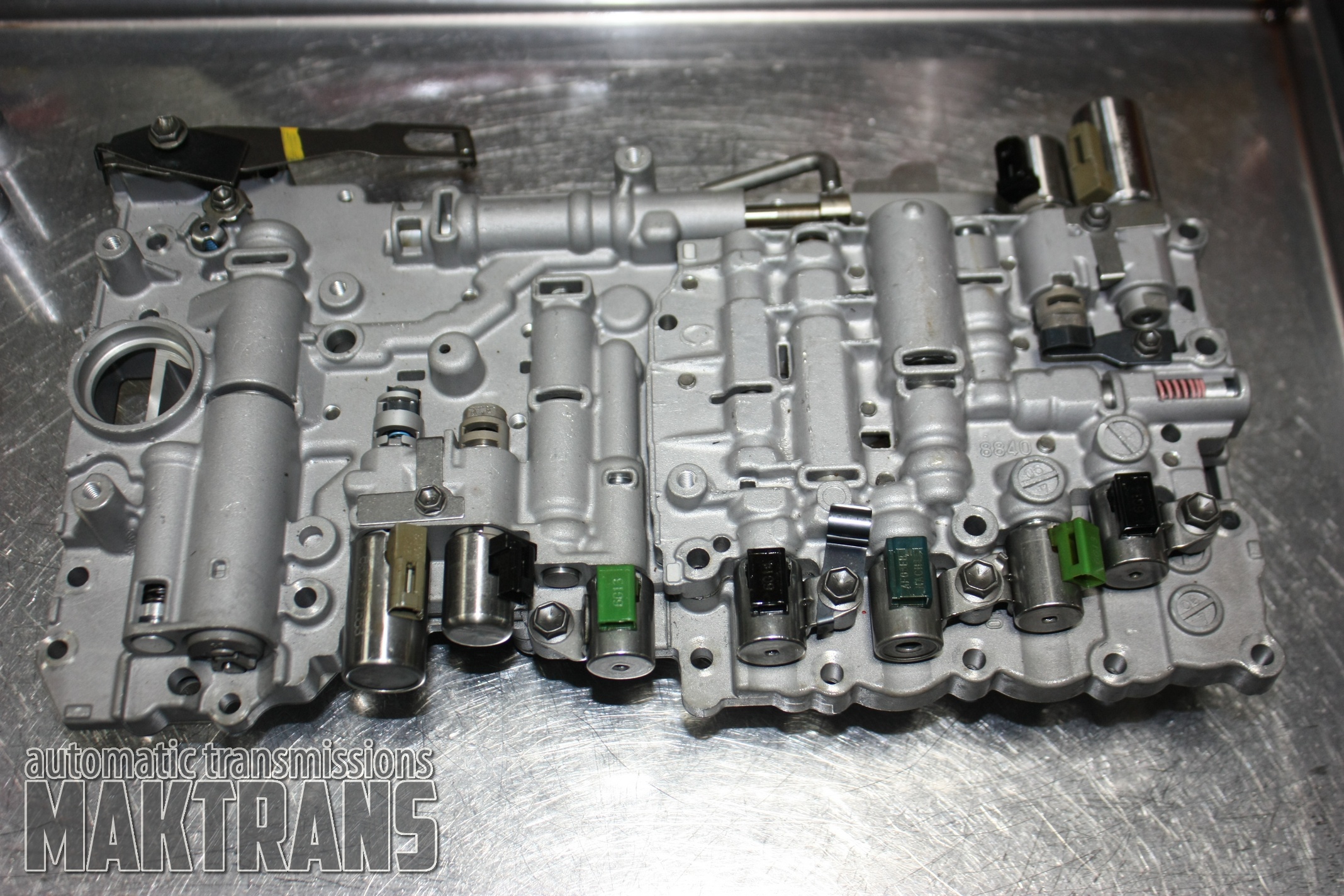

Beginning of the repair. Disassebly.

We have a valve body from the A960E box, the valve body is being restored for sale, so we don’t have any information about which car it was removed from and what symptoms it was while driving, but in general we’ll tell you how the driver can feel problems with the hydraulic control unit. Failures of the valve body can be divided into 2 conditional groups, these are problems with electromagnetic valves (solenoids) and the actual wear of the hydraulics. This leads to the fact that the plungers, whose task is to redirect the flow of oil, can jam in the open or closed position:

- The solenoid plunger jams in the open position - the oil pressure is above normal and there may be thumps and pushes when shifting gears. If the defect is not eliminated, shock loads can damage the mechanical part of the automatic transmission.

- The solenoid plunger jams in the closed position - a sufficient amount of oil does not get into the clutch pack and slippage occurs when switching. Slips cause overheating, which can cause friction plates to burn.

- The development in the channels of the hydraulic plate can cause any of the above symptoms, for example, the wear of the lock-up plunger of the torque converter will lead to the situation that torque converter lock up will occur either with a blow, or vice versa, not completely.

