$0.00

Checkout- Brand: MAKTRANS

- Product Code: AWF8G45-DRM-R

Product model copied to clipboard

- Sold: 3

- Weight (kg): 0

- Availability: 997

| Stock Place: | Availability: | Qty: |

| Poland | 997 pcs. |

|

- Product overview

- Questions - Answers (0)

О

One of the main materials used in the production of transmissions is aluminum.

Manufacturers choose it for its density-to-strength ratio. Aluminum is easier to process when manufacturing geometrically complex transmission elements. It is not very heavy, which is definitely a plus when talking about the dynamic characteristics of the car as a whole.

But there is a more significant disadvantage that outweighs all the advantages - the short service life of aluminum parts.

The weak point of the Aisin Warner AWF8G45 eight-speed transmissions is the C3 / C4 Clutch aluminum drum. The reason for this is the use in one unit of components made of metals of different densities:

- The drum is light and ductile aluminum.

- The basis of the friction disc is solid steel.

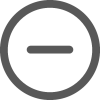

The result of such a tandem is the inevitable destruction of a part made of a less durable metal. In the photo you can see the damage left by the teeth of the steel discs on the body of the C3 / C4 Clucth AWF8G45 drum after 100 thousand kilometers.

The formation of notches provokes jamming of the disks, which entails a change in the gap between the steel and friction disks, as a result of the disks slipping, after which the drum burns out.

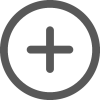

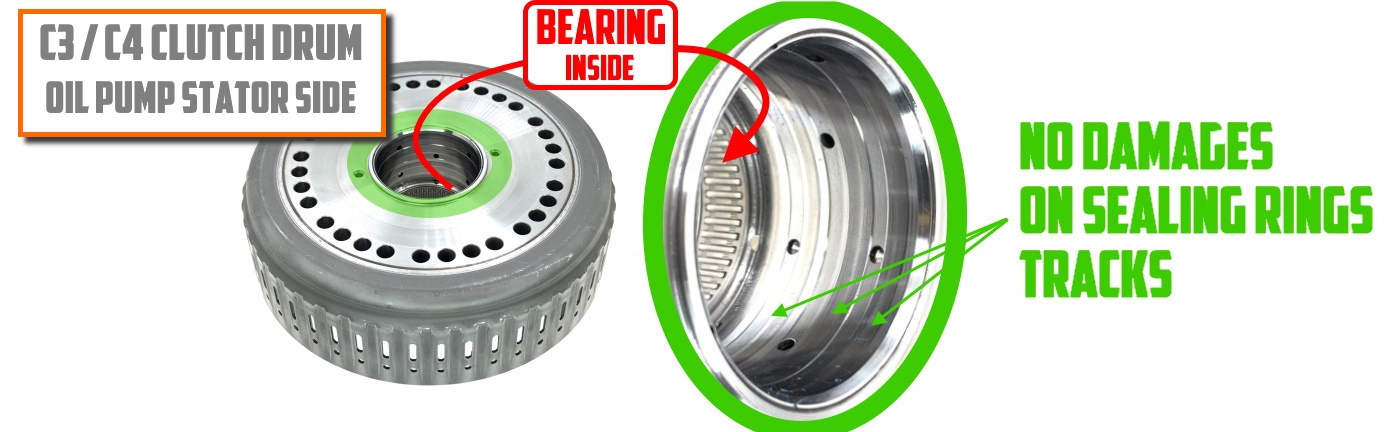

The hub side of the oil pump suffers just as much. The tightness of the drum at the hub is ensured by teflon or plastic rings that run along the inside of the drum. The wear products of transmission elements form an abrasive that, together with oil, gets into the gap between the teflon ring and the drum body and gradually saws it, increasing the gap and reducing the tightness.

The photo clearly shows signs of wear.

There are modifications of Aisin Warner AWF8G45 transmissions in which the drum is made of steel. Drum after a run of 100 thousand. km looks like new and has no damage like a similar aluminum drum.

