$0.00

Checkout- Brand: MAKTRANS-VB

- Product Code: 0AMVBREBUILD

Product model copied to clipboard

- Weight (kg): 10

- Availability: 20837

| Stock Place: | Availability: | Qty: |

| Poland | 10936 pcs. |

|

| Ukraine | 9901 pcs. |

|

- Product overview

- Shipping & Payment

- Questions - Answers (0)

- Related products (2)

Repair types

- Pressure accumulator cylinder repair A/T DSG 7 0AM (DQ200)

- Clutch drive solenoid repair A/T DSG 7 0AM (DQ200)

Рressure accumulator cylinder repair DSG 7 0AM (DQ200).

DSG DQ200 -7-step robotised transmission, designed to transmit torque up to 250 N * m. This model of automatic transmission is widely represented in the range of vehicles of the VAG concern with an engine capacity of up to 2 liters:

- Audi A1, A3, Q3

- Seat Altea, Ibiza, Leon

- Skoda Fabia, Octavia, Superb

- VW Beetle, Golf, Jetta, Polo, Passat, Scirocco, Tiguan, Touran

The robotised transmission is controlled by an electrohydraulic unit - mechatronic. A feature of this automatic transmission model is the high value of the hydraulic fluid pressure on the actuators. Unlike vave bodies of conventional automatic boxes, mechatronics has its own oil circuit separate from the lubrication circuit of the mechanical part of the transmission, it allows to avoid contamination of the hydraulic fluid. For transmission of control forces mechatronics uses a small amount of oil - only 1.1 liters, while the control pressure reaches 60 Bar (approximately 60 Atmosphere). In a working car, such pressure is created by the oil pump, but after the ignition is turned off, the pressure is released. To quickly create pressure after turning on the ignition in mechatronics, a special unit is used - the pressure accumulator. The battery is made in the form of a gas cylinder, inside which the pressure is 50 Bar. Thus, after the ignition is switched on, the battery shows the initial pressure in the hydraulic system, after which the oil pump adjusts the required value depending on the ambient temperature.

|

|

Structurally, the pressure accumulator is installed in the mechatronics housing through a threaded connection and sealed with a rubber ring

|

|

In case of accumulator failure, it can be replaced with a new one.

|

|

High pressure in the system, cyclic loads and fatigue of the mechatronic body material eventually lead to the destruction of the pressure accumulator seat. In the beginning, this manifests itself in the form of a long "pumping" of the mechatronics hydraulic system after the ignition is switched on, as a result of the non-standard bleeding of the pressure through the microcracks in the housing. Further operation leads to errors due to oil pressure in mechatronics. At the same time, an external inspection does not always make it possible to determine the presence of a defect.

|

|

Over time, microcracks grow in size and lead to the destruction of the mechatronics seat, which, in combination with high pressure in the battery, resembles an explosion. The consequences of such destruction can be the cause of the failure of the entire mechatronics due to contamination of the oil circuit channels by the fragments of the housing parts.

|

|

|

|

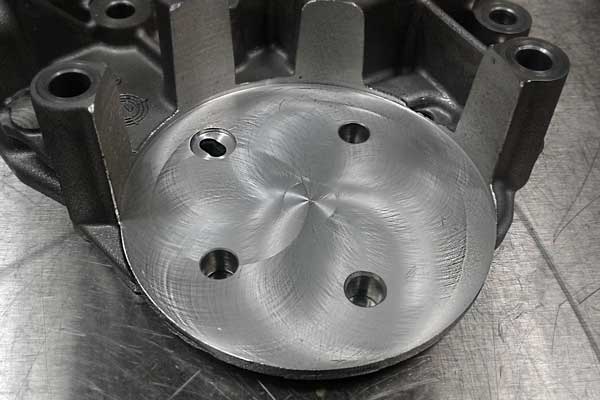

To solve the problem of microcracks increasing and to prevent the consequences of overall mechatronics destruction, Maktrans company spesialists developed a technology to strengthen the accumulator seat by using materials of increased strength. With this aim, the battery seat is prepared for the installation of a reinforced bushing by milling it on a numerically controlled machine, which provides the required level of precision in machining the surfaces of the workpiece.

|

|

The reinforced glass is made of steel and is stronger than the standard seat in the mechatronics housing (mechatronics housing material - aluminum alloy) by strength characteristics. The dimensions of the glass exactly repeat the original dimensions of the battery seat: the thread pitch, the diameter, the size of the holes for fixing and feeding the oil.

|

|

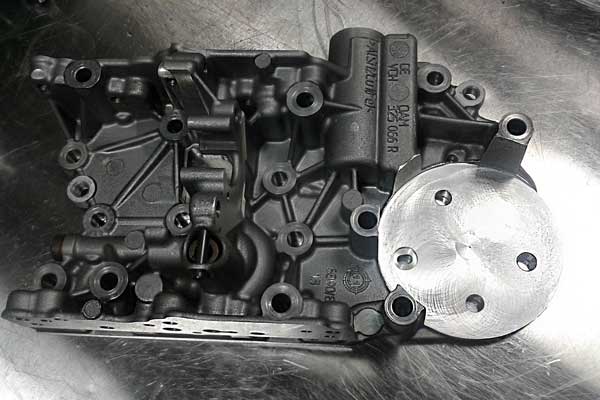

On the previously prepared place in the mechatronics housing, a reinforced bushing is installed, the design does not differ from the original in appearance.