|

|

|

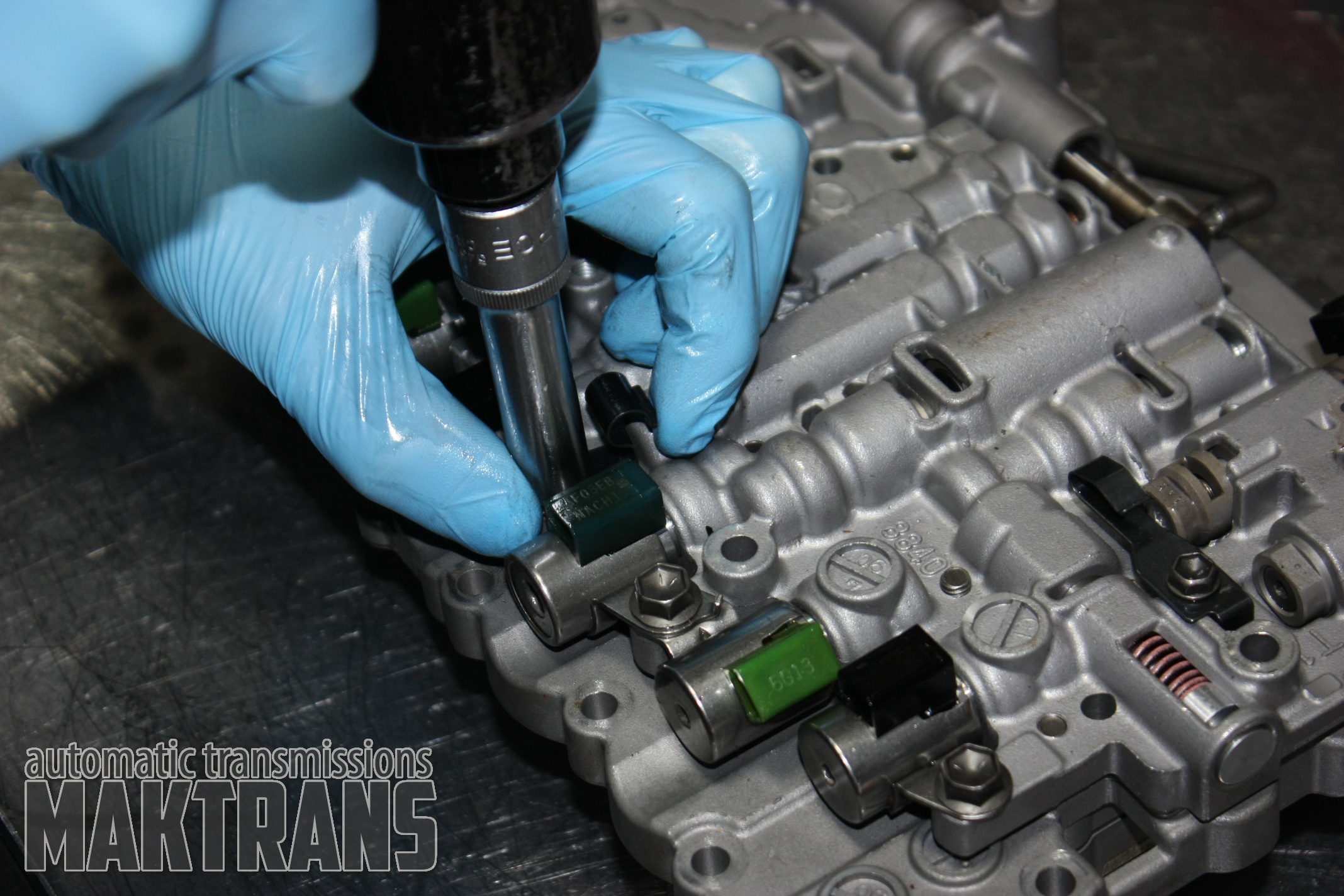

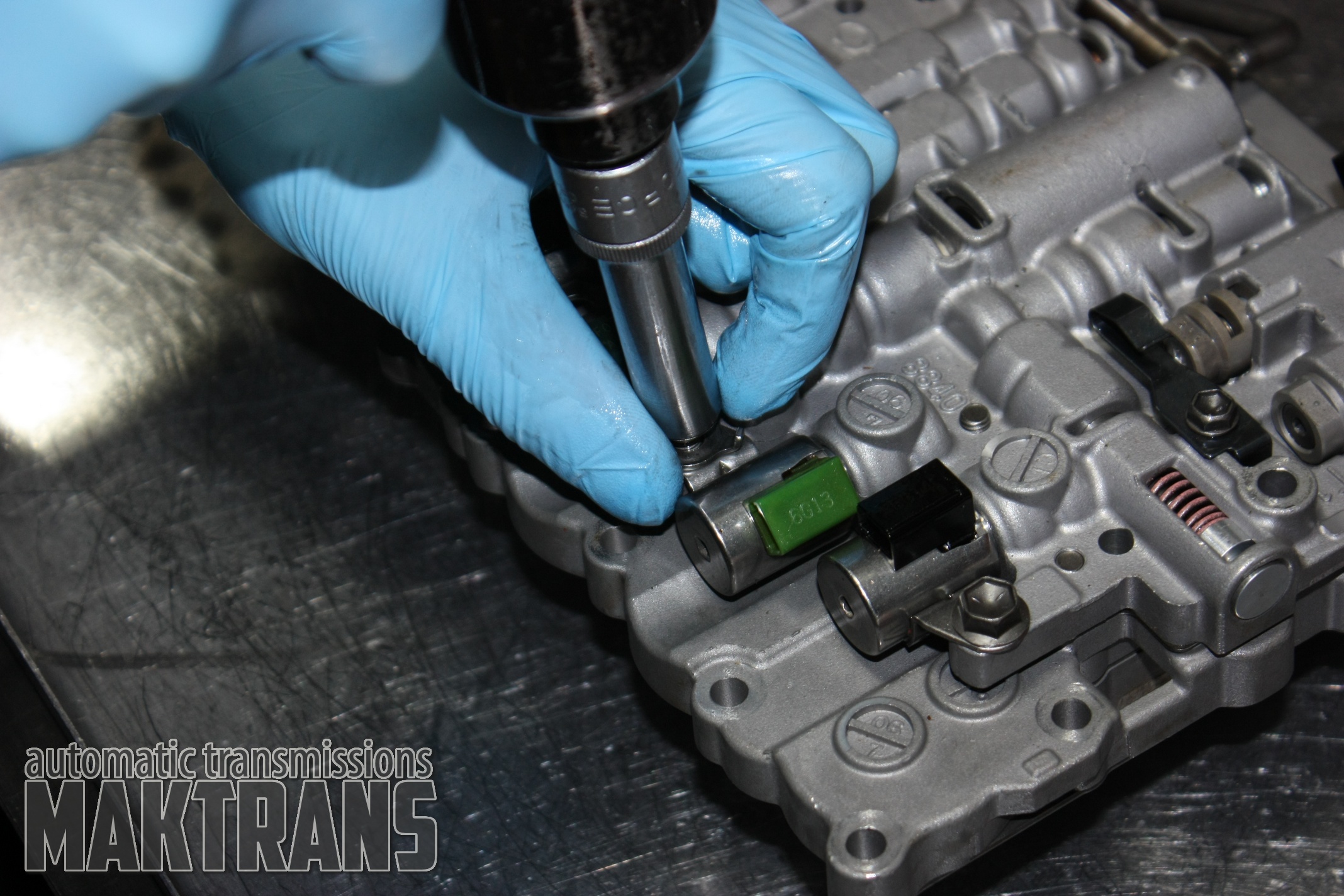

Disassembly. We unscrew and take out solenoids

|

|

|

|

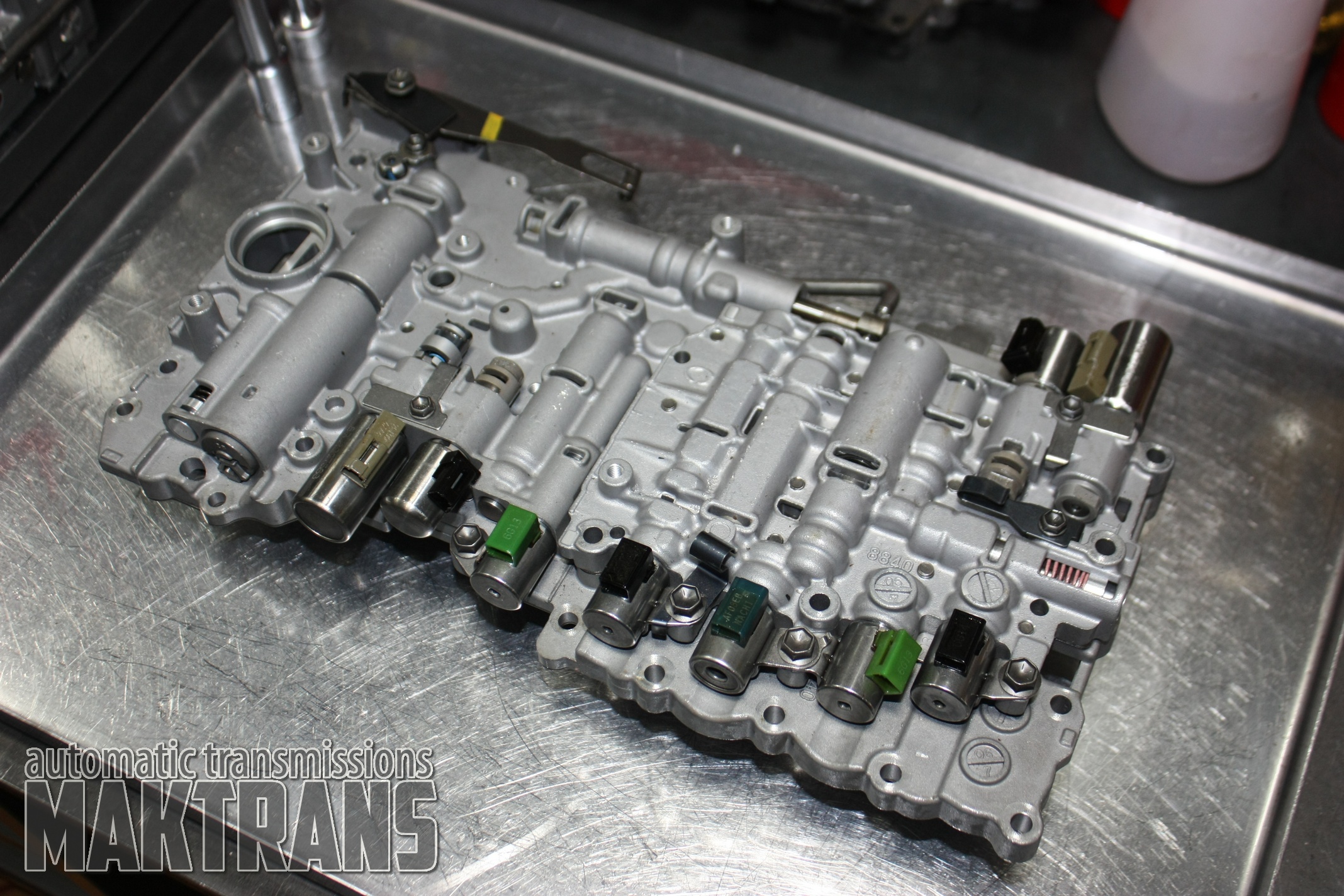

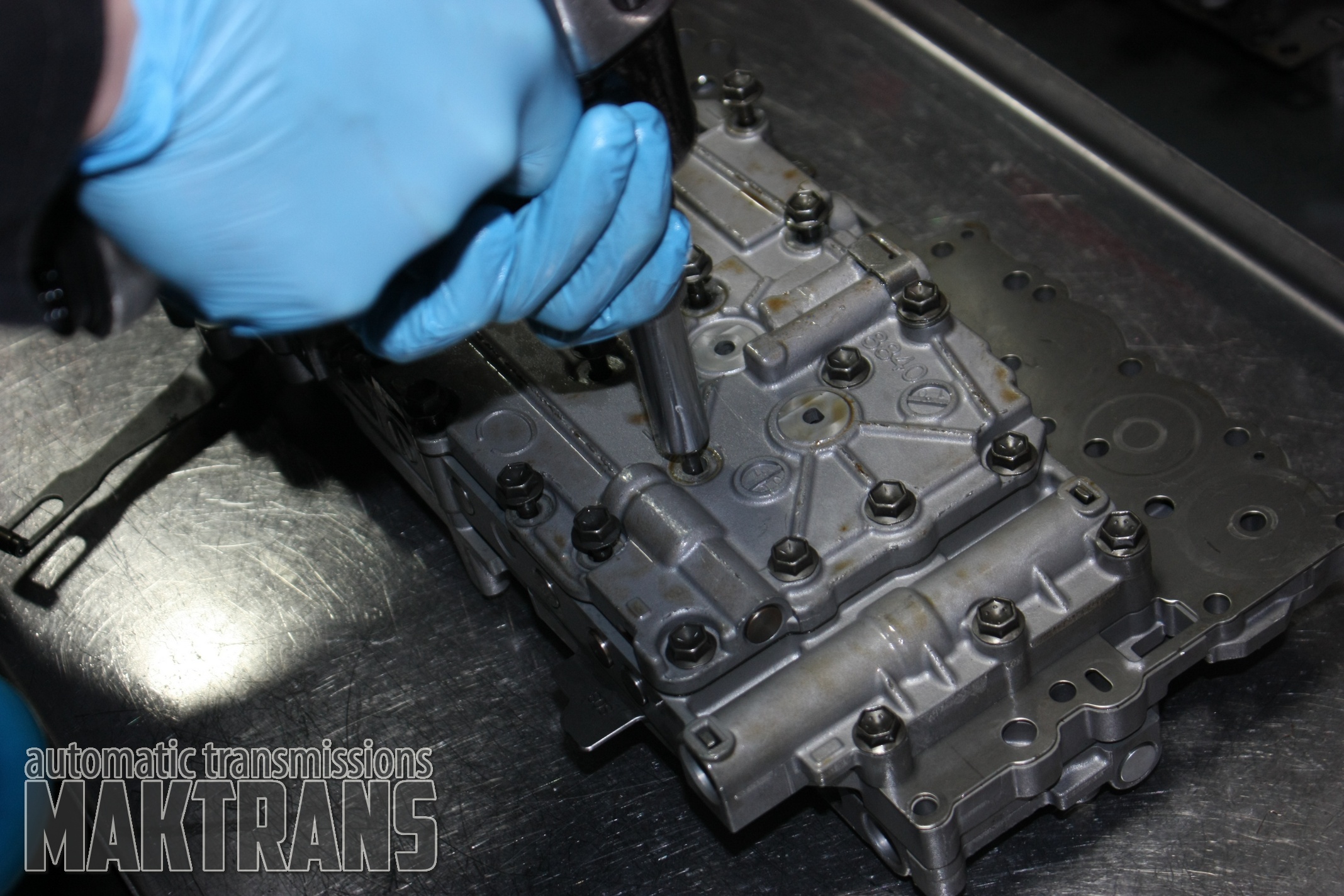

We unscrew the valve body. It will be more convenient to disassemble if the valve body lies in the pallet, since after we disunite the hydraulic plates-balls and springs can spill out