|

|

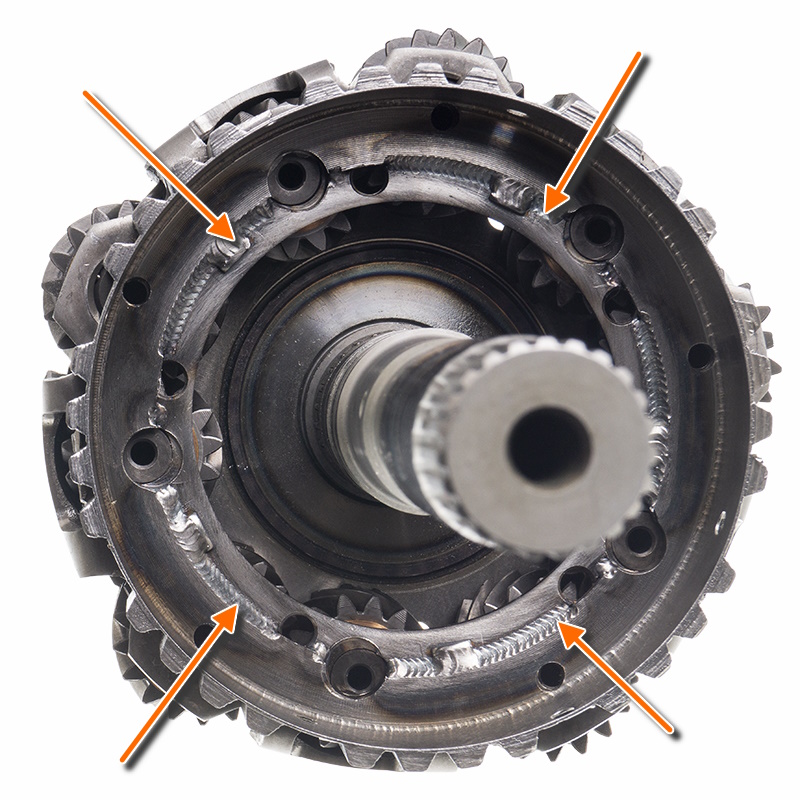

It will not be possible to install a steel drum assembly with discs instead of an aluminum one due to the difference in the outer diameters of the C4 Clucth hub.

The C4 Clutch hub used with an aluminum drum is slightly larger in diameter and has smaller teeth with a different trapezoid angle.

The difference between the hubs can be clearly assessed by looking at the friction discs.

Having replaced the friction discs, the drum “sat” in its normal place without any problems.

During testing, it turned out that the C4 Clutch hub rests against the edge of the piston, limiting its stroke, which in turn prevents the C4 Clutch package from blocking.

The problem lies in the design features of the C4 Clutch piston and C4 Clutch hub.

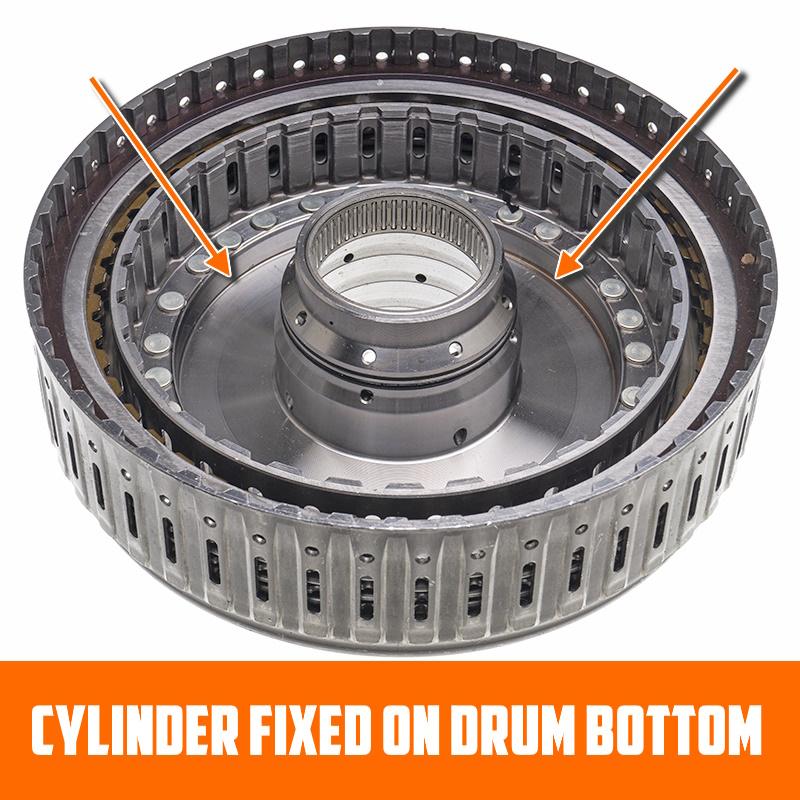

The aluminum drum contains an aluminum piston with rubber O-rings. The piston body forms a cylinder, the static piston forms part of the drum.

|

|

A steel drum contains a steel, rubber-coated piston and the drum body forms a cylinder in which a rubber-coated piston with a rubber-coated retainer operates.

|

|

Pistons are not interchangeable.

After analyzing the information received, it was decided to replace the C4 Clutch hub, which would be suitable for working with a rubber-coated piston.

We cut off the standard hub and laser welded a suitable one. The Forward Clutch hub of the TOYOTA U150 / U250 transmission was used as a donor

|

|

|

Replacing the hub solved the problem and the hub no longer interferes with the operation of the C4 Clucth clutch piston.