|

|

The further assembly takes place in the normal mode using bolted connections according to the technological scheme of the mechatronics service.

|

|

After the repair, the mechatronic is connected to the mechanical part of the transmission and the car passes the test drive starting from ignition on and checking the initial pressure in the mechatronics and ending with the automatic transmission test in all operating modes.

The occurrence of pressure errors in mechatronics and a long start after switching on the ignition, accompanied by the sound of the oil pump, are the most common signs of problems with the pressure accumulator. Timely diagnosis and repair can prevent the development of a malfunction and significantly save on its elimination.

Skoda Octavia A5 1.8 TSI DSG 7 0AM (DQ200). Replacing the clutch actuator solenoid

Description of the problem.

When driving in Drive mode, bumps are felt when switching to even gears. When shifting from the first to the second gear and from the third to the fourth gear. In some cases, after the next bump , the gearbox entered into the emergency mode (flashing key on the instrument panel).

Diagnostics.

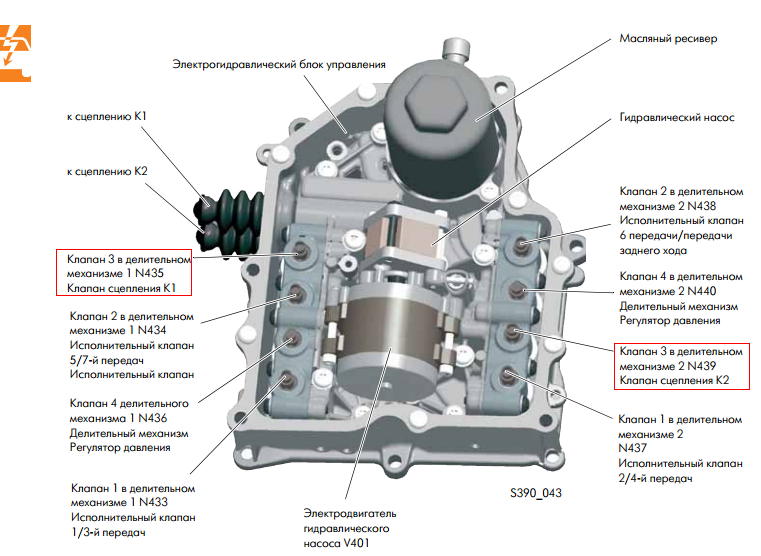

To select the strategy for troubleshooting the automatic transmission, the diagnostic tool is used first of all. Reading errors in our case showed the code P176F (Coupling 2 is inadvertently closed sporadically). Most often, this code indicates the unstable operation of the clutch actuator solenoids that are part of the electrohydraulic gearbox control unit. In the figure below, the pointers to the problem solenoids are marked in red.

Malfunction elimination.

Dismantling of the transmission electromechanical control unit (mechatronics).

Disassembly and washing of mechatronics. Visual assessment of the condition of the valve body case for the presence of characteristic defects.

Diasmantling of solenoids for testing on a special test stand.