|

|

|

|

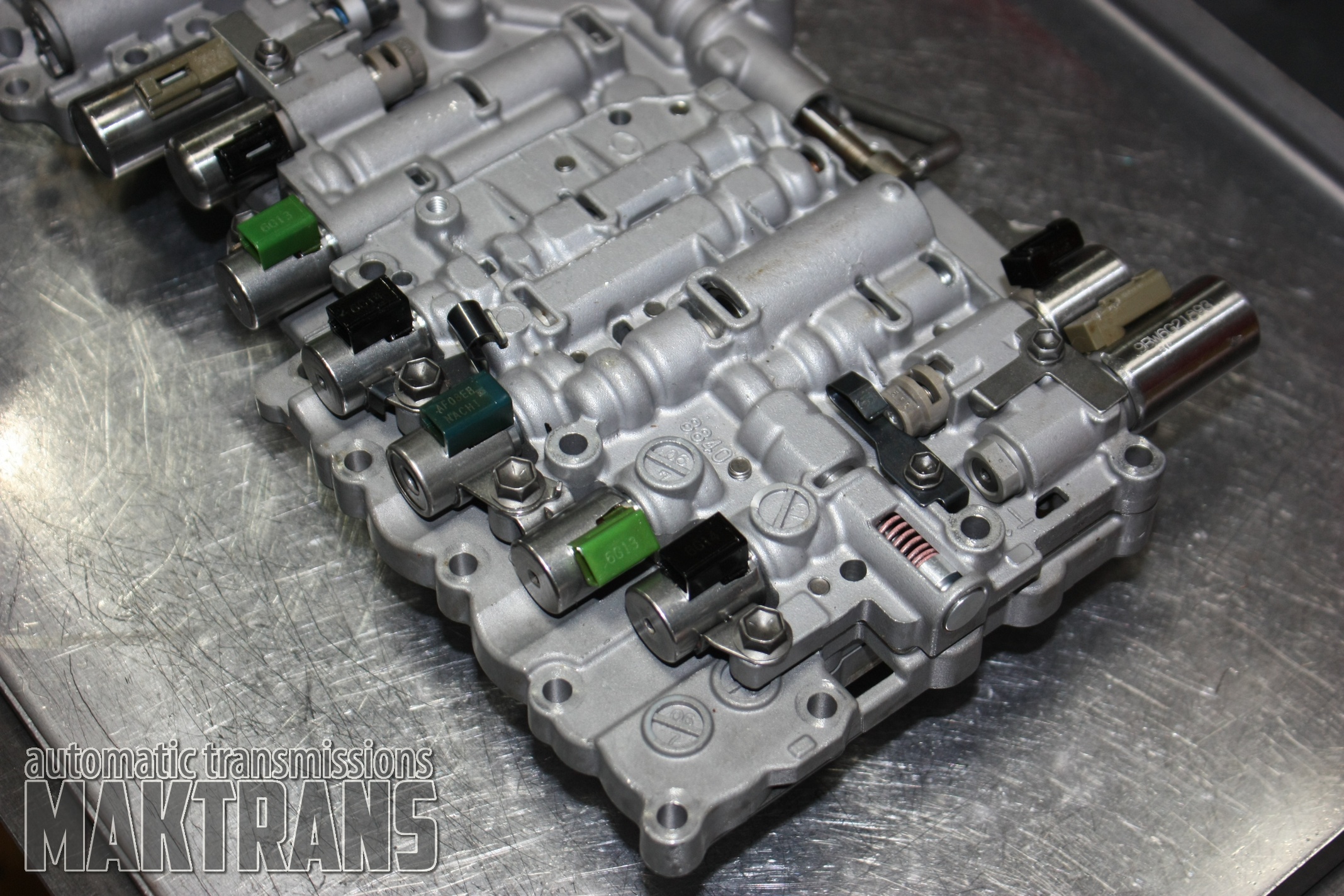

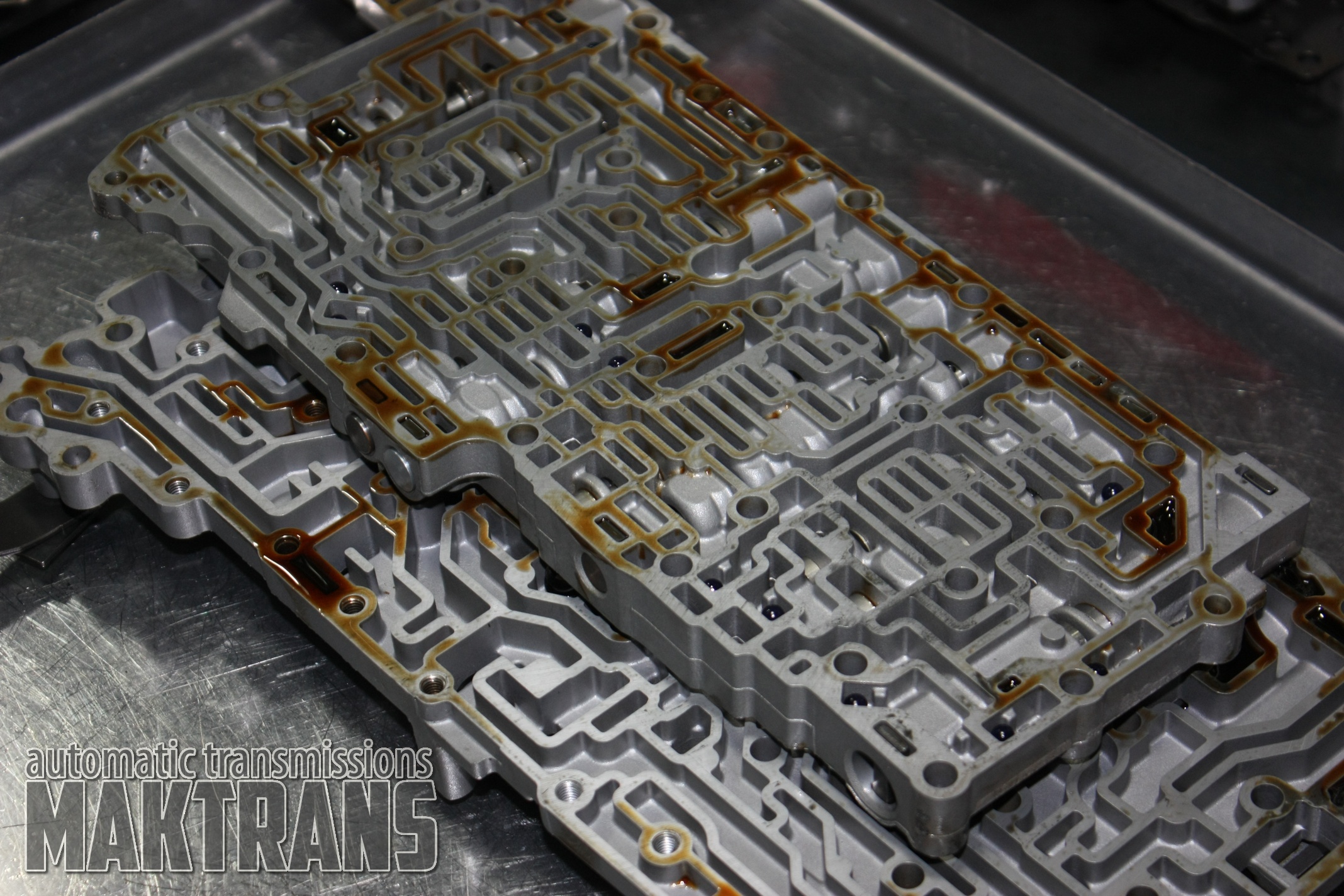

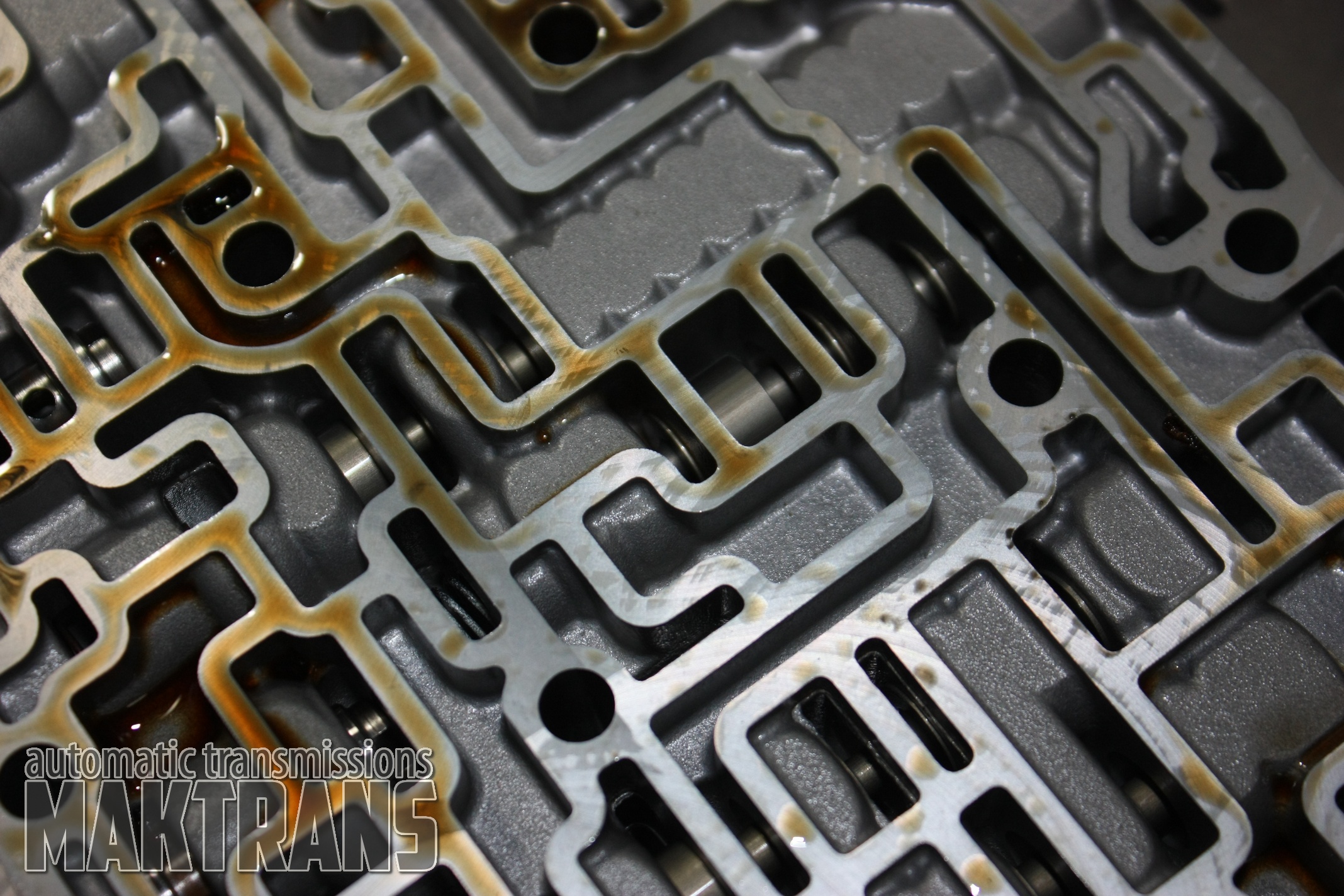

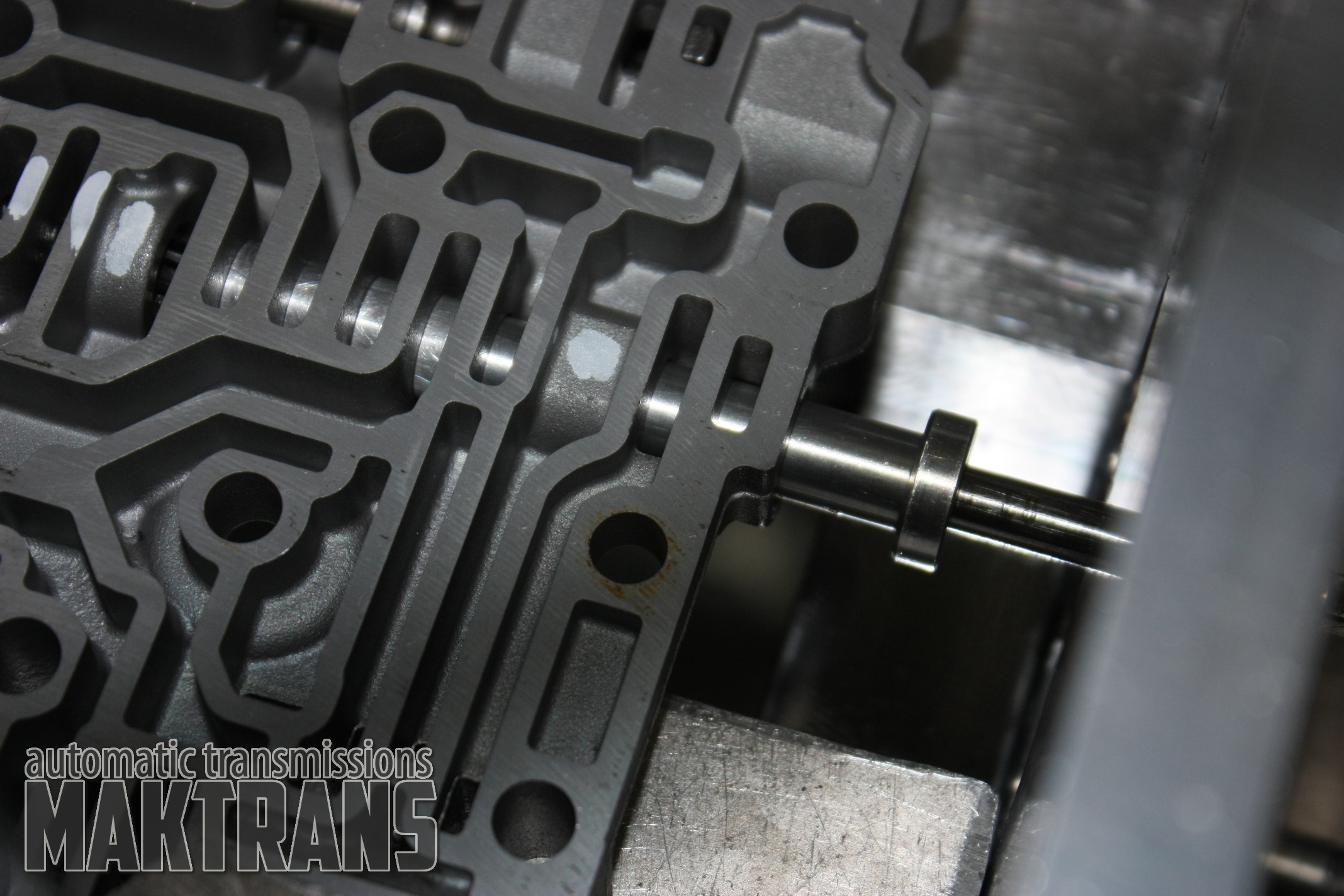

In the photo below there is a weak point of almost all Toyota valve bodies. This plug wears out and oil starts to leak.

