$0.00

Checkout- Brand: MAKTRANS

- Product Code: PLATE-MB-V1

Product model copied to clipboard

- Weight (kg): 2

- Availability: 1

| Stock Place: | Availability: | Qty: |

| Ukraine | 1 pcs. |

|

- Product overview

- Shipping & Payment

- Questions - Answers (0)

The 722.6 transmission, also known as the 5G-Tronic, is a five-speed automatic transmission that has been used in various Mercedes-Benz models, including the commercial line known as the Sprinter. Despite the fact that the transmission is quite well designed and reliable, breakdowns still occur, especially in commercial use.

Commercial vehicles are subject to increased loads on vehicle components and assemblies in comparison with civilian operation.

The transmission takes on significant loads, especially in light-duty Mercedes-Benz Sprinter truck models with twin rear wheels.

For some reason, it is generally accepted that such a paired arrangement allows you to take on board a larger amount of payload, since the load will be distributed over 4 wheels (paired arrangement, two wheels on each side), and not two as in the standard version.

Without a serviceable transmission that will carry the required loads, the number of wheels does not matter.

The main problem with the 722.6 Mercedes-Benz Sprinter transmission lies in the torque converter.

The torque converter is a rather complex structural transmission unit, consisting of three main components:

1. Pump wheel:

Which is driven by the rotation of the engine and creates a flow of hydraulic fluid inside the torque converter.

2. Turbine wheel:

Which is connected to the drive wheels of the vehicle and uses the flow of hydraulic fluid to transmit torque to the wheels.

3. Reactor wheel or stator:

Which directs the flow of hydraulic fluid between the pump and the turbine, optimizing torque transmission.

In the 722.6 transmission, the turbine wheel (No. 2 in the figure) is connected to a spring damper whose task is to dampen torsional vibrations in the moment and ensure smooth traction while maintaining traction characteristics.

The Sprinter experiences spring damper failure more often than other Mercedes-Benz models with the 722.6 transmission.

Мы нашли и активно применяем уникальное решение которое помогает избежать проблем с гидротрансформатором на долго.

Решение кроется в установке усиленного гидротрансформатора от более мощных бензиновых двигателей Mercedes-Benz c объемами от 4.4L до 5.5L.

Почему именно этот "бублик"?

Данный гидротрансформатор имеет усиленный демпфер с более мощными пружинами, как в диаметре так и в сечении прутка, что обеспечивает "переваривание" высоких оборотов и мощностей бензинового двигателя рассчитанного под воздействие высоких оборотов.

Это то что нужно для обеспечения тяговых нагрузок коммерческих, дизельных, малотоннажных грузовых автомобилей Sprinter. Практика показывает что данное решение продлевает жизнь гидротрансформатора в 2-3 раза в сравнении с использованием стандартного.

We have found and are actively using a unique solution that helps to avoid problems with the torque converter for a long time.

The solution lies in installing a reinforced torque converter from more powerful Mercedes-Benz gasoline engines with volumes from 4.4L to 5.5L.

Why this particular unit- torque converter?

This torque converter has a reinforced damper with more powerful springs, both in diameter and in the cross-section of the rod, which ensures “digestion” of high speeds and power of a gasoline engine designed for high speeds.

This is what is needed to provide traction loads for commercial, diesel, and light-duty Sprinter trucks. Practice shows that this solution extends the life of the torque converter by 2-3 times compared to using a standard one.

Simply replacing one torque converter with another will not work due to design features. The reinforced torque converter is ~ 18 mm wider than the standard one.

It is necessary to carry out a set of modifications related to size compensation relative to the transmission seat.

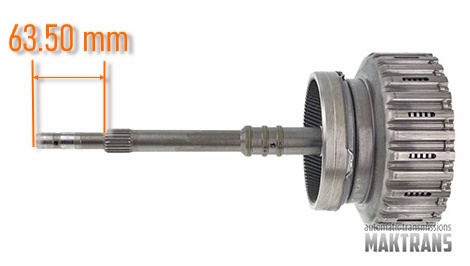

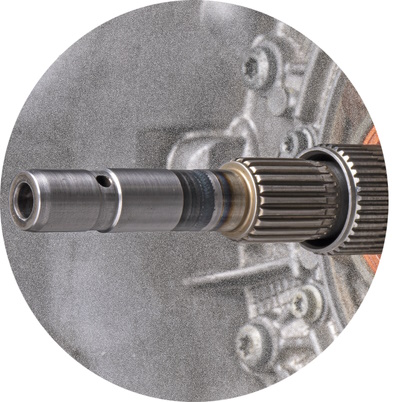

1. Due to the difference in the width of the torque converter, to ensure lock-up operation, we install an input shaft with an extended spout (63.50 mm) that ensures oil supply to the lock-up clutch.