Stand for testing the solenoids

Installing a solenoid for testing

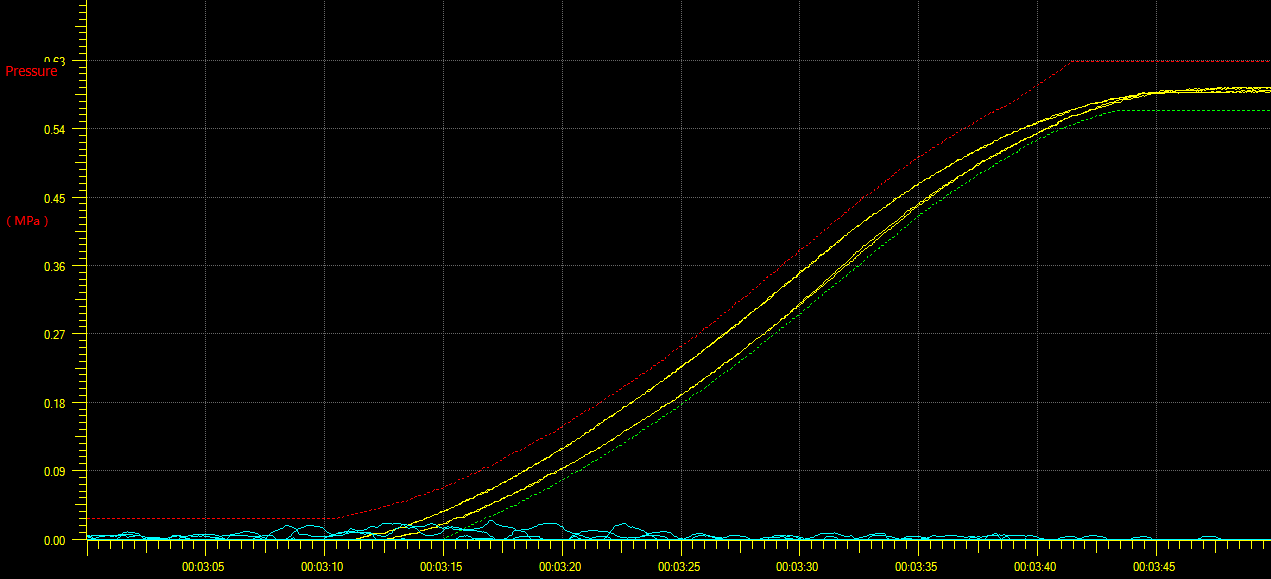

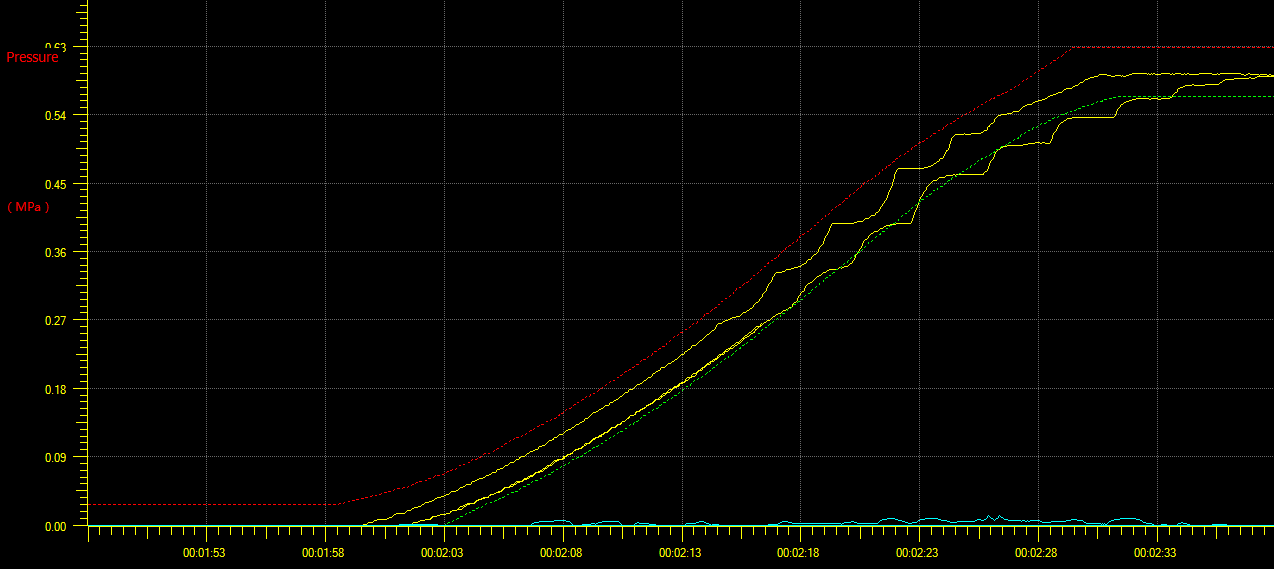

All solenoids are tested sequentially. The working schedule of a working solenoid is:

And this is a work schedule of a failed (not stable) solenoid

During the tests, a failed solenoid with unstable operation was detected. This solenoid controls the clutch K2 (the second primary shaft) on which the second and fourth gears are located. It means that unstable operation of the solenoid caused a bummp in the operation of the gearbox. This solenoid must be replaced.

After replacing the solenoid, the mechatronics assembly is performed and a preliminary check of its hydraulic system is made. The operation of the motor of the oil pressure pump is checked, diagnostic conditions are read. After carrying out the diagnostic tests, the mechatronics is installed and it is connected to the gearbox.

Result.

After replacing the solenoid, the box's operation has stabilized. Bumps when switching the second and fourth gear are not observed.

Detailed review about the repair of DSG 7

Payment

- PayPal (Payment to a PayPal account, without obtaining European VAT documents)

- Bank Transfer P2P only (Payment for private banking account, without the possibility of obtaining European VAT documents)

- Crypto Payment (If you want to make payment in cryptocurrency, without the possibility of obtaining European VAT documents)

- B2B sale with VAT ID: no VAT is charged (When buying for more than 300 euros, B2B sale with VAT IDfor countries VIES: no VAT is charged (With mandatory indication of the European VAT number and receipt of documents for the company) when buying for more than 300 euros

Shipping

We work with shipping companies like DPD, DHL, FedEx and we can ship worldwide. Shipping cost you can see during checkout and on product page (you can use button "Shipping Cost Calculator")