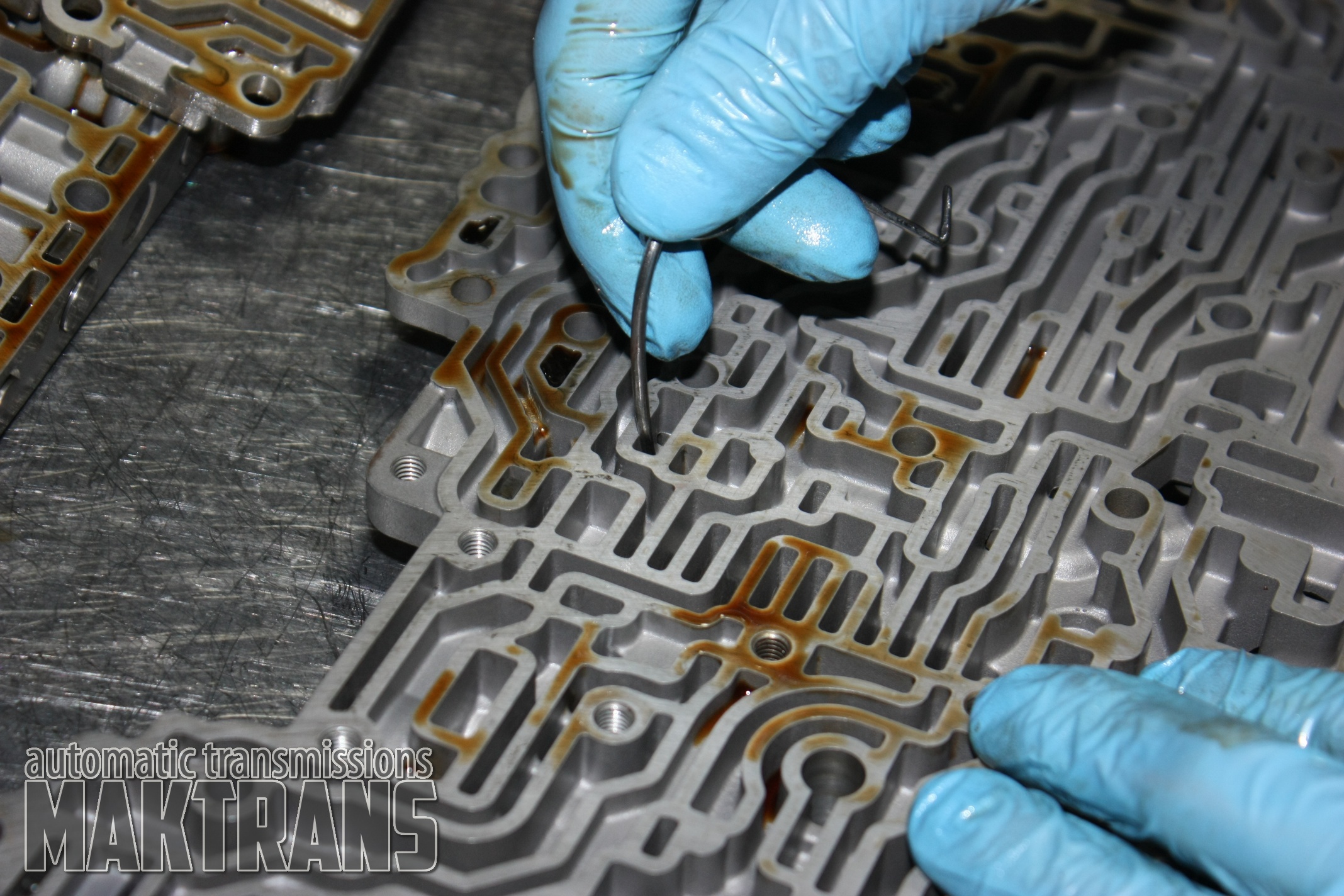

Manually check the valves for jamming, they must move freely in the channel. The method is simple, but it sometimes allows you to diagnose a problem that vacuum testing will not see.

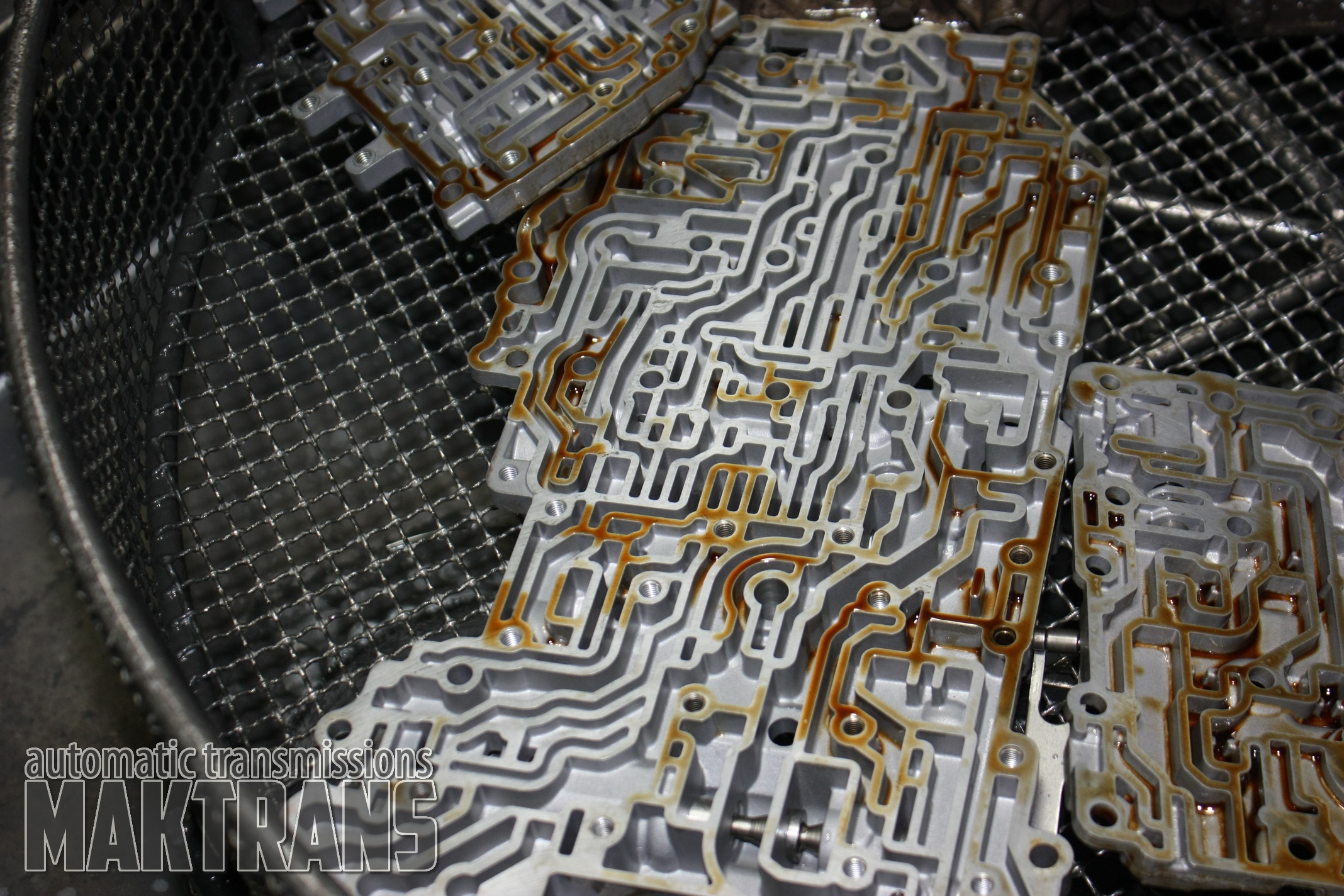

With disassembly and initial inspection finished, we put the plates into the washing machine.

Solenoid checking and repair

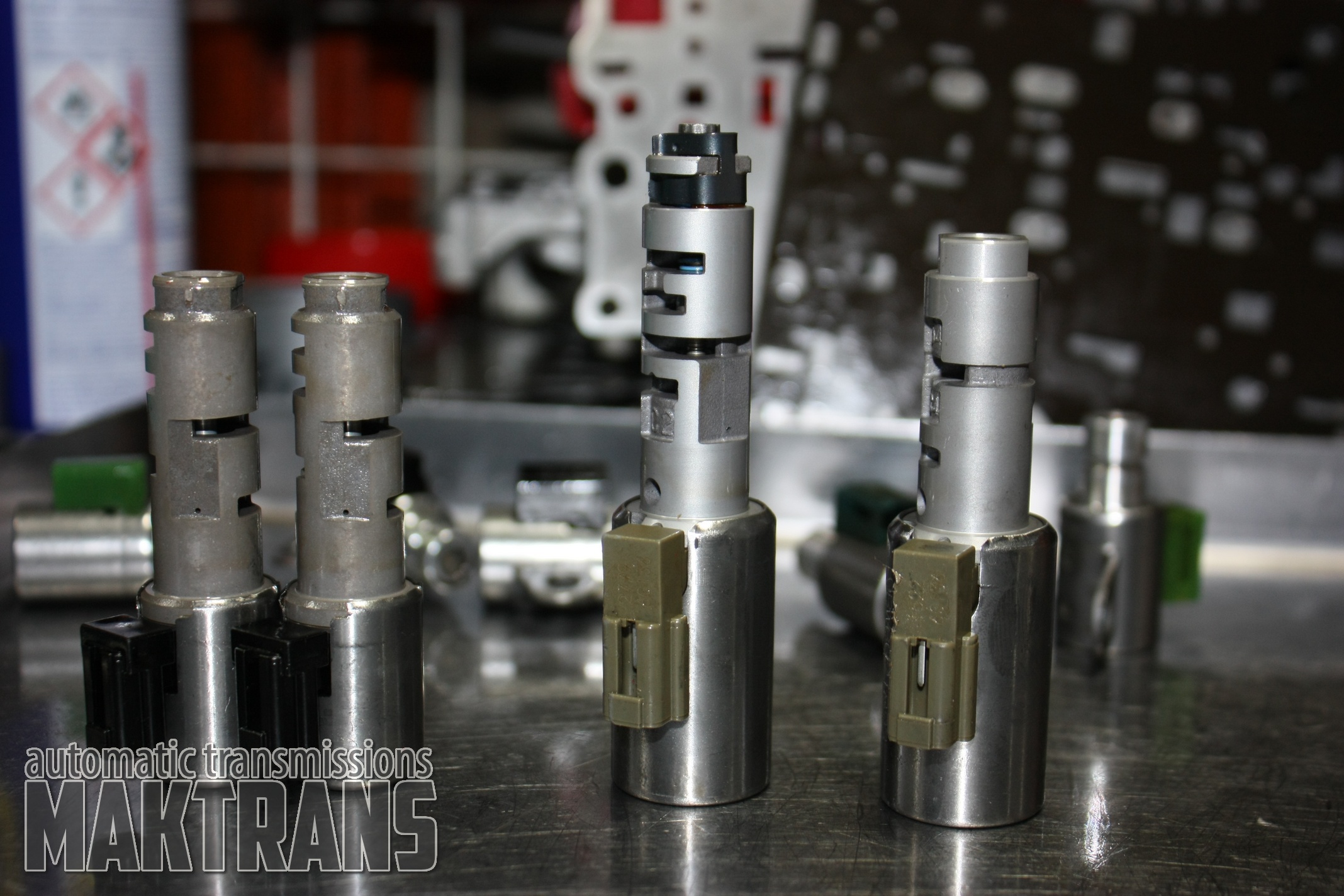

The A960E has 9 solenoids, 4 complex PWM solenoids and 5 ON / OFF's. The latter are not of much interest to us, as a rule they do not break, so it is enough to simply check for resistance and rinse. Let's consider linear solenoids in more detail:

- Solenoids SL1 and SL2, identical and interchangeable

- EPC solenoid (regulates the main pressure)

- TCC solenoid (responsible for torque converter lock up)

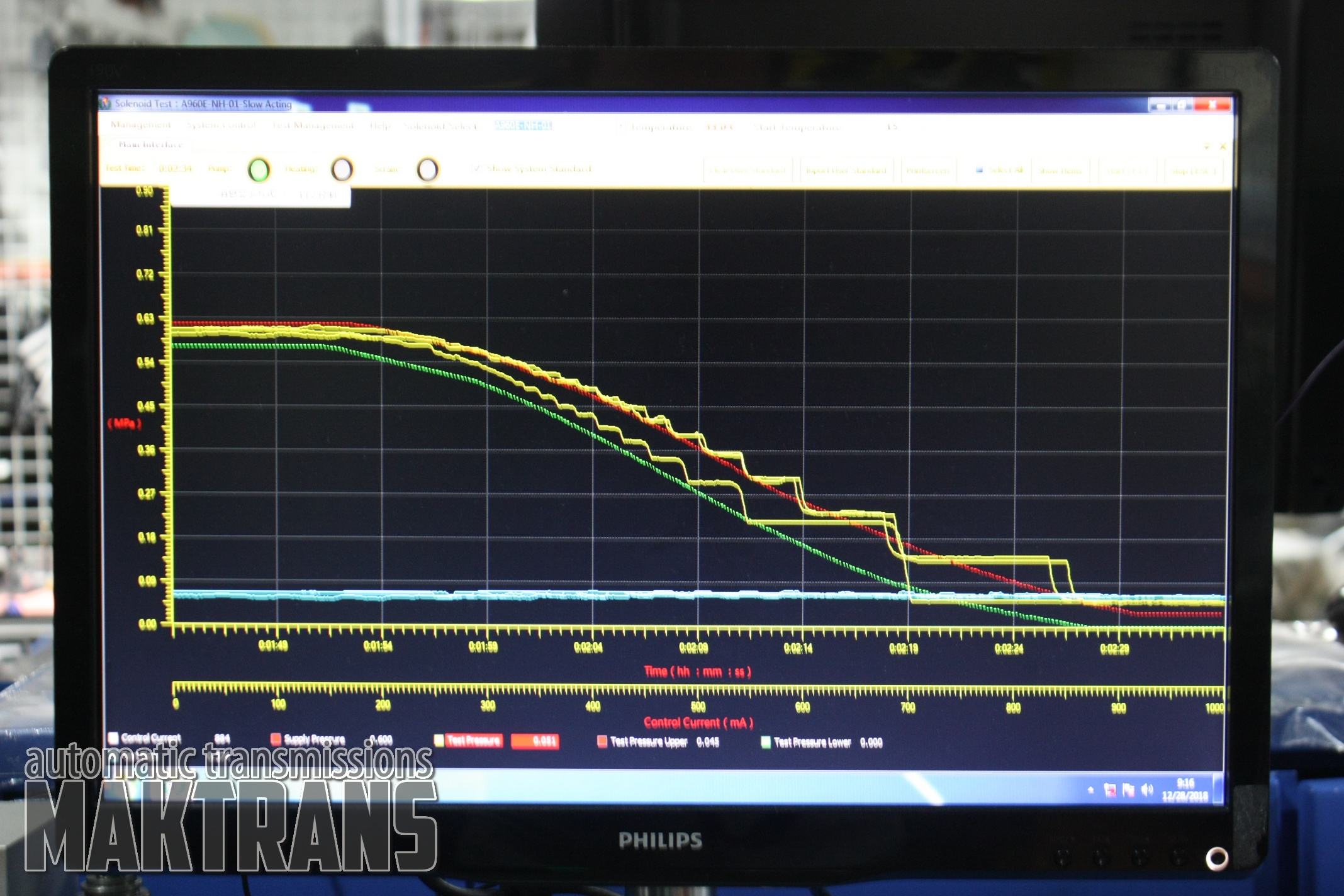

To check the solenoids, we use such a stand - it allows testing the solenoids for operability in different temperature conditions. This is very important in the case of A960E solenoids - almost all show good results on cold, but on hot - problems begin.

We install the solenoid and look at the graph, the steps indicate a stuck of plunger

|

|

The verdict is unambiguous, it needs to be repaired. A960E PWM solenoids are repairable, the repair will consist in disassembling using a special tool, cleaning the solenoid from dirt and replacing the guide sleeves. We show how this happens.

