$0.00

Checkout- Brand: MAKTRANS-VB

- Product Code: 5HP19VBREBUILD

Product model copied to clipboard

- Weight (kg): 10

- Availability: 1999

| Stock Place: | Availability: | Qty: |

| Poland | 1000 pcs. |

|

| Ukraine | 999 pcs. |

|

- Product overview

- Shipping & Payment

- Questions - Answers (0)

- Related products (30)

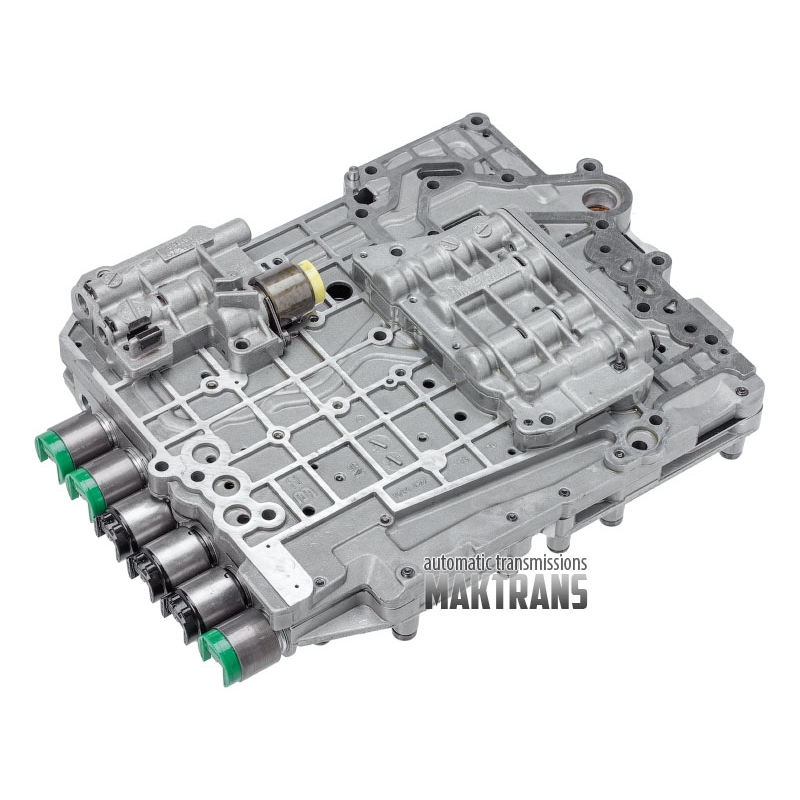

Valve body rebuild ZF 5HP19 5HP19FL 5HP19FLA

ZF 5HP19 (for BMW) and ZF 5HP19FL / 5HP19FLA (VW, Audi) - a family of 5-gear automatic transmissions developed by ZF for European vehicles of the VAG and BMW group, also fitted to some models of Jaguar and Porsche.

This automatic transmission is a very popular guest in auto services even at the moment, in spite of the fact that it first descended from the assembly line more than 20 years ago. Over the years, the repair procedure ZF 5HP19 is well studied and brought to full automaticity, known for all the weaknesses and common problems.

In this article we will review the repair of the valvebody, we will offer different solutions to the problems and tell you how the masters of Maktrans company carry out a complete rebuild procedure, including diagnostics and troubleshooting, checking and repair / replacement of solenoids, regeneration of valvebody plates using oversized plungers of own production.

For clients we offer 2 types of repair:

Turnkey repair - includes a full range of works: disassembly, defect diagnosing, repair, assembly, while we agree with the client the repair process and explain why we decided to repair this or that node and how much it costs. The pricing is completely transparent, the total cost of repairs is made up of the cost of the work performed and the consumables.

Example of calculating the cost of work performed:

Example of calculating the cost of work performed:

- Diagnostics and damage identification of the valvebody (includes disassembly, washing, vacuum testing of the hydroplate to identify worn out channels)— 100$

- Checking the solenoids on the stand, if the valvebody came in for repairs with solenoids - $ 5 per piece. Total check of 7 solenoids — 35$

- The results of diagnostics of solenoids have shown the need to replace the pressure regulator solenoid - we put the original solenoid of ZF production, the price is — 73.70$

- The vacuum test indicated a problem with the pressure regulating valve and the lubrication control valve. It is necessary to make 2 holes using our tool and install 2 oversized valves. After installing oversized valves, the plates are again subjected to a vacuum test. Reaming of one hole costs $ 20, one valve $ 11. Total - $ 62

- Valve body assembly (includes replacement of gaskets) - free of charge.

Total rebuild price is 270.70 $ - it is not fixed and can cost both more or less money, depending on the state of the valve body. We do not take money for work that we do not do.

The second option of repair is partial repair: gearbox repair man can send us the necessary hydroplate with indication of which valve to install, send solenoids for inspection and so on. There is an exchange fund for the hydroplate, send your plate - and on the same day we are sending already regenerated plate, the price policy is the same - the cost of reaming the hole + the cost of the plunger.

Now we will consider the repair process in more detail and stop at each point.

Table of contents:

• Troubleshooting and damage identification

• Repair of the valve body hydraulic part

-Leave an application for repair

Diagnostics

Repair of the valve body begins with disassembly. If you are a beginner gearbox repairman, we advise you not to hurry with the disassembly and take pictures of all the steps, namely, to pay attention to the location of small parts such as balls, springs, plugs, etc. - this can be of great help in the assembly phase.

