$0.00

Checkout-

Keeping the automatic transmission working in its original form requires careful attention to the state of the ATF fluid (oil), since the service life of the solenoids and valve body directly depends on the condition and quality of the oil in the automatic transmission.

Oils for automatic transmissions (Automatic Transmission Fluid) are very complex auto chemistry products, they have the highest requirements for density, antifriction, antioxidant and antifoam properties. Oil is responsible for different functions: it lubricates, cools, transmits torque and provides frictional adhesion, protects against corrosion and wear. The average operating temperature of ATF is 80-95 C, and in hot weather in traffic jams it can rise to 130 C and more. The design of the automatic transmission is such that if more revolutions are removed from the engine, their excess is spent on internal oil friction, which contributes to an increase in temperature. These factors lead to foaming, which creates favorable conditions for oil oxidation and metal corrosion. The variety of materials in friction pairs (steel, bronze, cermets, friction gaskets, elastomers) complicates the selection of antifriction additives, and also creates electrochemical vapors, in which, in the presence of oxygen and water, corrosive wear is activated. Under these conditions, the transmission fluid must maintain its operational properties and transmit torque.

Box elements are subject to inevitable natural wear and tear. Over time, wear products settle on the walls of the entire hydraulic system. Corrosive material, small chips from friction clutches and lock-up clutches, is an excellent abrasive for high-precision automatic transmission parts.

Reasons for the appearance:

- wear of friction and steel discs.

- wear of shafts in the place of contact with bearings.

- gear wear, gears broken.

- wear of planetary gears, wear of satellites.

- wear of needle bearings.

If the oil is dirty, the solenoid valves become clogged with wear products and all kinds of deposits.