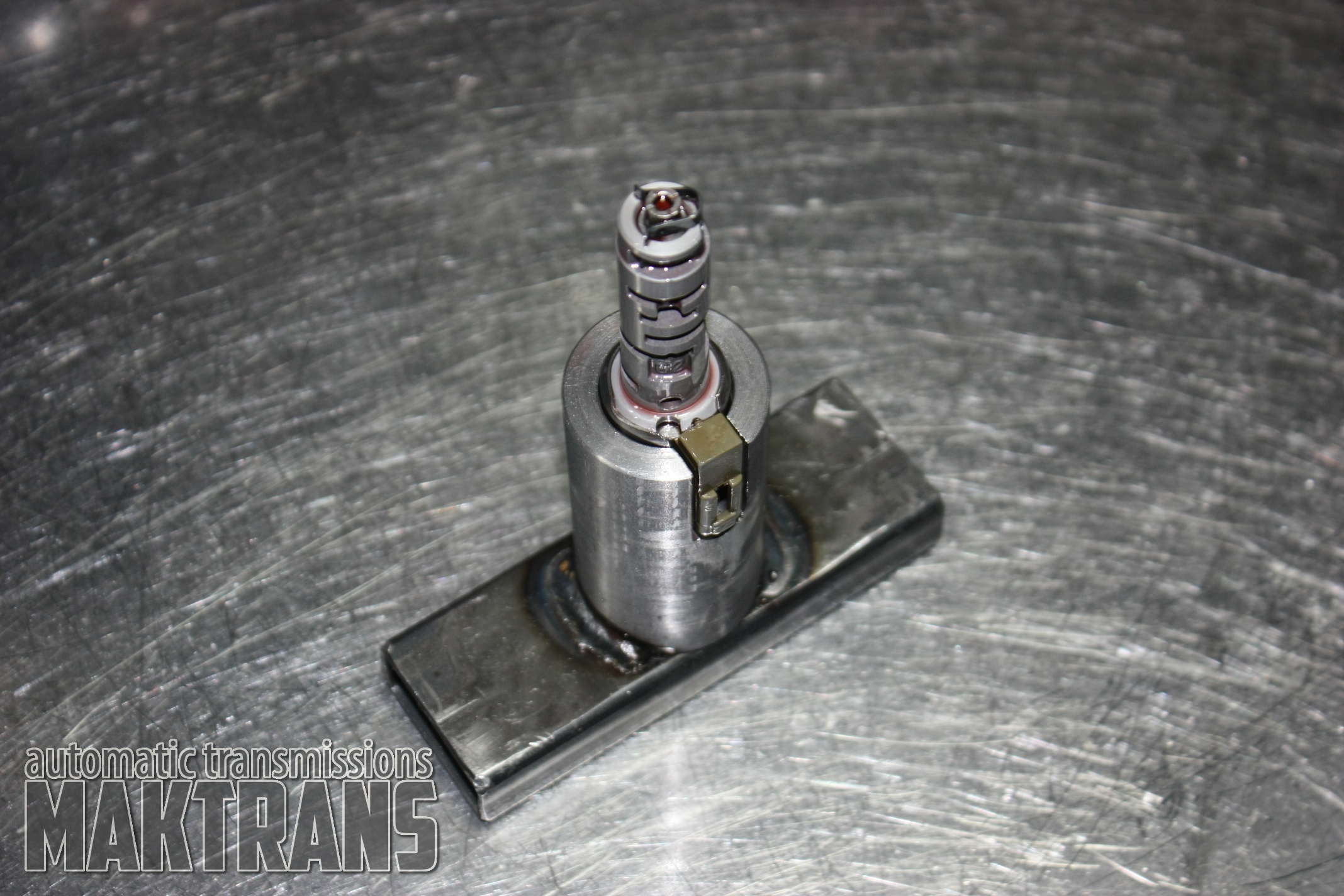

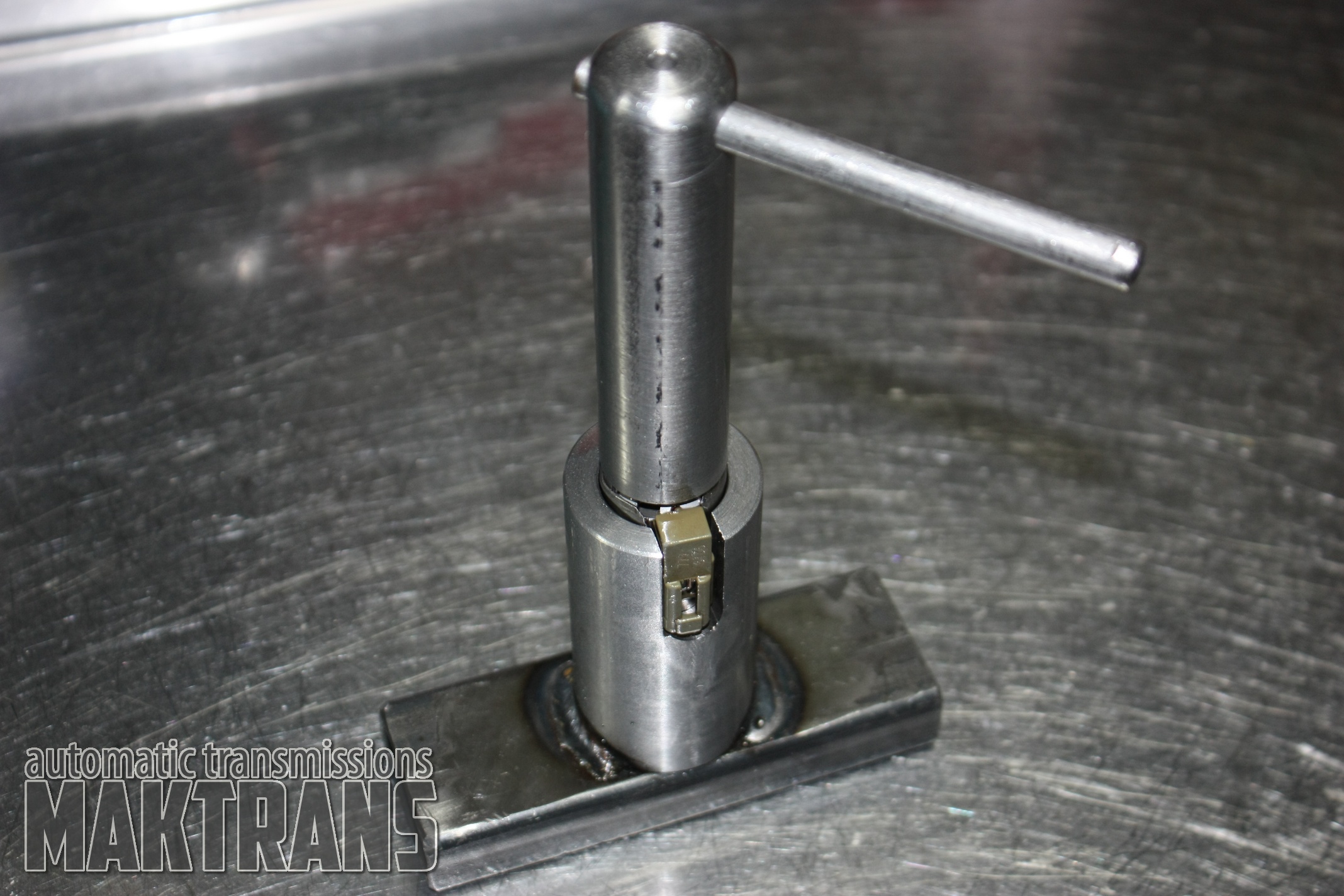

Instaling of solenoid in the mandrel and opening it

|

|

|

|

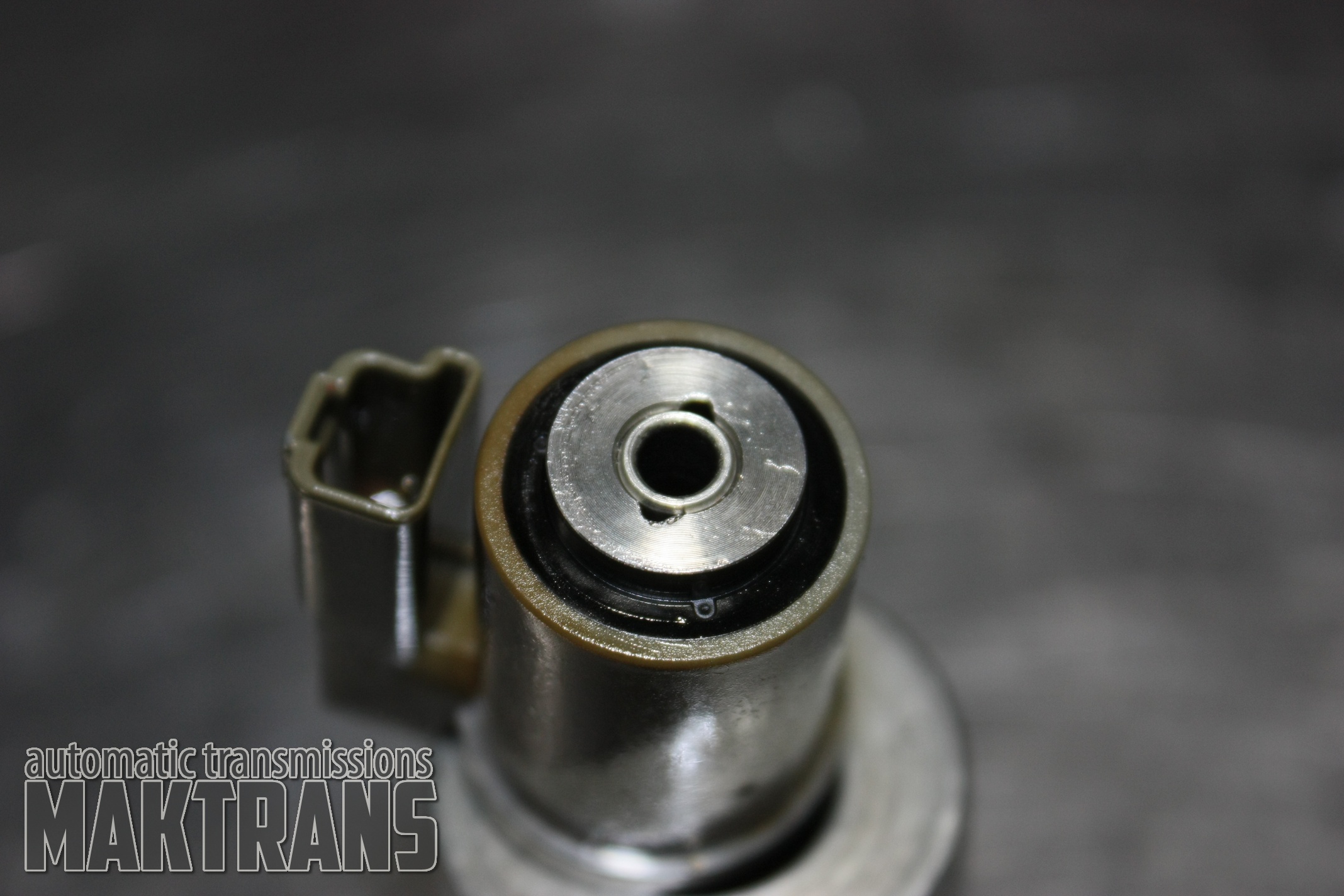

First of all, we are interested in the core of the solenoid, 2 guide bushings are pressed into it. The inner coating of the bushings is polytetrafluoroethylene, it erases with time and the plunger starts to jam during operation.

We take out the bushings and install new ones

|

|

|

|

The solenoid is washed, collected and closed on the press

|

|

Now we explain why replacing the bushings is not possible in "home conditions" - there is an adjusting screw in the solenoid nose, it is not enough just to tighten it. Using the stand and adjusting the screw, each solenoid is adjusted until its characteristics match the new solenoid charakteristics.

|

|

Vacuum testing

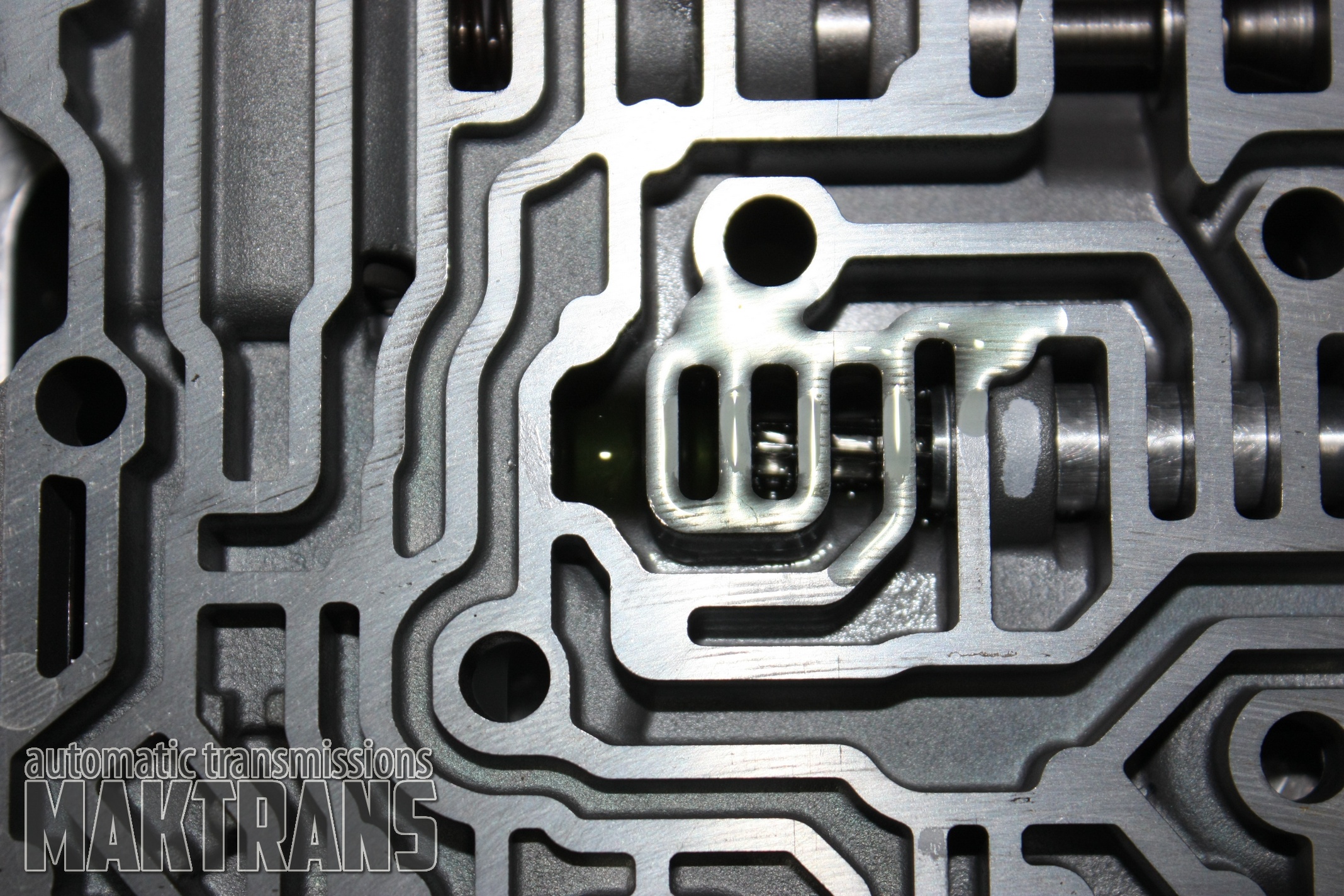

With the solenoids finished, we proceed to the vacuum testing of the valve body. During operation, valve body valve channels are subject to natural wear. The friction of the plunger against the channel walls + dirty hot oil with abrasive impurities eventually lead to the wearout of holes. If the valve body is cut on a milling machine - you can see the following picture:

|

|

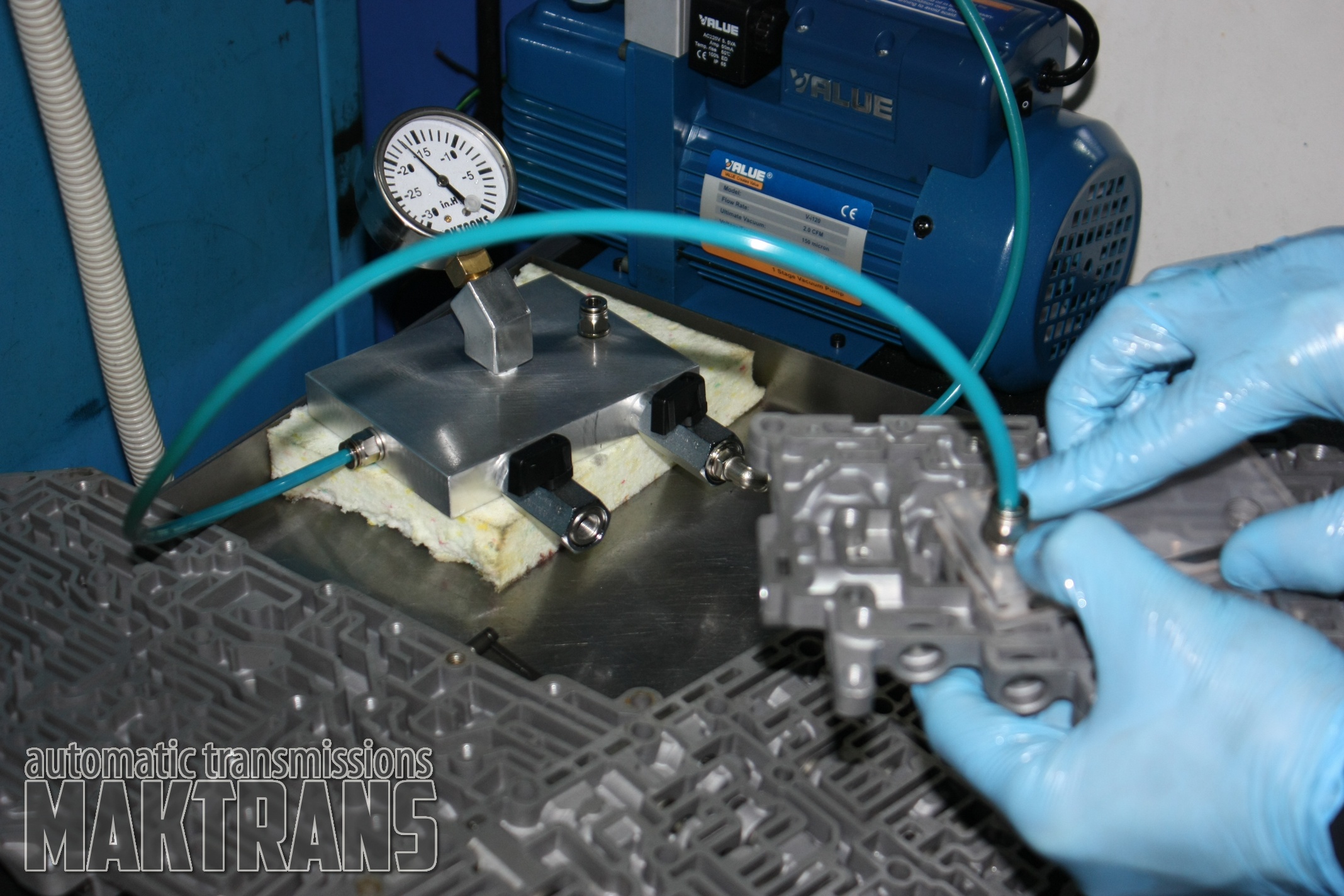

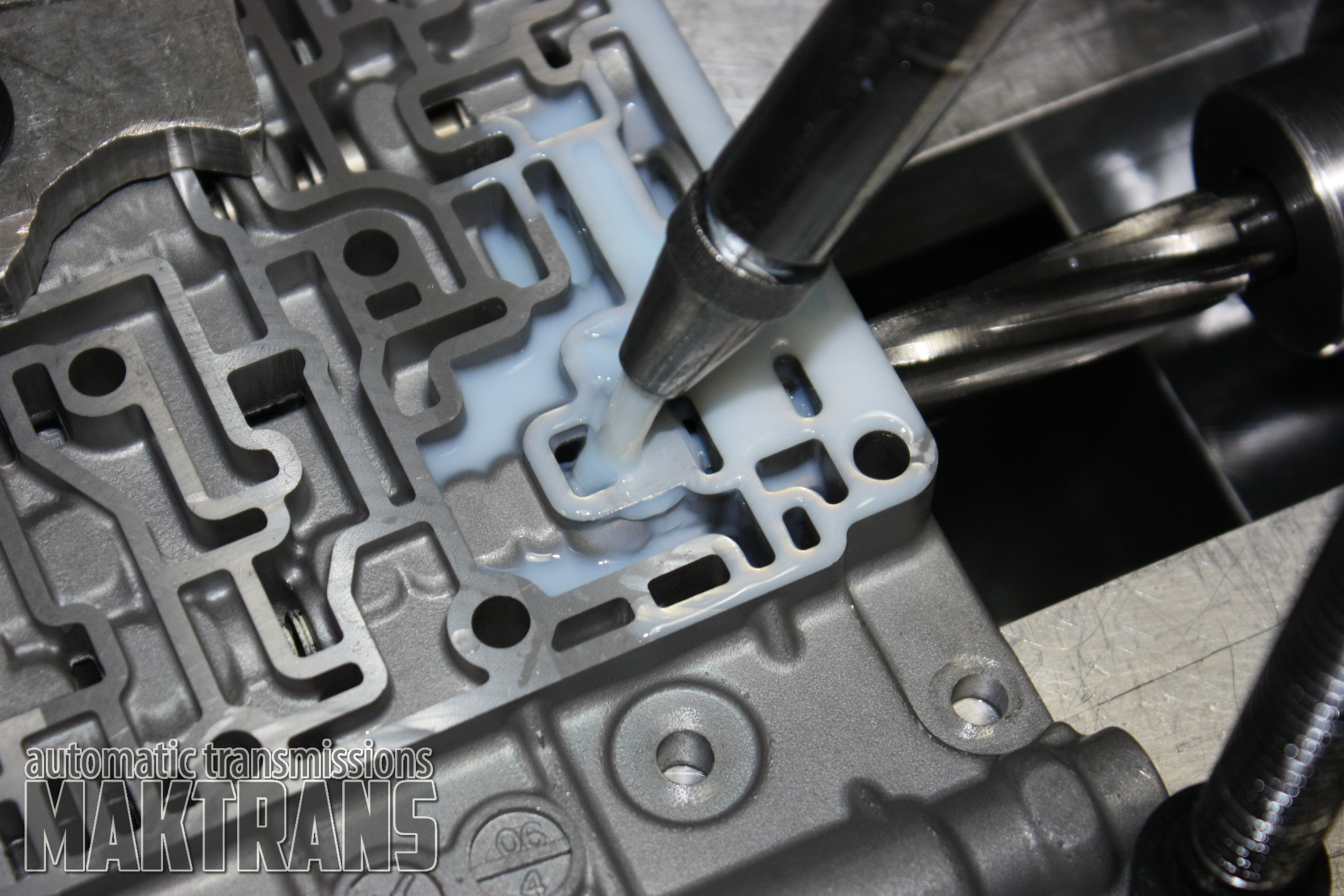

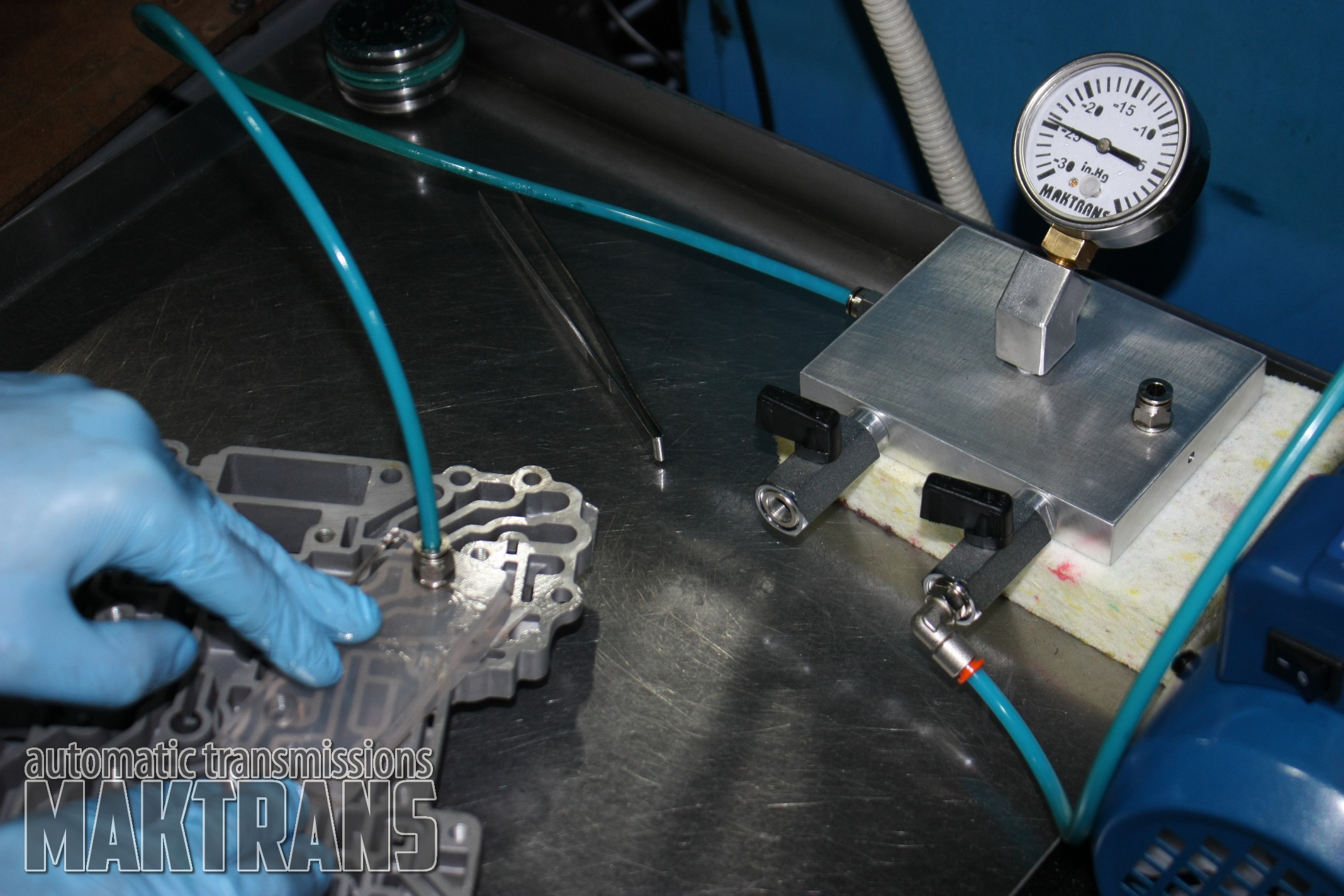

A vacuum tester is used to determine the internal wear of the hole. The device creates a low pressure zone in the diagnosed zone and the repairman, focusing on the pressure gauge readings, determines the worn sections of the hydraulic plate.

Testing

|

|

|

To restore the tightness, we use repair plungers of our own production. We manufacture on a CNC lathe of high quality aluminum, then anodize. We will replace 2 valves:

- Oversized Lockup Control Valve & Boost Valve Kit AW55-50SN AW55-51SN A750E A960E Repair Kit

- Oversized Lockup Relay Valve A750E A760E A960E AB60E

These valves are the highest loaded and with a run of more than 100 thousand need to be replaced in 95% of cases. The Lockup Relay valve often wears out so much that it can be diagnosed without a vacuum tester - hold the plunger with tweezers and stagger it - the backlash can be easily felt with your hands.