Valve body on the stand

Disassemly

Please remember , the beginning master should be very attentive to the process of disassembly and fix each step, in the valve block there are a lot of small parts that can get lost during disassembly:

Here is what the pressure relief valve looks like

Dismounted hydraulic plate

Sometimes the problem in hydraulics can be diagnosed visually, in the photo below - the main pressure adjustment valve. The coating has worn off, it will not provide the necessary tightness and will not work.

Disassembled to separate plates, the valve body is sent to the washer.

Washing machine

We use special washers and powder, which provides high-quality cleaning and degreasing of parts. Powder is also on sale, it can be used without washing machine:

After washing,valve body parts are thoroughly blown with compressed air (liquid, oil in the channels can affect the test results) and ready to go back to the valvebody repair department for a vacuum test.

Vacuum Tester

Vacuum tester - a device that allows to determine the wear of plunger channels (and plungers) in hydraulic plates, the principle of operation is extremely simple - the steam channel + plunger is checked for wear based on the amount of air through the gaps. The device creates a low pressure area in the required area of the hydroplate and the manometer readings allow to determine deviations from the norm.

You can also buy a tester from us:

• Leakproofness tester for valve body plates by vacuumizing

We start the vacuum test:

The ideal indicator is 25 inches of mercury, we take it as the standard.

Test beginning

The results of the vacuum test of the main pressure plunger, visual diagnosis confirmed problems with the channel and plunger.

Testing has shown the necessity of installing oversized plungers of main pressure, lubrication control and modulator valve. Further in the section "Repair of the hydraulic part" of this article, let us consider the installation of the main pressure plunger.

We now turn to the diagnosis of solenoids.

Equipment for testing solenoids

When testing solenoids "Maktrans" company specialists use equipment that allows to plot the solenoids working in close proximity to real ones, namely testing in different temperature modes, solenoid control is performed in the same way as the native electronics of automatic transmissions .

Different temperature test modes are necessary because there is a possibility that the solenoid plunger will only jam to the hot one, or vice versa - it works well in the heated box, but with a cold start there will be problems.

We install the solenoid in the stand and begin the test

The program draws a schedule for opening / closing the solenoid, which allows you to evaluate the performance of its electrical and mechanical parts. Below you can see 2 graphics, a working and faulty solenoid. On the second chart, you can see the problems with closing the plunger, such a solenoid will not work properly.

Working solenoid chart

График неисправного соленоида

Test results allow you to decide whether to replace a certain solenoid or several. Almost every repair is accompanied by a replacement of the pressure solenoid, it looks like this (a second generation solenoid with a yellow connector, the first generation with a black connector):

The EPC pressure solenoid

This solenoid is the most heavily loaded, since it regulates the main pressure in the transmission and most often fails. Also, problems with it can be indicated by symptoms such as thump / jerk when Drive mode is activated or when changing from 5 to 4 gears. If you continue to operate with such symptoms - the plunger can jam in the open position, which will lead to an increase in pressure in the clutch packs and they will collapse,as the first packet A will suffer.

Hydraulic part repair

Vacuum inspection of the valve body showed us the problem plunger, we proceed to repair.

We sell and we use oversized plungers and reamers of our own production. The plungers are made of high quality aluminium on CNC machines, the coating is anodized, the strength and wear resistance is completely identical to the original factory plunger.

Repair plungers produced by "Maktrans"

Pressure regulator valve reamer

The machine for drilling holes, allows you to adjust the speed of the reamer.

Valve body plate adjusting and fixing

An important point is cooling. It is necessary to cool the area that is reamed.

We rearrange the cooling direction according to the reamer move. This will extend the resource of the tool, and will ensure the reliability and quality of the hole reaming .

Hole reaming process

Reamed hole

We insert the oversized valve and repeat the vacuum test.

Vacuumization result corresponds to the factory parameters, we repeat all operations for the remaining plungers and collect the valvebody!

That's what the entire repair process looks like. In further materials, we plan more detailed consideration ofindividual repair processes, such as the repair of solenoids, the correct valve body assembly, vacuum testing and so on.

One more thing- ZF 5HP19 overhaul repair necessarily involves repairing of the torque converter, you can also repair it in "Maktrans" company:

Another common problem ZF 5HP19 - cranking the oil pump bushing due to overheating, solution two - replacing the pump with a new one or replacing the bushing, if the pump state allows this operation:

- Oil pump ZF 5HP19FLA 95-up 1060210024 01V321241 – Audi

- Oil pump – BMW

- ZF 5HP19 ZF 5HP19FLA oil pump bushing replacement

Payment

- PayPal (Payment to a PayPal account, without obtaining European VAT documents)

- Bank Transfer P2P only (Payment for private banking account, without the possibility of obtaining European VAT documents)

- Crypto Payment (If you want to make payment in cryptocurrency, without the possibility of obtaining European VAT documents)

- B2B sale with VAT ID: no VAT is charged (When buying for more than 300 euros, B2B sale with VAT IDfor countries VIES: no VAT is charged (With mandatory indication of the European VAT number and receipt of documents for the company) when buying for more than 300 euros

Shipping

We work with shipping companies like DPD, DHL, FedEx and we can ship worldwide. Shipping cost you can see during checkout and on product page (you can use button "Shipping Cost Calculator")

![Solenoid kit ZF 5HP19 0501316463 0501210019 0501210725 [7 solenoids in the kit] Solenoid kit ZF 5HP19 0501316463 0501210019 0501210725 [7 solenoids in the kit]](https://maktrans.net/image/cache/catalog/Artem92/5HP19-00912-X1-228x228.jpg)