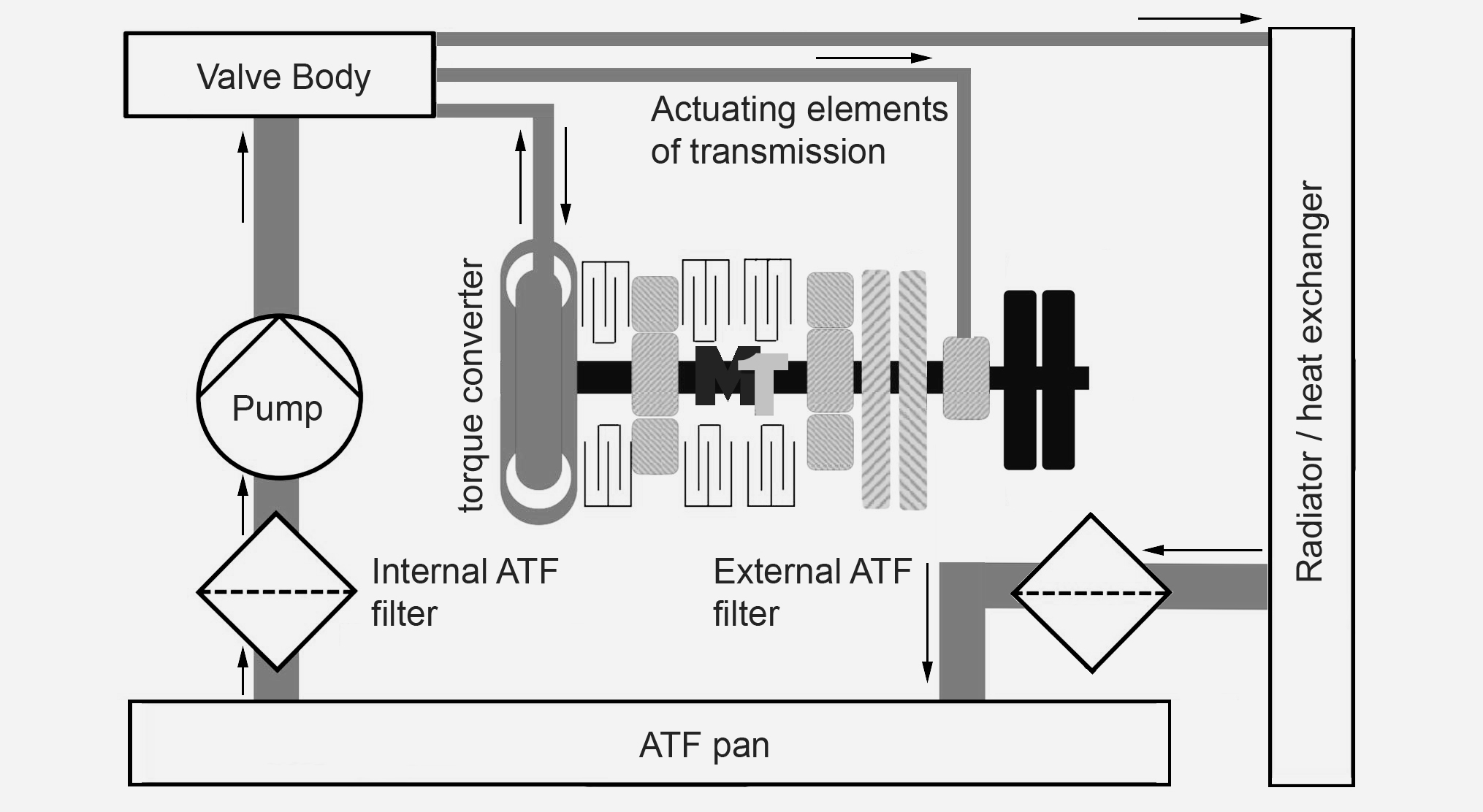

Solenoids allow the torque converter lockup clutch to turn on and off, shift gears. The solenoids are controlled by an electrical control unit, it sends electrical signals to the solenoid, opening or closing the valve. This allows the transmission oil pressure to be controlled for proper operation of the friction discs. Abrasive wear consistently increases the clearance between the valve body bore and the valve, which subsequently leads to incorrect transmission oil pressure. Incorrect pressure on the friction discs sharply increases their wear, and their wear materials again enter the oil, starting a new round in the degradation of the automatic transmission.

Add to this the increased operating temperature of automatic transmissions, in comparison with mechanical analogs, and we get conditions in which the long operation of the automatic transmission directly depends on the timely replacement and filtration of ATF (oil).

-

So, most car owners know that technical fluids and filters in a car need to be changed if you expect to continue using it after the car warranty expires.

In modern machines, a metal mesh or a felt membrane acts as a filter element.

Felt filters do a better job of filtering and retaining light fractions of wear products, but this has a downside. If the oil is heavily contaminated, the felt filter becomes clogged with fine particles and chips. The throughput of the filters drops and oil starvation begins at the pump, in the first minutes of starting, which leads to accelerated wear.

In most automatic transmissions, the filters are removable, but there are machines in which the filter is very deep inside and it is extremely difficult to get to it, these are automatic transmissions such as AW 50-55SN, AW TF-80SC, TF-81SC, on such machines we recommend immediately installing an external filter.

In situations where metal shavings are visible after removing the pallet on the magnet, a sudden change of a large amount of oil can lead to washing out the remaining shavings into the valve body, which can lead to increased wear, failure of the solenoids and valve body valves.

There are 2 approaches to changing the oil in an automatic transmission:

Partial oil change is the method recommended by transmission manufacturers. It is used for an ordinary scheduled oil update, when there is no suspicion of a malfunction of the machine. It implies a complete drain of the available volume with the removal of the sump (if provided) and the replacement of the filter. Complete oil change - done using a specialized installation. It is connected to the cooling lines of the transmission hydraulic system. The pressure unit displaces the old oil and replaces it with new one. This will require a larger volume of new oil. There is a high risk of clogging of valve body elements and solenoids with washed out light fractions of wear. Basically, the station is used when some low-quality non-original oil was poured into the box, which negatively affected the operation of the unit.

-

Additional automatic transmission filters are installed to protect the valve body, solenoids and other vulnerable parts from particles that are already in the hydraulic system. Experience shows that most often they accumulate in the radiator, therefore, on used cars, it is best to install an additional filter after the radiator. You can install an external filter at any time. But ideally, an additional filter should be added along with a complete fluid change and a new internal filter.

To install you need:

- Fittings - 4 pcs;

- Quick-detachable fittings - 4 pcs;

- Clamps - 4 pcs;

- External filter adapter for automatic transmission - 1 piece;

- Filter - 1 piece;

- Hose - 2 meters (the hose must withstand high pressure, temperature and fit in diameter).

The filter is installed after the heat exchanger, since the bulk of the deposits accumulates in it, which then should not get into the valve body.

Step 1. Locate the filter location in the engine compartment next to the transmission oil lines. Make sure there is enough space to remove the filter.

Step 2. Screw the two fittings into the filter adapter using pipe sealant.

Step 3. If your vehicle has an optional transmission oil cooler, connect in line after it.

Step 4. Cut off the required amount of hose and route it to the radiator. Do not cut the factory piping, it is better to use adapters, this will give you the opportunity to remove the filter at any time. When laying, make sure that hoses do not come in contact with fans, wear points, sharp edges and exhaust pipes.

Step 5. Insert the quick-disconnect fittings into the end of the hose and tighten with a hose clamp, one centimeter from the end of the hose.

Step 6. Insert the fittings into the end of the pipeline and secure with a clamp.

Step 7. Connect the filter by connecting the quick disconnect fittings and the "INLET" union, connect it after leaving the radiator. "EXIT" we connect in series.

Step 8. Check the clamping of the clamps. When routing hoses, make sure any bends are at the minimum radius. Hoses should not come into contact with fans, rub, come into contact with sharp edges and exhaust pipes, fix with zip ties.

Step 9. Start the engine and check for oil leaks.