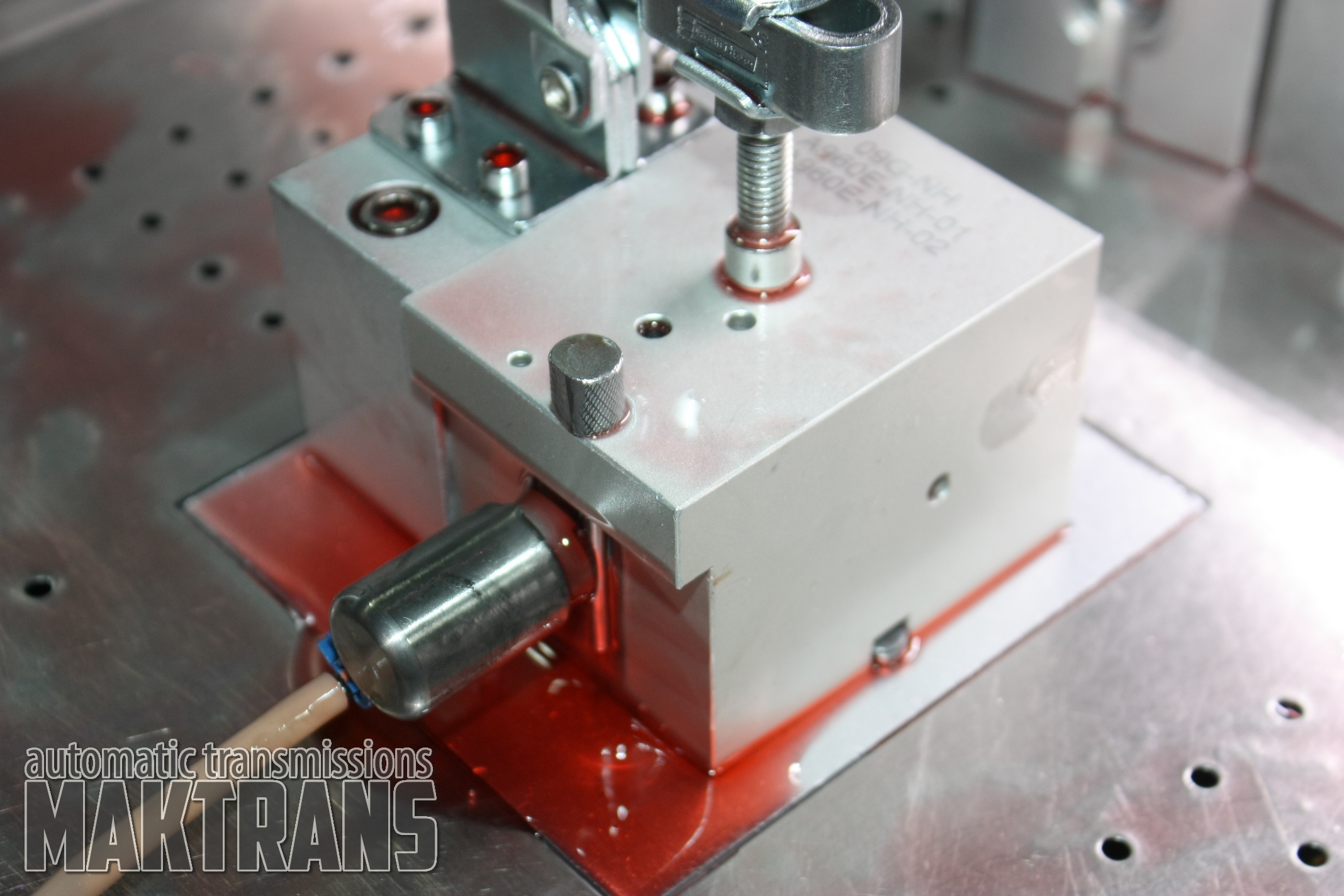

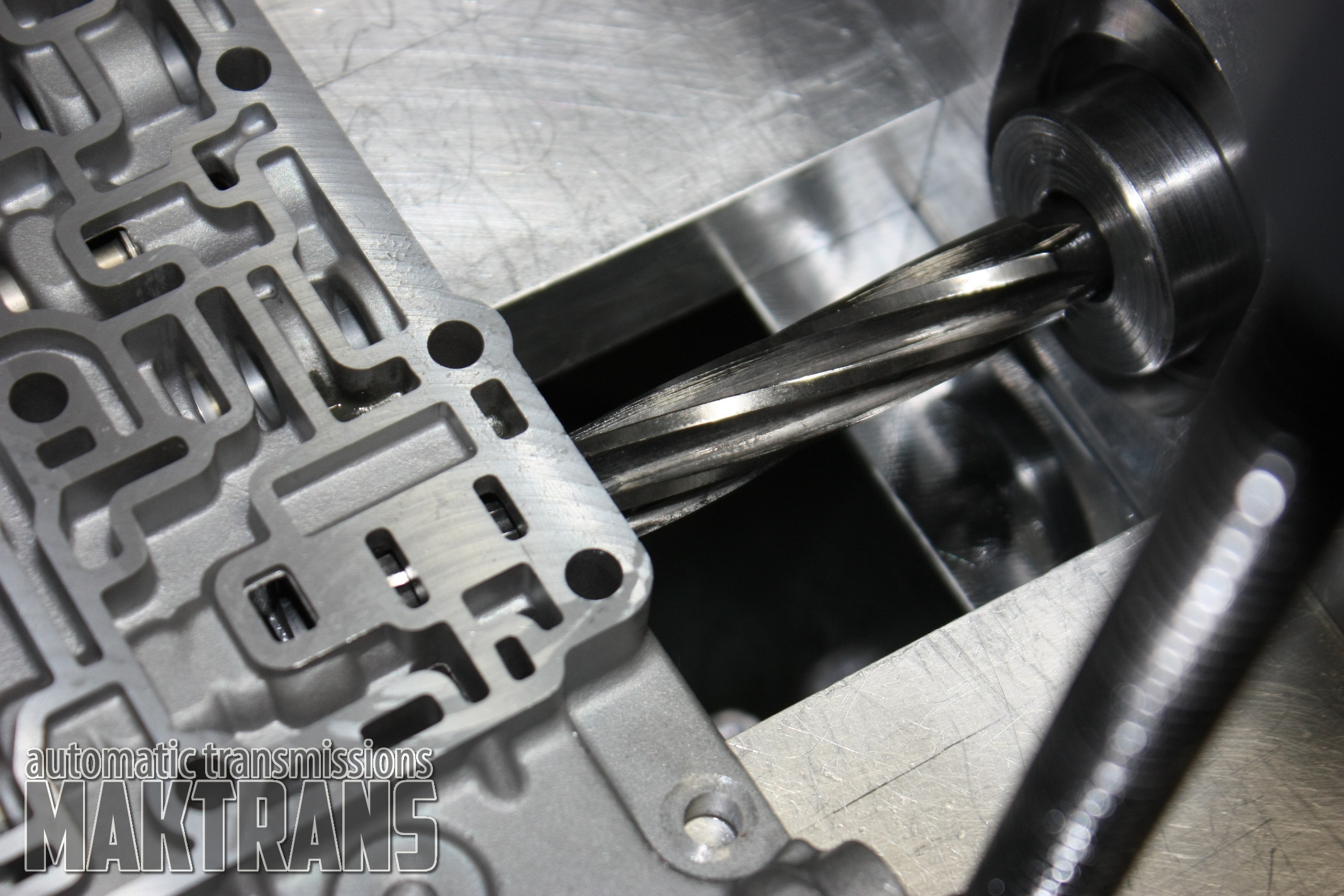

Let's drill 2 holes for repair valves right away. To do this, the plates are fixed on a special drilling machine that allows you to conveniently center the plate and adjust the sweep speed. We deploy Lockup Relay without supplying cutting fluid, since it is very important to visually control the process - you can use oil.

|

|

|

|

We take repair valves. On the left - Lockup Relay, on the right Lockup Control Valve & Boost Valve

|

|

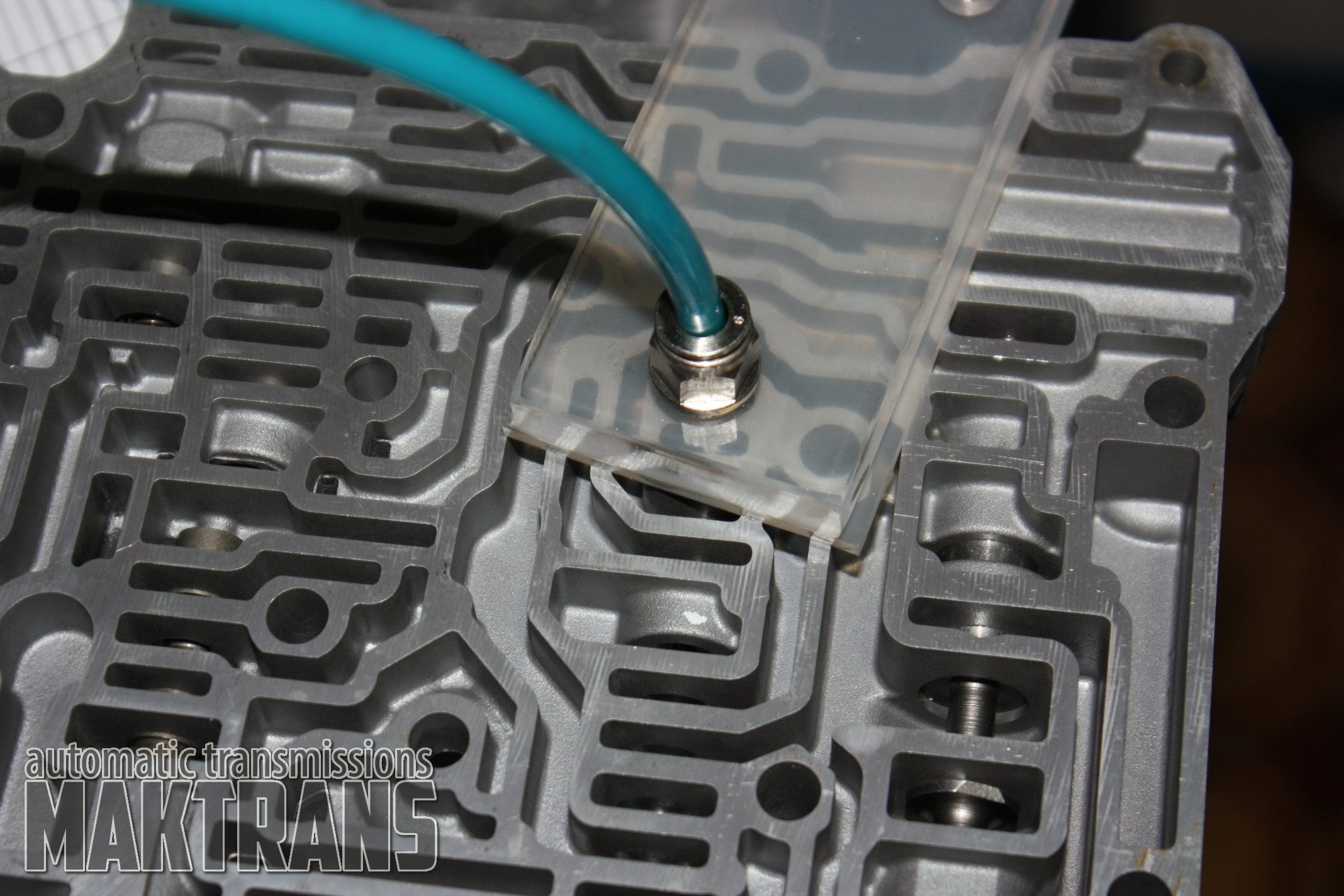

Vacuum test again-channel tightness restored.

|

|

|

Repair is completed. The valve body can only be assembled - it is easy if you have a manual or you photographed every step in the disassembly process. In the end - a couple of universal tips:

- Often, the valve body repair is part of the overhaul of the box, do not forget about the torque converter repair!

- In the process of repair, we rinse the cooling system, put a new filter and fill in new oil.

- Installing an additional radiator.

- If you need spare parts for repair, our online store has everything you need to repair ANY modern automatic transmission.

Payment

- PayPal (Payment to a PayPal account, without obtaining European VAT documents)

- Bank Transfer P2P only (Payment for private banking account, without the possibility of obtaining European VAT documents)

- Crypto Payment (If you want to make payment in cryptocurrency, without the possibility of obtaining European VAT documents)

- B2B sale with VAT ID: no VAT is charged (When buying for more than 300 euros, B2B sale with VAT IDfor countries VIES: no VAT is charged (With mandatory indication of the European VAT number and receipt of documents for the company) when buying for more than 300 euros

Shipping

We work with shipping companies like DPD, DHL, FedEx and we can ship worldwide. Shipping cost you can see during checkout and on product page (you can use button "Shipping Cost Calculator")

Would I send you the transmission to do the job or would I have to take out the valve body? Also where are you located ?

MAKTRANS

MAKTRANSHello, we need only valve body. We located in Poland.

How long takes the repair anh how much is the price for repairing A750F valve body

MAKTRANS

MAKTRANSHello, ~5 working days, ~400$