|

|

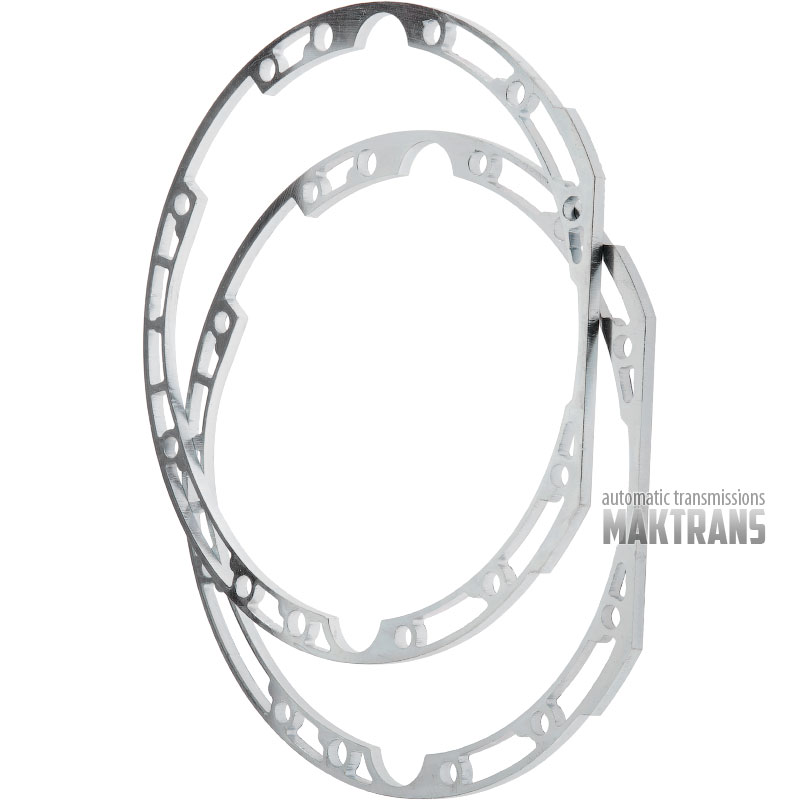

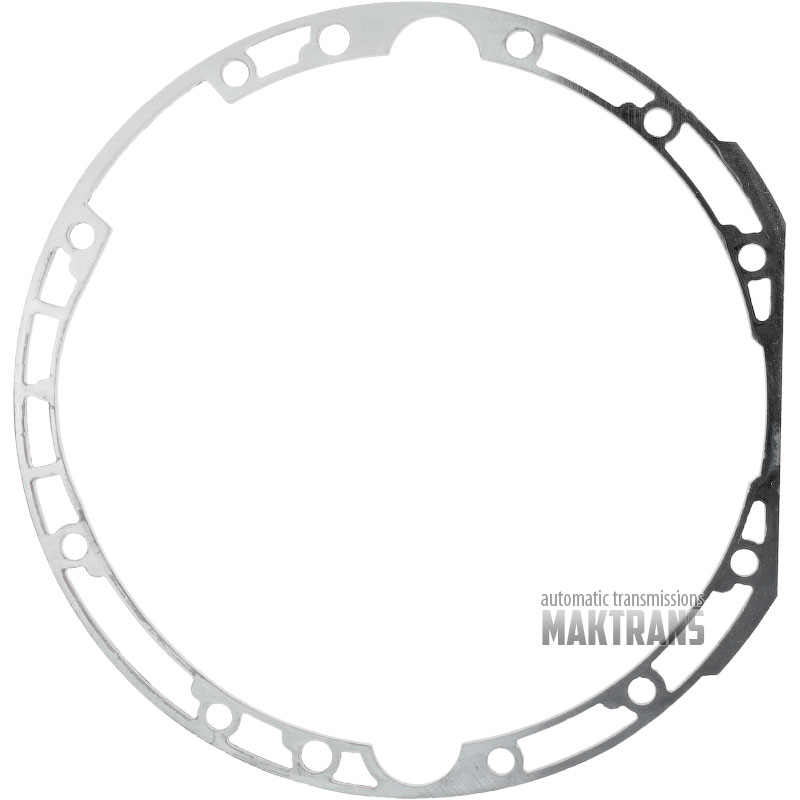

2. To compensate for the difference in the thickness of the torque converter, we install two steel spacer plates, 8 mm each, between the engine and transmission.

|

|

But then the rear mount of the transmission mount is shifted 16 mm back and the standard holes do not coincide with the mount on the body side member.

3. To interfere with the supporting structure of the body, we shorten the rear transmission mounting bracket by 16 mm and laser weld everything.

|

|

After the work has been done, the transmission is installed in its normal place.

Payment

- PayPal (Payment to a PayPal account, without obtaining European VAT documents)

- Bank Transfer P2P only (Payment for private banking account, without the possibility of obtaining European VAT documents)

- Crypto Payment (If you want to make payment in cryptocurrency, without the possibility of obtaining European VAT documents)

- B2B sale with VAT ID: no VAT is charged (When buying for more than 300 euros, B2B sale with VAT IDfor countries VIES: no VAT is charged (With mandatory indication of the European VAT number and receipt of documents for the company) when buying for more than 300 euros

Shipping

We work with shipping companies like DPD, DHL, FedEx and we can ship worldwide. Shipping cost you can see during checkout and on product page (you can use button "Shipping Cost Calculator")